Compact Toe Clamps

- Home

- >

- Mitee Bite

- >

- Compact Toe

Compact Toe

|

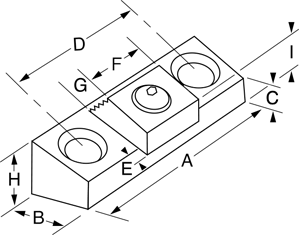

This cam action fixture clamp provides positive down force while using very little space on a fixture. Work pieces can be clamped in series by using the back surface of a clamp to locate the next work piece. The hardened steel clamping element has both a smooth surface for machined work pieces and a serrated clamping surface for rougher work. The height of the clamp can be adjusted by milling the slot deeper in the fixture plate. |

MetricE† is the distance needed between the front of the clamp base and the work piece.

I* The distance from the top of the washer to the bottom of the clamp body. Drill and tap the centerline of “B” for mounting holes. |

D* – A milled slot wider than D dimension will insure clamp remains in line with workpiece. Clamp sides should not come in contact with slot walls during expansion.

F† The distance needed between workpieces for clamp clearance. Drill and tap mounting hole on the center of F dimension.

F† The distance needed between workpieces for clamp clearance. Drill and tap mounting hole on the center of F dimension.

See It In Action

Mittee-Bite Compact Toe Clamp Applications

Loading products...