Flying High: Developing a Custom Fixturing Solution for a Jet Component Manufacturer

AME designs and builds turnkey workholding fixtures to client specifications. Our engineers support product development from start to finish to ensure the results meet all requirements.

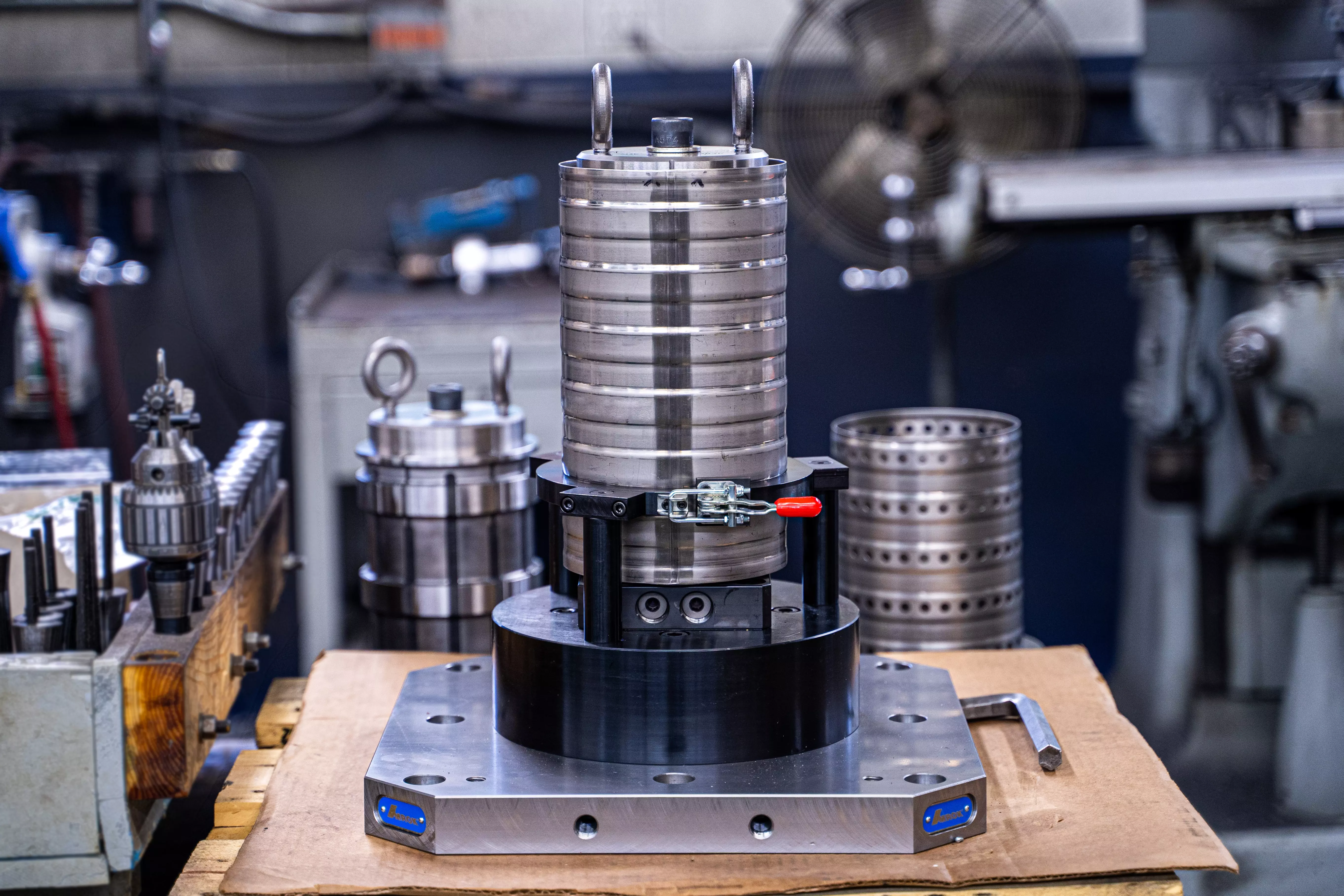

Recently, AME engineers partnered with a client to develop a custom manual collet fixture for a cylindrical jet part. The company manufactures parts and assemblies for the aerospace industry and required a precise solution to machine one of their components.

THE NEED

Our client’s need was for a fixture on a horizontal machining center. The idea was simple—this collet needs to hold a cylindrical metal part in place while nearly 200 holes are drilled into it by the machine. However, the part is thin-walled and curved, which presented a challenge while machining. The piece could not be damaged or moved around while being milled.

With a properly designed collet fixture to hold it in place, the result is a precise, jet-ready component.

THE SOLUTION

What the AME team developed and built was a collet fixture that securely holds the cylindrical part on the ID (inner diameter) of the cylinder. This ensures that the part is securely held, also supporting the thin-walled part while machining. A collar attaches to the bottom of the part and assists in loading and to provide axial locating on the fixture.

To clamp and unclamp, the operator attaches the collar in place and tightens a bolt at the fixture’s top. Facets of the collet then expand, locking the piece onto the fixture without damaging its thin metal wall. From there, six rows of holes are drilled into the part, and the top and bottom edges are machined as well. Once the machining is complete, the cylinder is deburred on the collet fixture while another is being machined.

While primarily made of spring and hardened steel, the collet also features an epoxy adhesive seal. This seal expands and contracts with the collet and keeps any chips from entering it.

THE END RESULT

Ultimately, this manual collet fixture provides a secure and thorough workholding solution for its specific use. It locks a fragile, thin wall part in place and protects it from any damage during the machining process. The fixture protects itself from any chip buildup or damage as well, ensuring a long life.

Designed, manufactured, assembled, and tested in-house, AME’s manual collet fixture is now a vital part of this client’s manufacturing process.