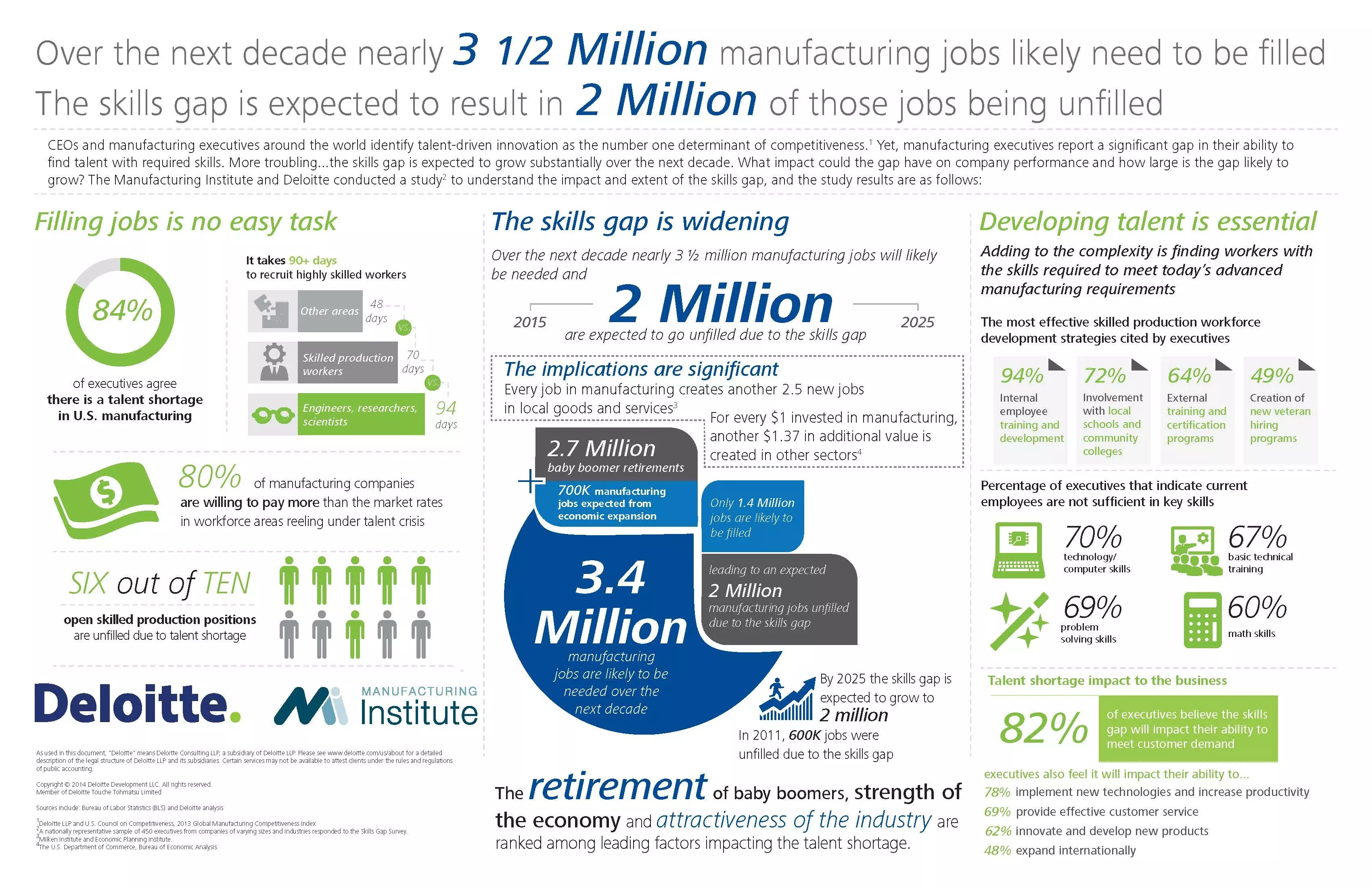

The Root Cause for the Industrial Skills Gap is a Matter of Interest

Jul 02, 2018Manufacturers are joining forces with community leaders and educational institutions to provide hands-on opportunities to high school and college students in an attempt to close the gap, but robust apprenticeships are only solving part of the problem. Perhaps the root cause of the skills gap is an interest gap stemming from younger generations’ lack of interest in learning the techniques for manufacturing opportunities.