Custom Low-cost Fixturing for the Automotive Industry

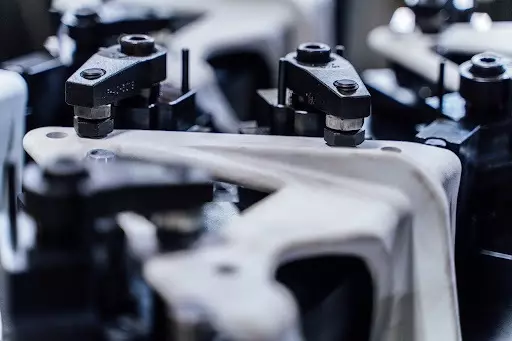

One of the process optimization partners in the automotive industry presented Advanced Machine & Engineering (AME) with a challenge: design a low-cost, custom CNC fixture for a low volume run of a heavy-duty automotive part.

The Challenge

The Challenge

The end customer was reluctant to invest in an expensive automatic workholding system for a low volume production run. They reached out to one of AME’s workholding integrators for a solution.

Typically, manufacturing facilities rarely invest in a custom fixture when they have a low production run or they haven't finalized the design on the part in question.

The Solution

The end customer wasn’t ready to invest in automatic and intricate fixtures due to bad projected ROI. AME’s design and build workholding engineers designed a simple custom manual fixture that reduced the investment by 75%.

The End Result

The End Result

AME delivered a simple and low-cost stop-gap solution, allowing the customer to uphold their manufacturing quality even during low volume manufacturing or interim design stages.