all (30) maximizing uptime (17) optimizing tool life (13) choosing a sawing machine (11) costs & benefits (10) sawing different materials (8) automating a process (6) FAQ (4) other (2)

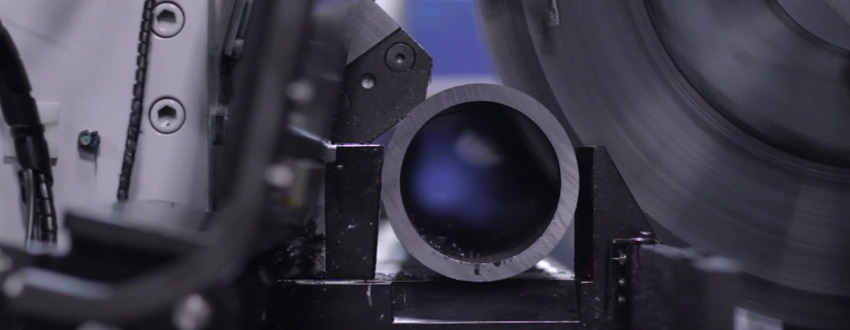

High Production Layer Saws for cutting Multiple Tubes or Bars

By cutting multiple bars or tubes in layers to increase productivity

- Read More | Comments (0) | Oct 16, 2020

Reading Chips Part 2

When operating a high production circular carbide saw quite a bit of process information from the cut chips on the shop floor can be gathered.

- Read More | Comments (0) | Apr 21, 2020

Reading Chips

When operating a high production circular carbide saw quite a bit of process information from the cut chips on the shop floor can be gathered. One fact which is not intuitive if one has never thought about it is the change of the chip thickness. When measuring the chip thickness with a caliper the value is usually higher than the set chip load per tooth! …

- Read More | Comments (0) | Jan 20, 2020

4 Ways to Reduce Vibration in Carbide Saws

Here are four ways to help reduce the damaging effects of vibration in your sawing processes.

- Read More | Comments (0) | Feb 07, 2019

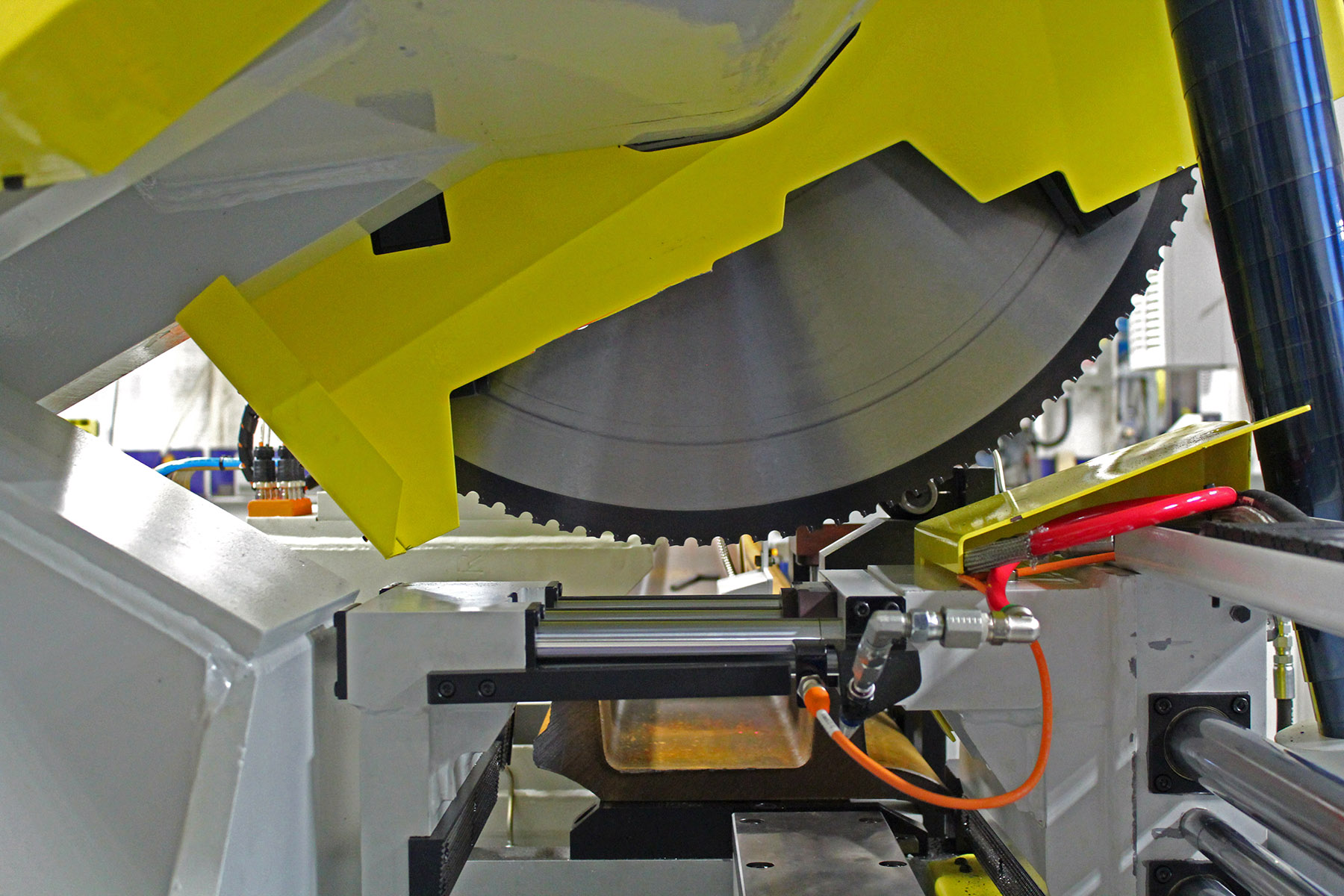

Heavier Carbide Saws Versus Lighter Standard Saws for General Machining

If machine is rigid enough to avoid breakage, the price is reasonable, and the production cost (tool life) acceptable, the lighter standard saws will dominate in quantities compared to heavier vertical or horizontal saws.

- Read More | Comments (0) | Jan 08, 2019

When to Use a Slide Saw vs. a Pivot Saw?

Your floor space and layout, budget, and customer needs will determine if a carbide slide saw or carbide pivot saw is best for your machine shop operations.

- Read More | Comments (0) | Dec 03, 2018

Systems for Length Measurement in Metal Bar, Tube, Billet, Rail, and Plate Sawing

Posted by Chris Rindels

There is a lot to consider when selecting the right length measurement system for your application. It is a matter of discrimination on how accurate your measuring needs to be and the costs benefit of each method that is available.

- Read More | Comments (0) | Nov 26, 2018

Selecting the Right Material Handling System for Your Industrial Sawing Process

Investing in the right material handling system for your sawing application can improve safety and productivity of your overall sawing processes.

- Read More | Comments (1) | Nov 25, 2018

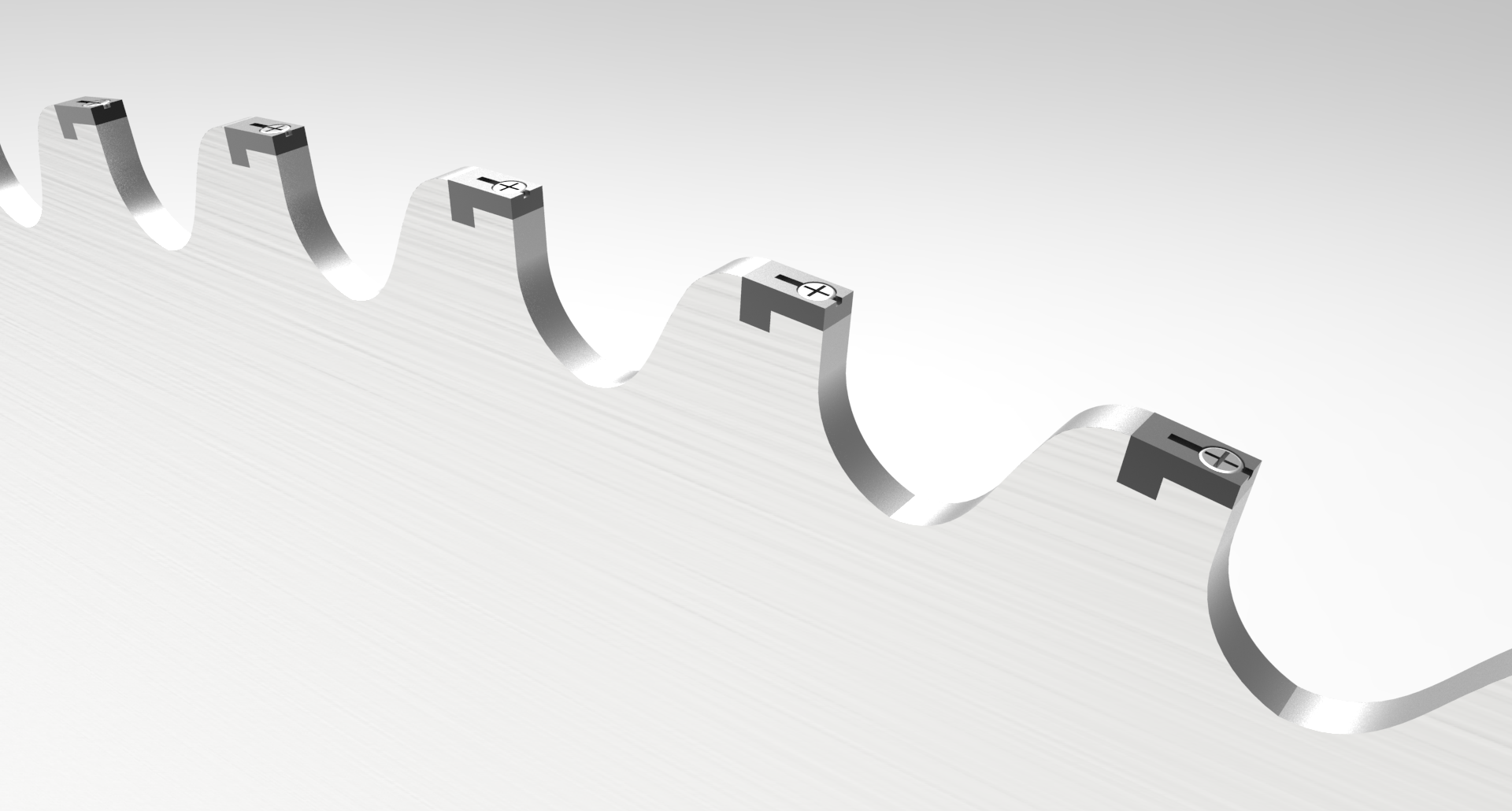

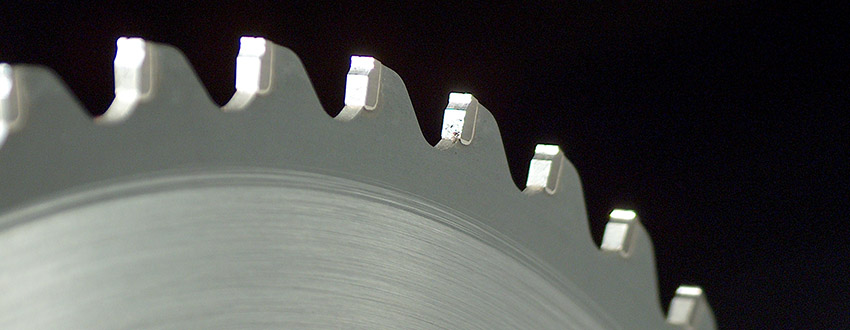

Carbide-Tipped Saw Blades Offer Flexibility & Just-In-Time Production

Carbide-tipped blades increase tool life, provide faster cutting rates, and decrease production costs

- Read More | Comments (0) | Sep 27, 2018

Vibration Analysis for Carbide Sawing Machines

Vibration analysis for carbide sawing machines is crucial for auditing blade health and quality cuts.

- Read More | Comments (0) | Sep 27, 2018

Infographic: Rail Fabrication Process with Rail Sawing and Drilling

The manufacturing process for rail production involves several steps to ensure the rail's durability and resistance to cracking.

- Read More | Comments (0) | Aug 15, 2018

How to Cut Costs Using Different Types of Carbide-Tipped Circular Saw Blades

Carbide-tipped circular saw blades are offered in three versions with different cost structures.

Updated September 2019

- Read More | Comments (0) | May 09, 2018

Why Some Material Load Tables are Overloaded with Cost

Heavy material infeed systems in production sawing systems are often over-engineered in an attempt to avoid severe damage from dropped loads. The downfall? The potential for significant cost increases.

- Read More | Comments (0) | Apr 27, 2018

Why Flood Cooling of Carbide Teeth Won't Work on Carbide Cold Saws

The carbide tips of a circular saw blade crack under extreme temperature changes, demonstrating why a flush coolant system won’t work on carbide cold saws.

- Read More | Comments (0) | Apr 20, 2018

Circular Saw vs. Band Saw: Which One is Best for You?

Let’s cover the differences between circular saws and band saws, and how to choose which one is best for your operation.

- Read More | Comments (1) | Apr 13, 2018

Automating Manufacturing with Rail Sawing and Drilling Processes

Posted by Chris Rindels

Combination machines with material handling streamlines rail sawing and drilling processes -- providing more throughput, increased quality and efficiency, and improved viability.

- Read More | Comments (0) | Apr 06, 2018

Why Minimum Quantity Lubrication is Used in Cold Sawing

Minimum Quantity Lubrication (MQL) is used in cold sawing to prevent heat build-up through friction reduction to keep both the material and the blade cool during the sawing process.

- Read More | Comments (0) | Mar 28, 2018

Why is a Circular Metal Saw Called a Cold Saw?

Circular cold saws allow both the material and blade to remain cool during the sawing process by transferring the generated heat to the chips.

- Read More | Comments (0) | Mar 23, 2018