VP of Business Development—Rod Locks & Press Safety,

Machine Design Components

Office:

+1.815.316.5219

Email:

shane@ame.com

Product Manager, Rod Locks & Press Safety

Office:

+1.815.316.5217

Email:

nickroeling@ame.com

There are several environmental factors that can disrupt the effectiveness of your rod lock or safety catcher if you fail to consider them.

Units that are subject to extreme weather conditions have several options available, such as special sealing made with more durable materials, different housing materials, and oil filling to prevent internal corrosion in the case of contamination from the outside.

Corrosion-resistant materials such as stainless steel and electroless nickel plating are often incorporated in harsh environments to prevent leakage and/or outside damage.

high vibration

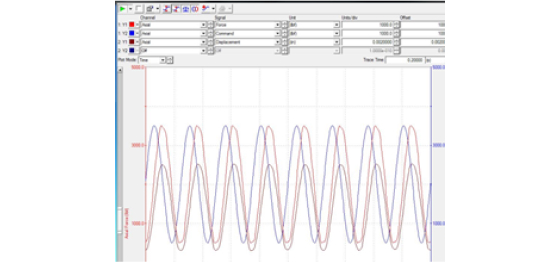

High vibration can cause several internal failures that warrant additional testing based off of the data provided by the factory to the manufacturer. The vibration can provoke issues with bearing materials causing them to break or weaken. If high vibration is an issue, our team can help determine if applicable and correct product selection.

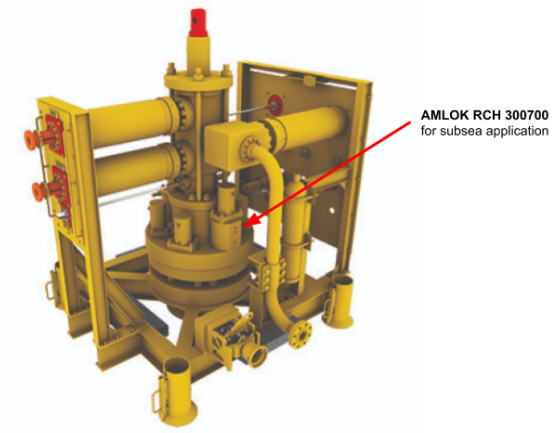

submersible applications

Applications that are submersed completely in water or other chemicals require additional sealing and oil filling options. Oil filling and sealing prevent outside contaminants from leaking into the unit therefore preventing corrosion.

extreme temperatures

Whether freezing cold or blistering hot, special Viton seals can be used for extreme temperatures. They have a specialized polymer that is designed to not get too brittle in extreme cold conditions and not melt in extreme heat.

In fact, the Viton seals are designed to operate between -4ºF (-20°C) and +401ºF (+205°C) depending on the grade. It can take even higher or lower temperatures such as -22ºF (-30°C)/-49ºF (-45°C) and +446ºF (+230°C), but for shorter working periods.

The SITEMA and AMLOK operating temperatures are 0° to +140ºF (+60°C). If application temps are out of this range, then please consult factory.

caustic and food grade environments

Caustic and food-grade environments can be challenging. High acid environments could degrade and disintegrate normal seals, so special materials and options must be considered to avoid corrosion.

This would be what is referred to as washdown applications. Applications where customers maintain a clean environment such as food or pharmaceutical industry. Special materials and seals would likely need to be used to ensure durability.

Other environmental factors could include high moisture or salt spray applications that would require housings and seals made of special materials like stainless steel or electroless nickel plating.

While your environment needs to be considered when looking into a new safety catcher or rod lock system, SITEMA and AMLOK have a variety of customizable solutions and a team of engineers to make sure the proper system is put in place for your application.