High Volume Capabilities

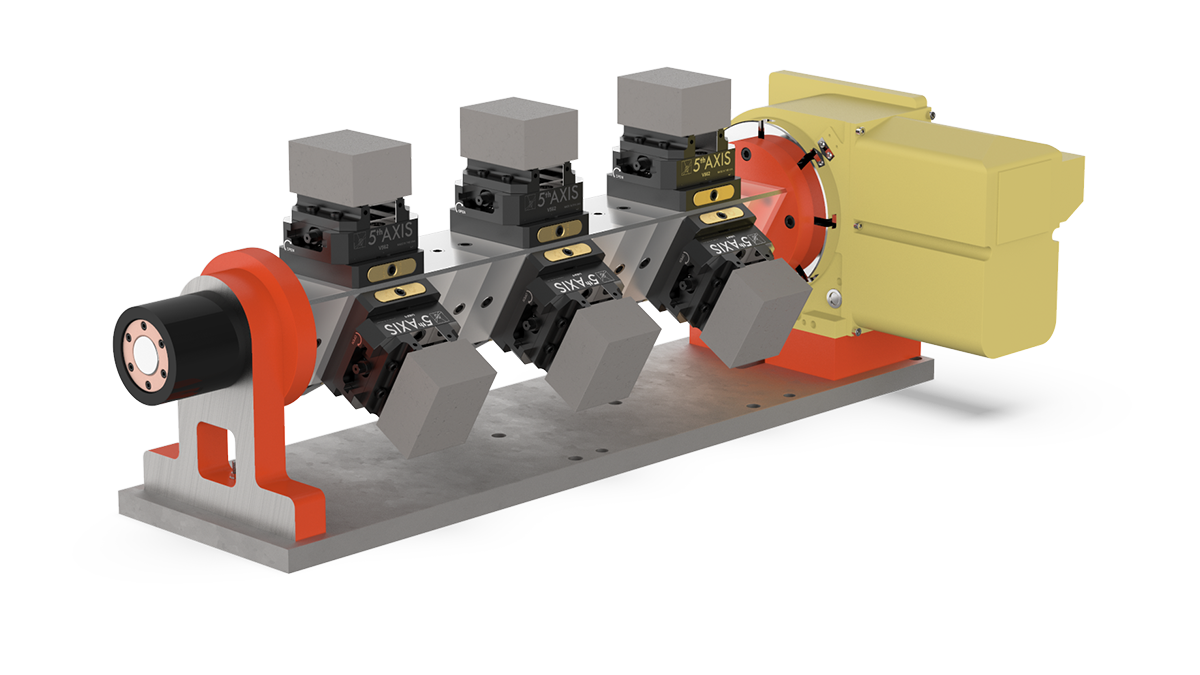

3, 4, and 5-Axis Capabilities

Self-Centering Vises

5th Axis Is Changing the Industry Standard - Workholding Evolved

Don't Feel Limited By Your Current Setup. Unlock new possibilities with 5th Axis' quick-change system designed for 3, 4, and 5-axis tables. Developed by machinists for machinists, our workholding products are engineered to thrive in the demanding conditions of the machining environment.

Stop Limiting Your Setup

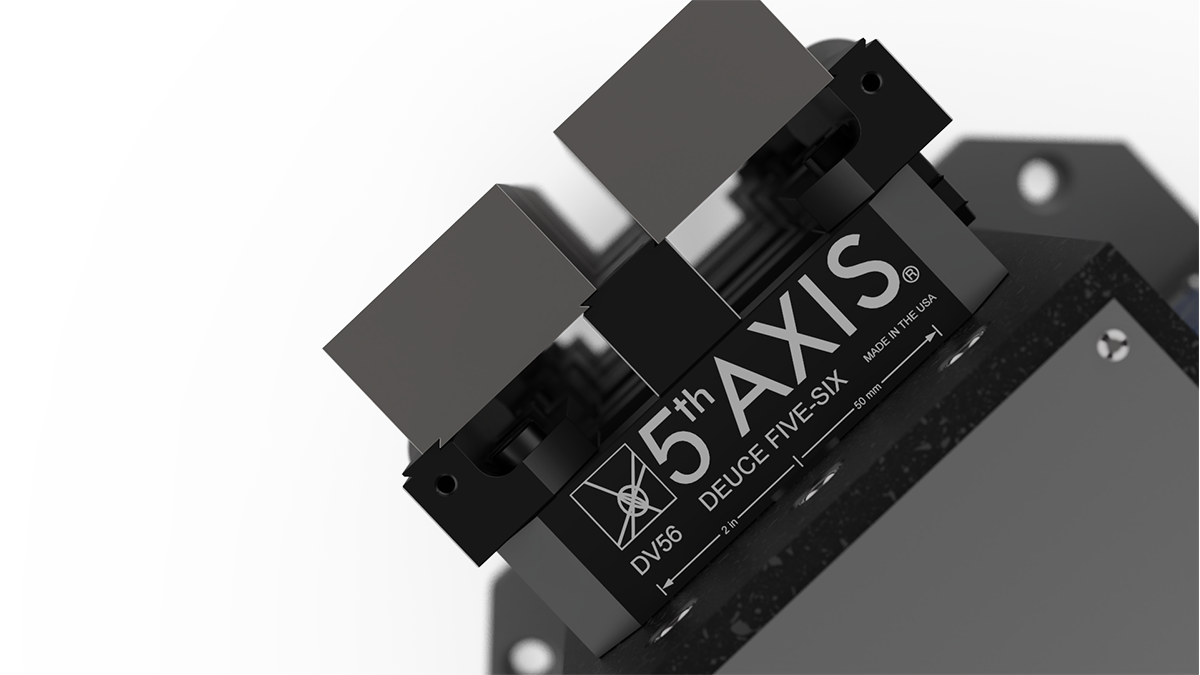

Made in the USA

All 5th Axis products are proudly manufactured in the USA, using the finest quality American materials.

Built by Machinists

Benefit from the collective expertise of our team, comprised of experienced machinists and engineers, who have contributed their knowledge to develop the highest quality workholding solutions.

Unbeatable Quality

Each 5th Axis product undergoes rigorous in-house testing and daily use to meet our strict reliability standards.

Endless workholding options can be overwhelming

We help you determine the best approach to maximize throughput

Get in touch with our team of expert fixture designers for a consultation. We take the time to understand your unique machining challenges and develop tailored solutions using top-quality workholding products from leading brands.

Our most frequently asked question?

How would you hold it?

We take the guesswork out of workholding. Our staff specializes in turnkey integrations working engineer-to-engineer with our workholding partners so you can:

▶ Maximize throughput

▶ Minimize set ups

▶ Scale your operations.

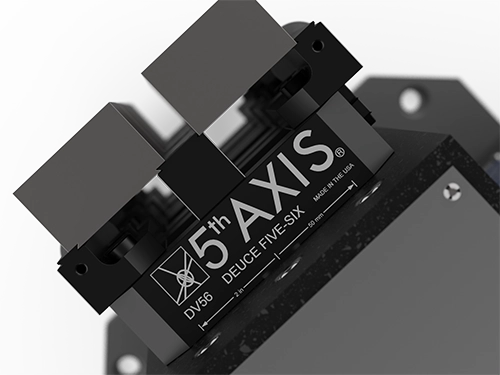

5th Axis Vise Systems

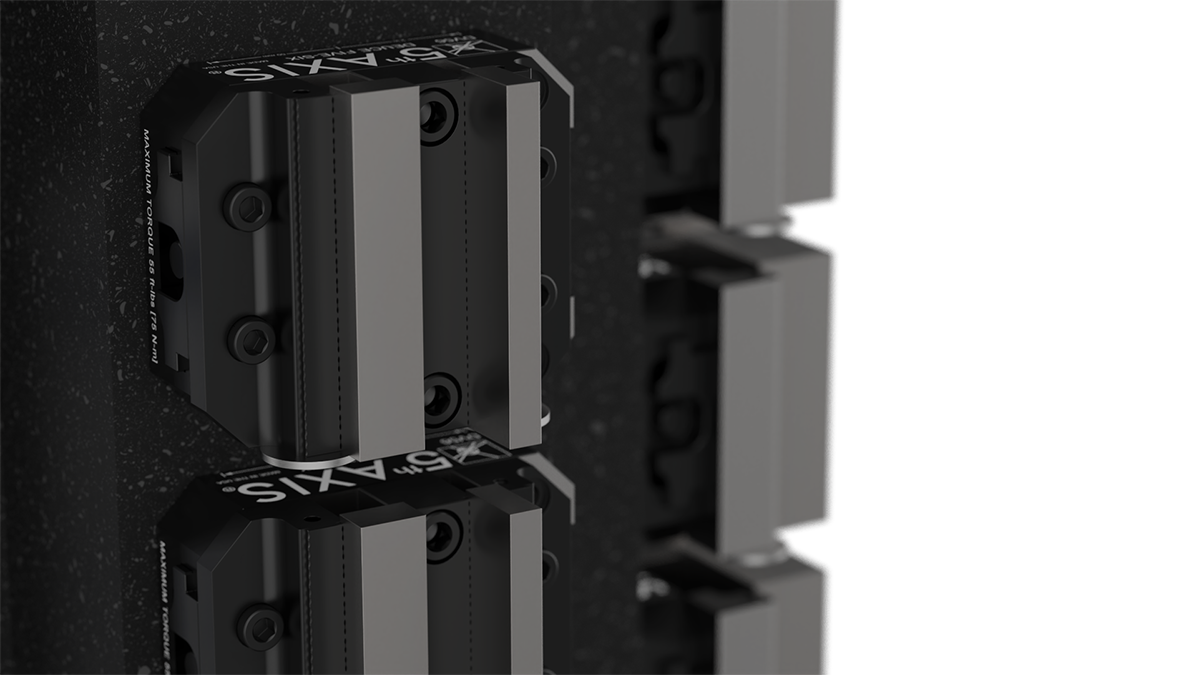

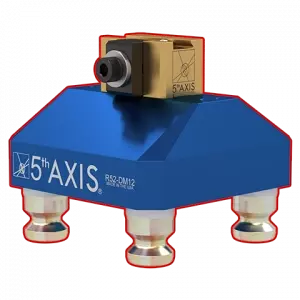

RockLock Quick Change System

Standardize your setups. Stop building custom adapters and subplates for every new job that comes into the shop. Job changeover becomes simple and repeatable with the RockLock system, saving you time and money.

Explore RockLock Systems

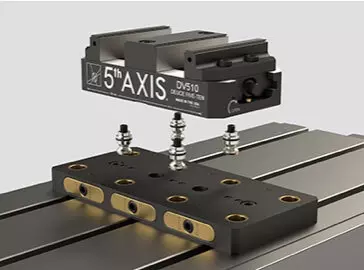

Double Station Vises

Make your existing equipment more efficient by running multiple parts per cycle. Hold larger parts with the DV510, or load up on smaller parts with the DV75150X.

Explore Double Station Vises

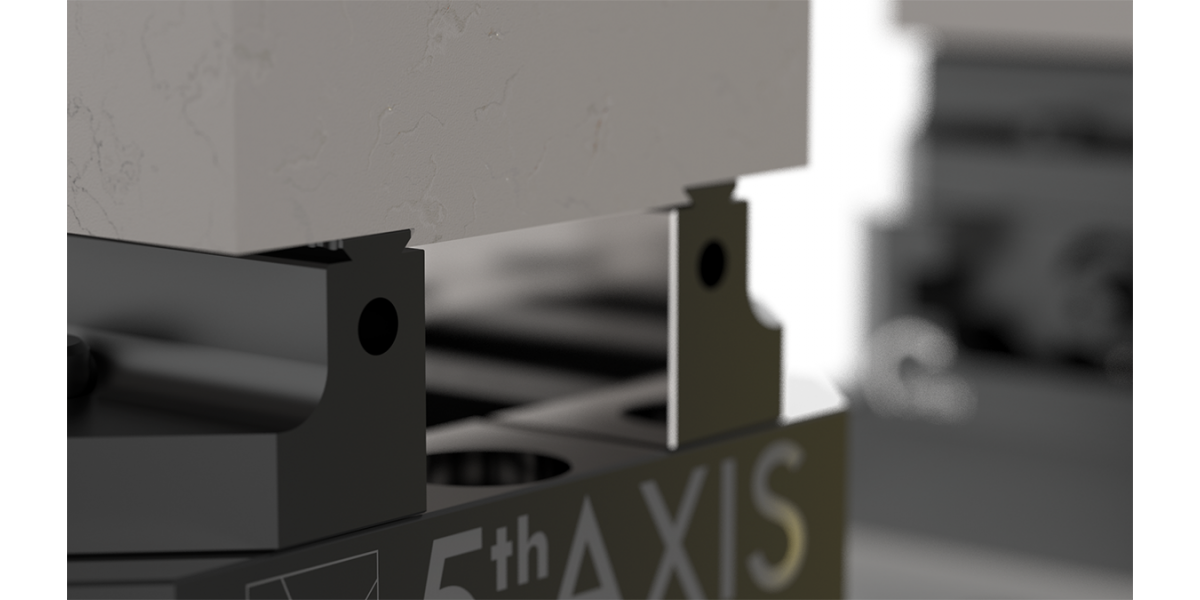

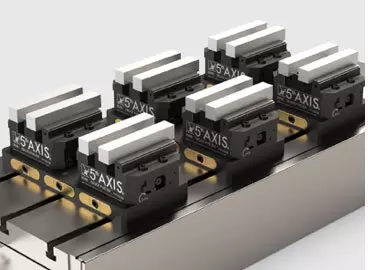

Self-Centering Vise Solutions

Jaws hold close on center. The left- and right-handed leadscrew. positions your workpiece in the center of the vise with exceptional accuracy. Centering Repeatability of 12.7 µ (.0005″)

Explore Self-Centering Vises

5th Axis Dovetail Fixtures

Dovetailing reduces the amount of material you need to purchase via traditional clamping methods. Not only do you waste less of your stock, but dovetailing also reduces part deformation due to excessive torque; dovetails spread clamping force more evenly through the part and use downforce instead of lateral pressure.

Explore Dovetail Fixtures

Top Tooling

Collection of dovetail kits, double-station vise kits, and self-centering vises in both metric and inch versions.

Explore Top Tooling

Alignment Pallets

Master pallet that guarantees accuracy of the RockLock system. Used during initial setup or if setup is moved from one machine to another.

Explore Alignment Pallets

Dovetail Cutters

Dovetail cutters used to machine the angled grooves (dovetails) into a workpiece. Creates a strong and secure area for clamping while minimizing raw material waste.

Explore Dovetail Cutters

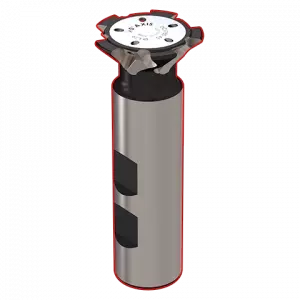

Round Bar Fixtures

Quick and efficient fixture manufactured from hardened alloy steel designed to hold different diameters of round stock.

Explore Round Bar Fixtures

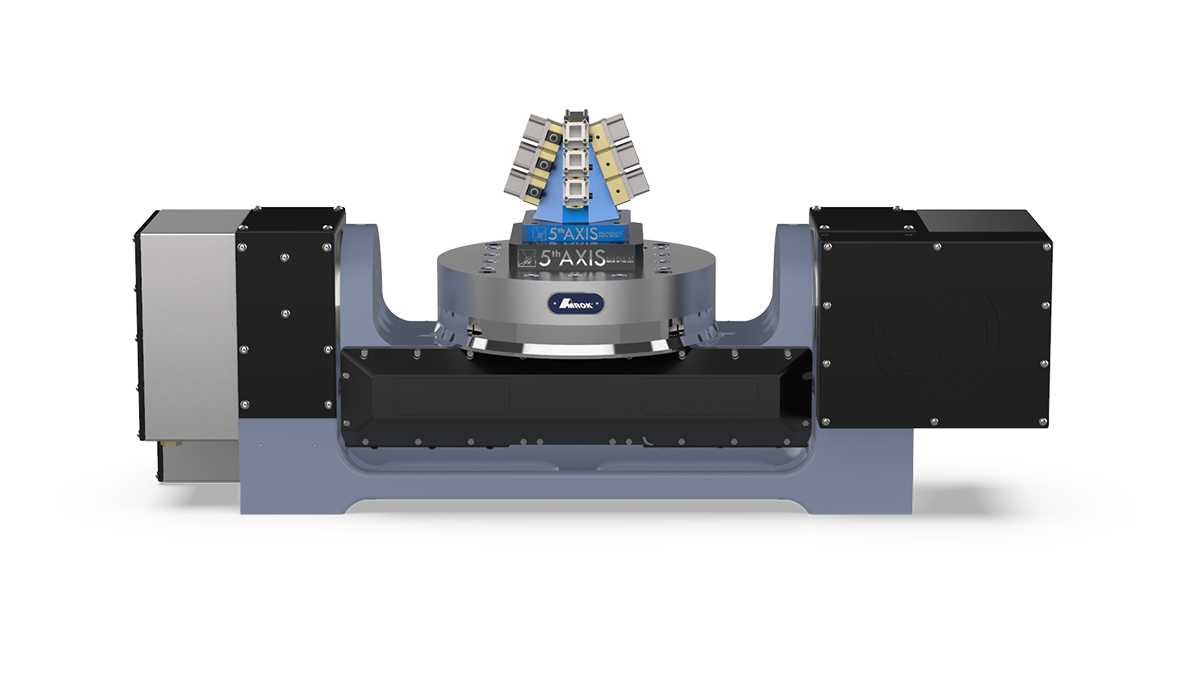

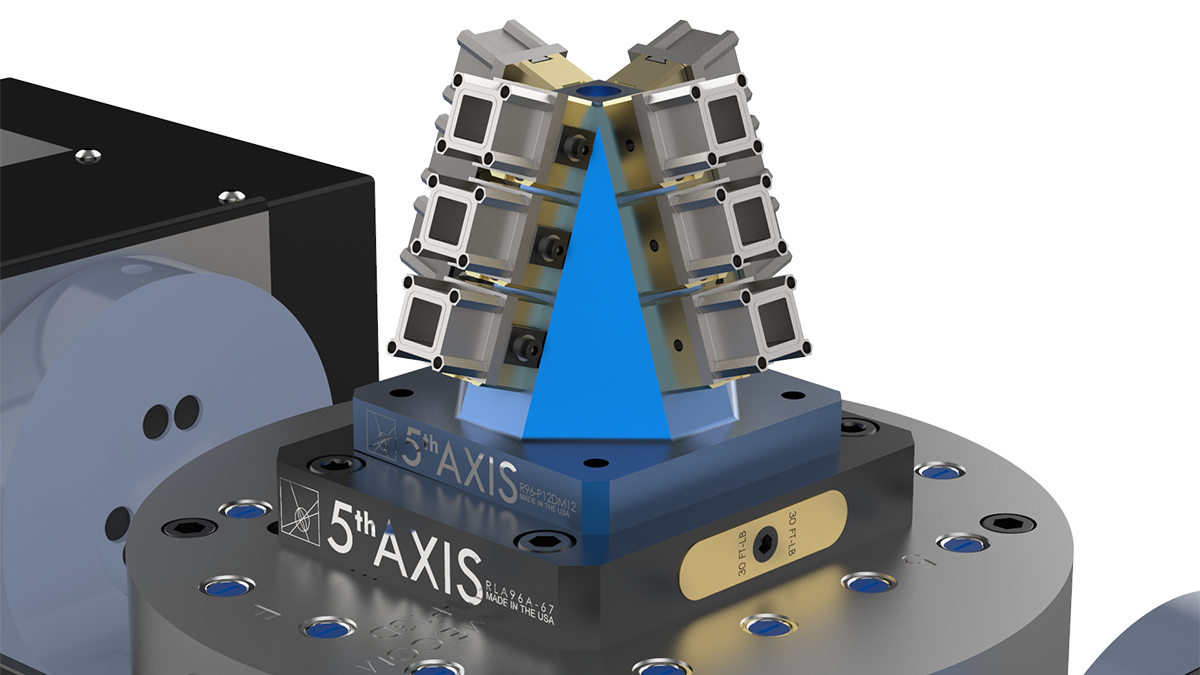

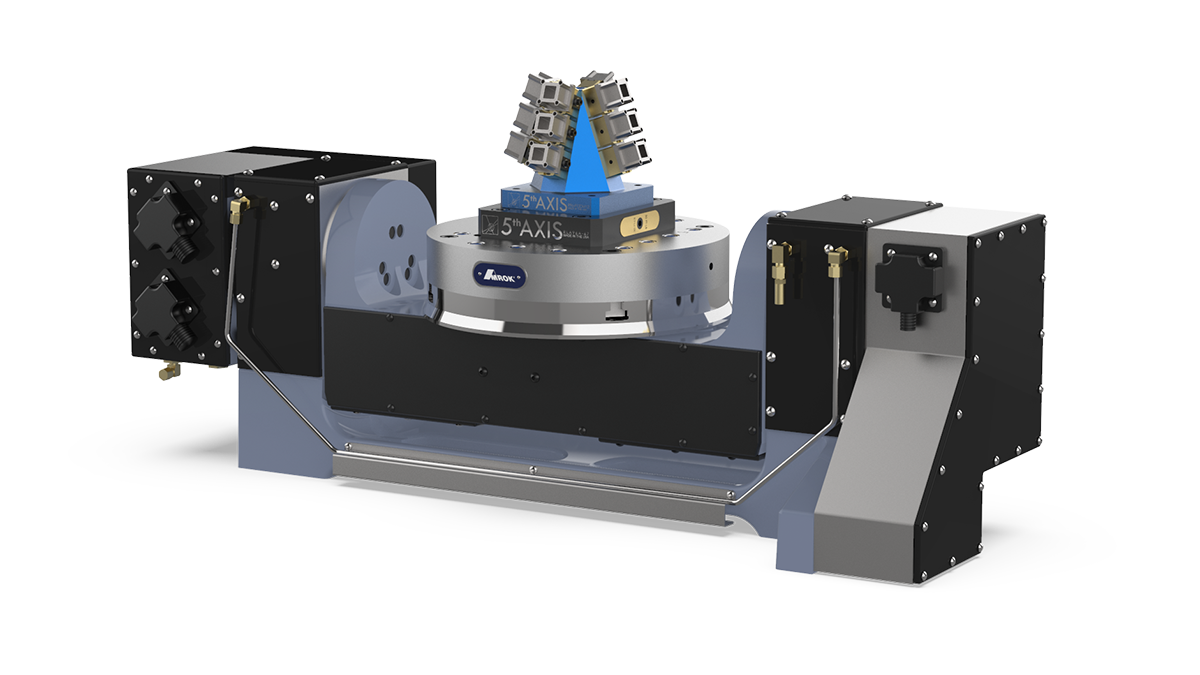

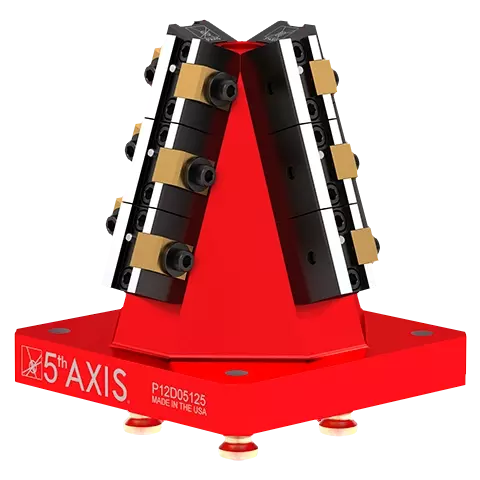

5th Axis Multi-Fixture Mounts

Multi-fixture, tombstone- and pyramid-style mounts designed to increase throughput while maintaining a small footprint. A great addition for small, 3-, 4-, and 5-axis machine setups.

Explore Multi-Fixture Mounts

Accessories

Collection of accessories including self-centering, double-station, and gripper jaws, pull stud sets, vise adapter plates, and more.

Explore Accessories