Machining & Configurations for Tooling Columns

AMROK® tombstones, tooling columns, and plates are manufactured to the highest precision and quality standards with our precision tolerances.

- Inserts allow positioning and clamping in every hole with co-axial positioned bushings.

- Assures high wear resistance and replaceability with hardened precision bushings.

- Replacement bushings and insert kits with an extraction tool are offered if needed.

| Tolerance | Precision |

|---|---|

| Flatness (tombstones & plates) | .0005 / 12x12 |

| Parallelism (plates) | .0005 / 12 Max .002 total |

| Perpendicularity | .0008 / 12 Min .001, Max .002/48 |

| Surface Finish | 63 RMS |

| Face Thickness | ≤18” = ±.001, >18” = ±.002 |

| Tapped Holes (non accumulative) | ±.005 |

| Precision Bushing I.D. | -0 / +.0006 |

| Precision Bushing Concentricity | 0.0001 |

| Bored or Precision Bushing Hole to Adjacent Hole | ±.0005 |

| First Row Bushing Hole Location from Datums | ±.001, ±.002 (Epoxy Mineral tombstones) |

| Bored or Precision Bushing Hole Spacing (non accumulative) | 0-10 ±.0005, 10-20 ±.0008, 20-30 ±.0010, 30-40 ±.0012 (for aluminum, add 50% to these tolerances) |

Machining Options

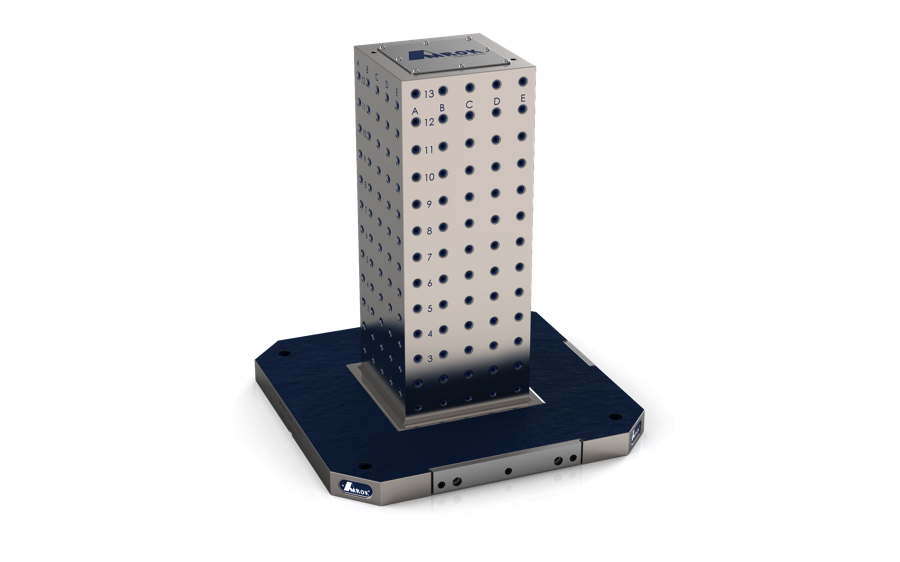

Grid

Plain Face

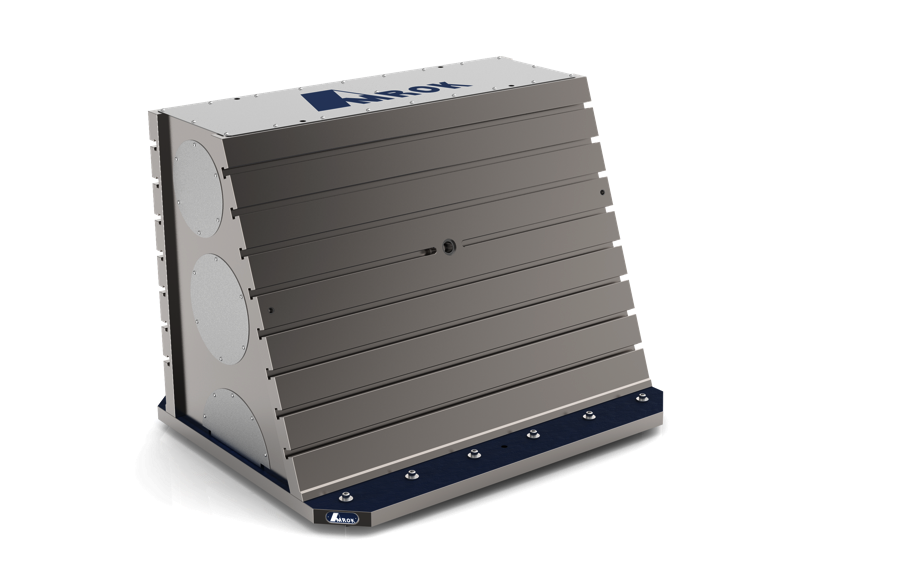

T-Slot

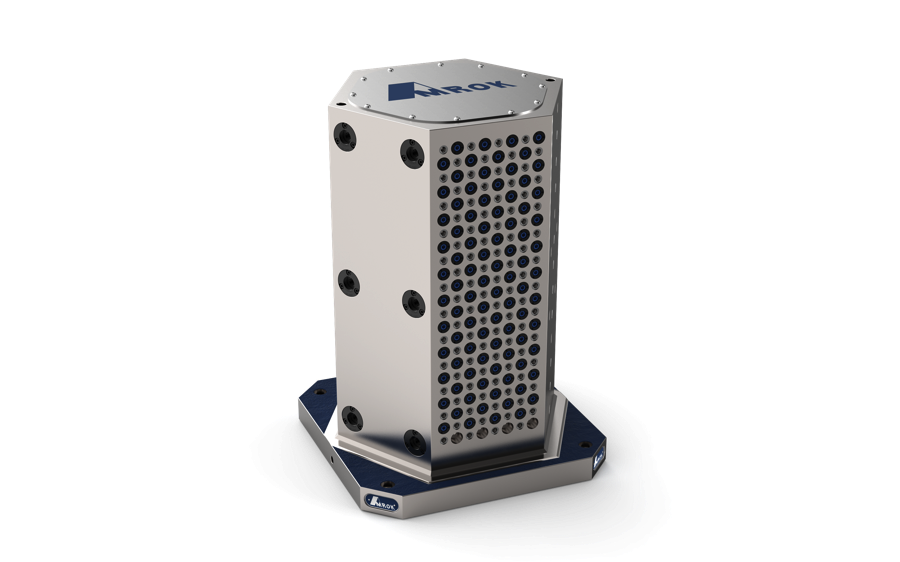

Custom

Tolerance & Machining Options

Grid

For maximum flexibility, choose a precision grid. AMROK® grids are typically machined to the industry standard 2-inch spacing, but custom spacing is available upon request. Alpha-numeric labeling makes it easy to relocate fixturing components on the grid. Each hole features a hardened threaded insert beneath a precision bushing and can be used for both locating and mounting.

View Details

Plain Face

For customers who prefer to machine the mounting and locating holes themselves, plain face AMROK® Tombstones are available with machined faces manufactured to precision tolerances for parallelism and perpendicularity within the tooling column.

View Details

Custom

Have a custom requirement? AMROK® tombstones can be customized to individual specifications.

View Details