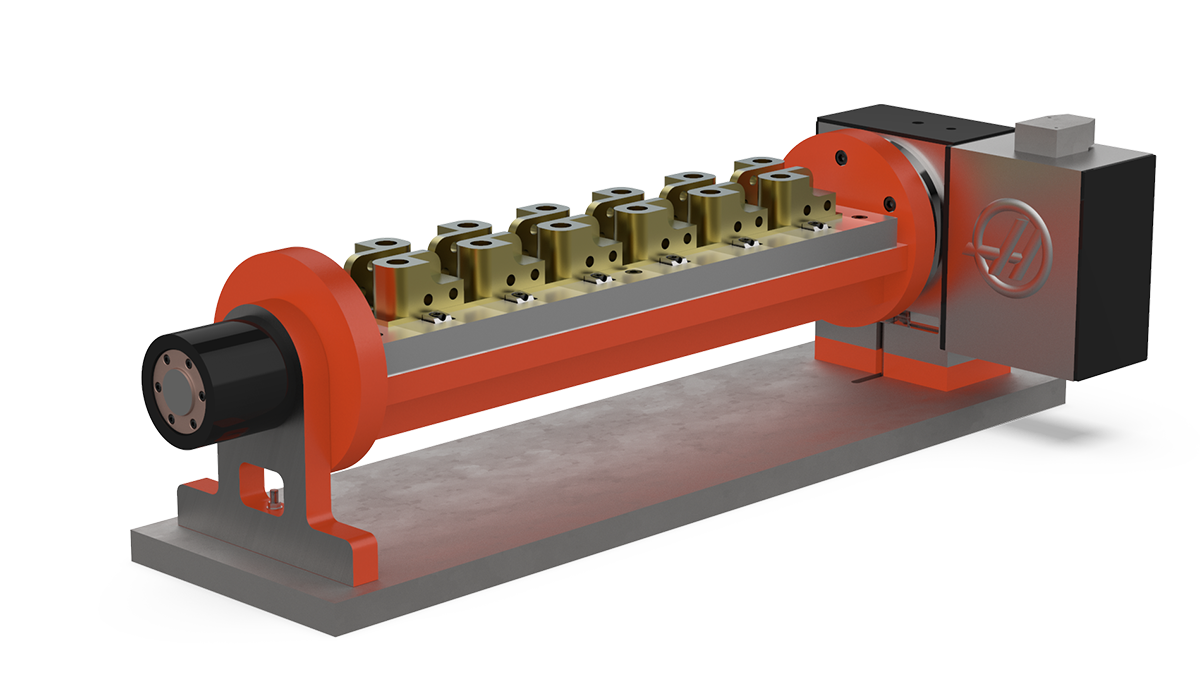

Powerful Workholding Fixtures in a Small Package

Mitee-Bite, the pioneer in compact and low-profile edge clamps, offers innovative solutions for challenging workholding applications, aimed at enhancing production efficiency. We take pride in delivering products that enable customers to streamline their processes through simple yet effective means. Our dedicated engineers are available to support you in designing and developing new procedures involving Mitee-Bite products. By reducing idle spindle time, minimizing wasted man-hours, and increasing overall efficiency and output, you can gain a competitive edge in the global marketplace.

Mitee-Bite Systems

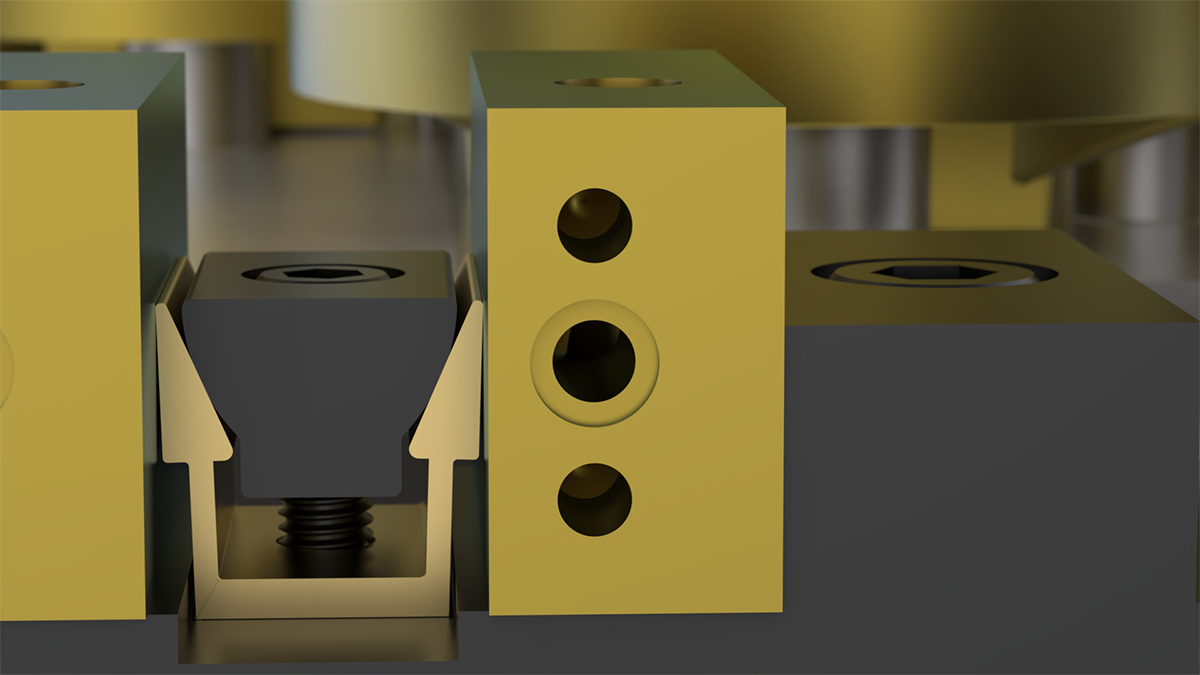

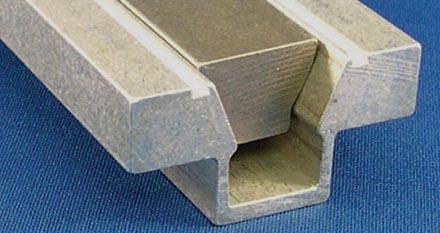

Uniforce Clamps

This compact, economical clamp enables you to fixture more parts on the machine table. The specially designed steel wedge spreads the clamping force uniformly on both sides of the 7075-T6 aluminum channel. Holds two parts with equilateral clamping action. Ideal for clamping flat or round work pieces

Explore Uniforce Clamps

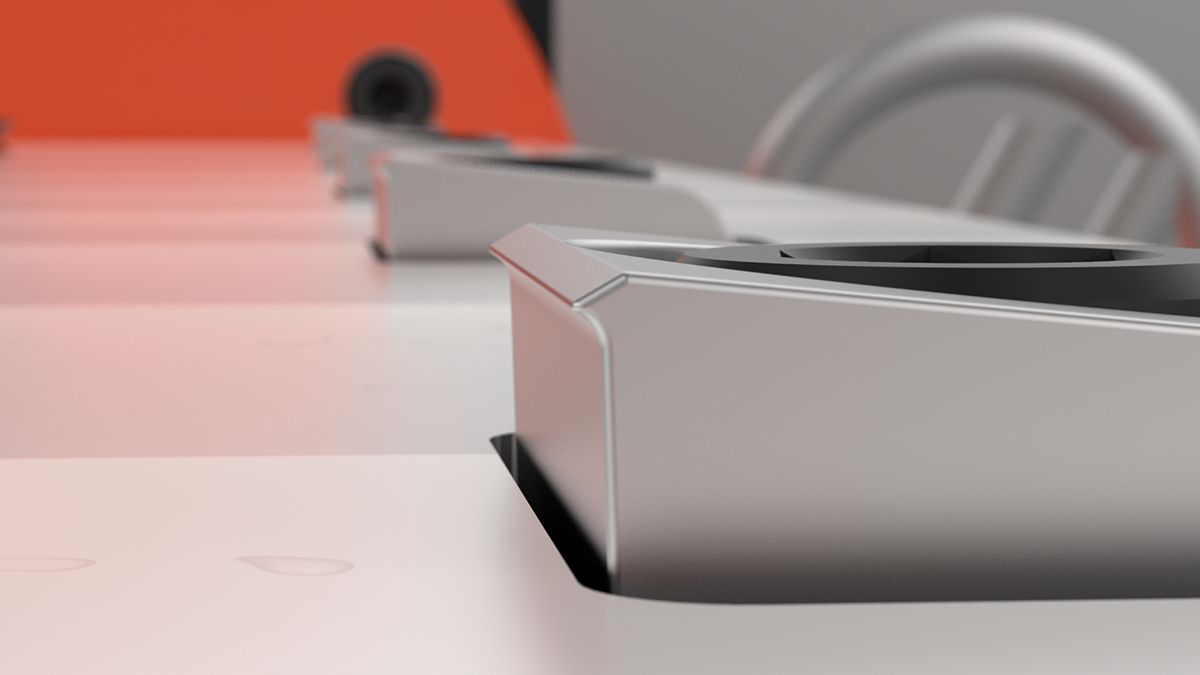

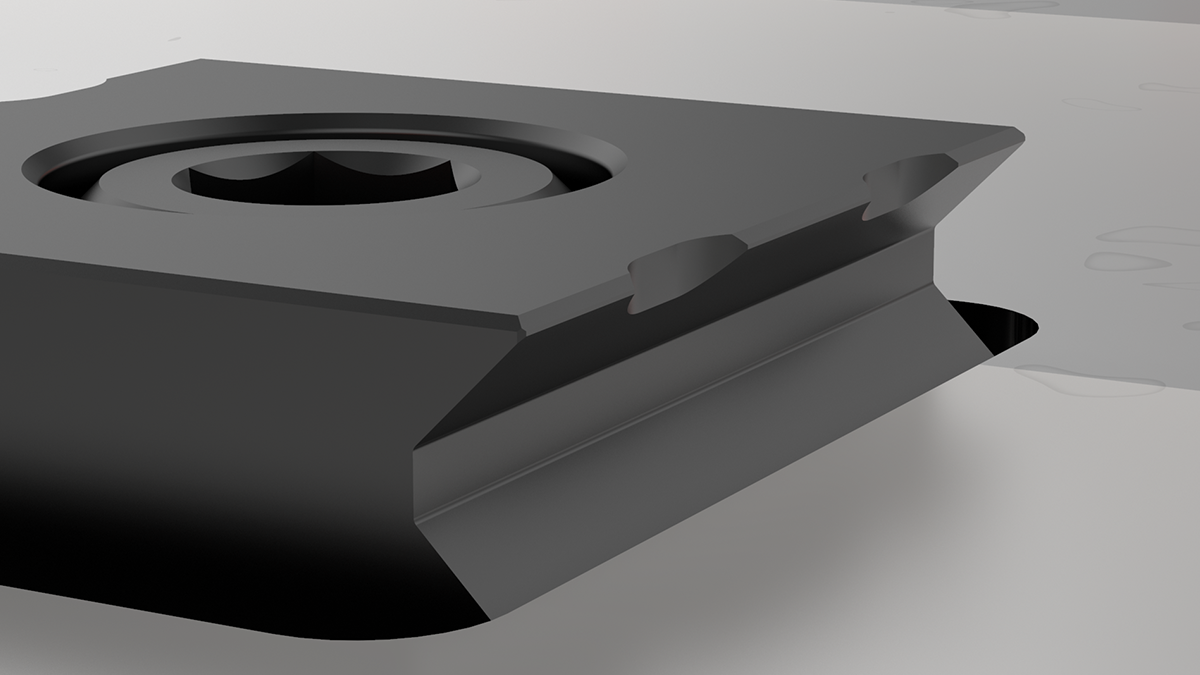

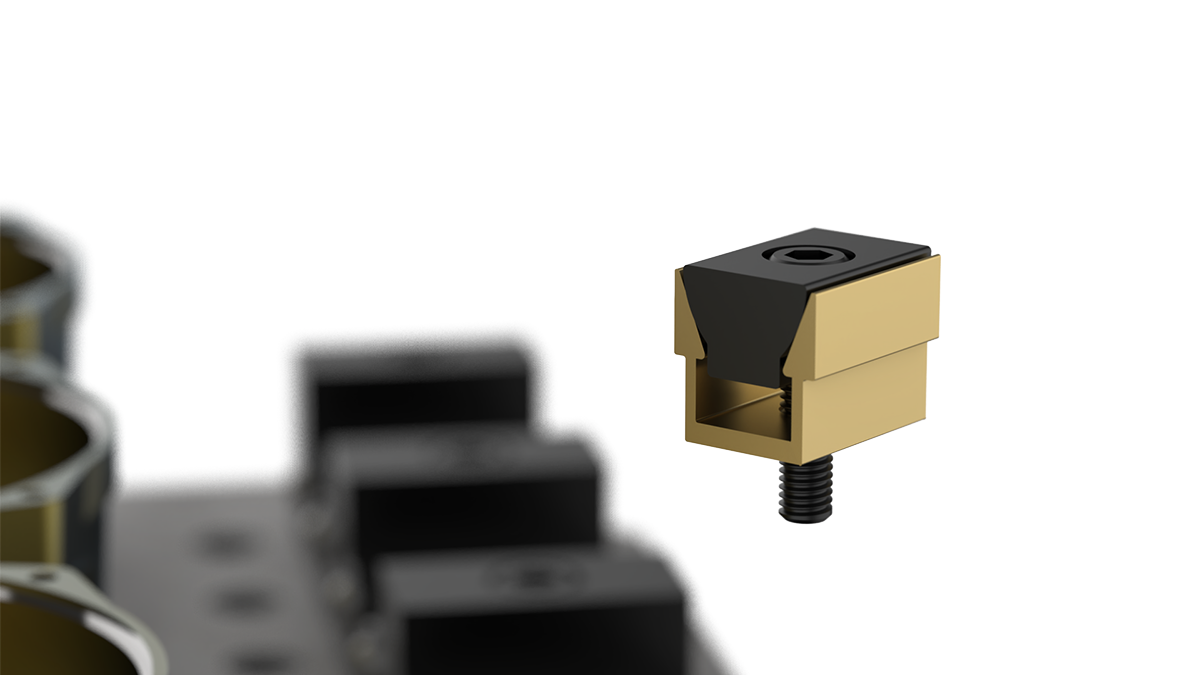

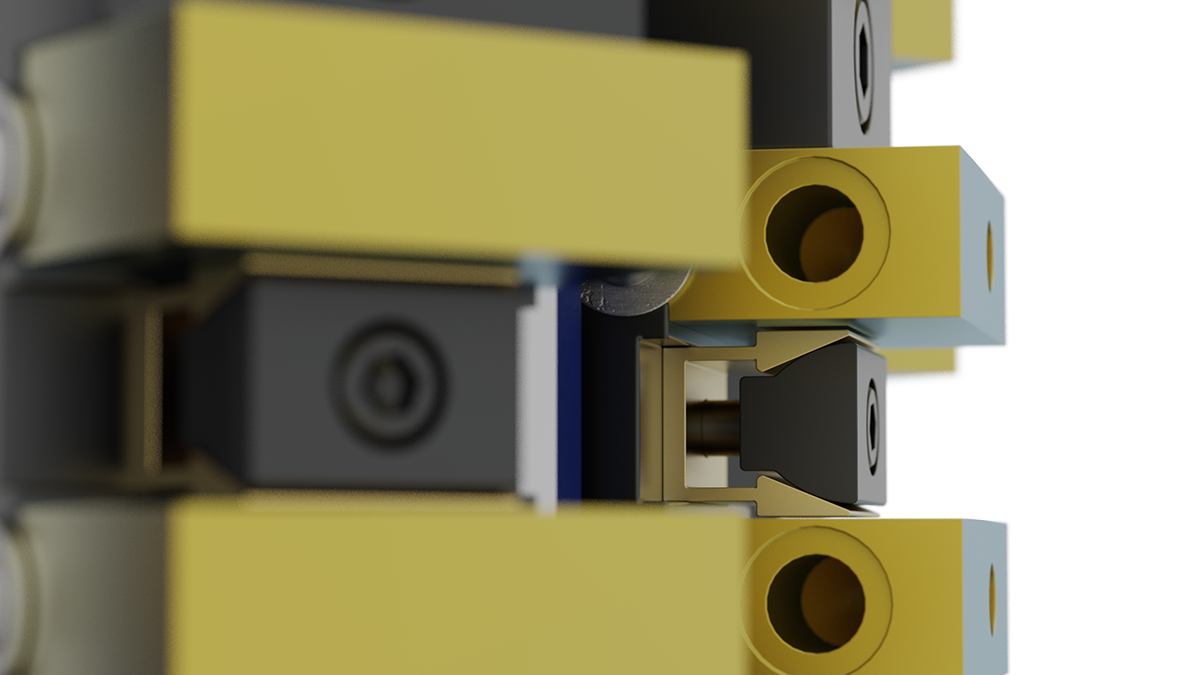

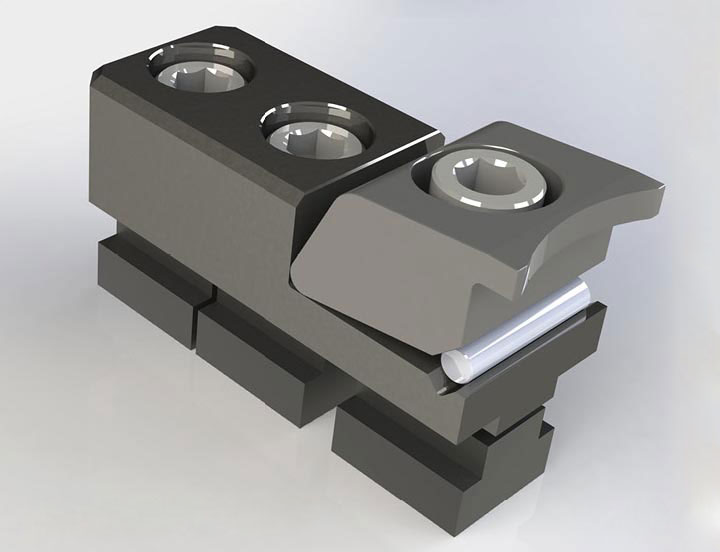

Pitbull Clamps

The lowest profile, highest holding force clamp in the industry today. Able to generate high vertical and horizontal clamping forces, despite their size. It uses a standard cap screw and an oil-resistant O-ring. Available in five sizes and several styles: a tool steel knife edge for aggressive stock removal, a tool steel blunt edge for general purpose, a brass version to help prevent marring the workpiece and a machinable version.

Explore Pitbull Clamps

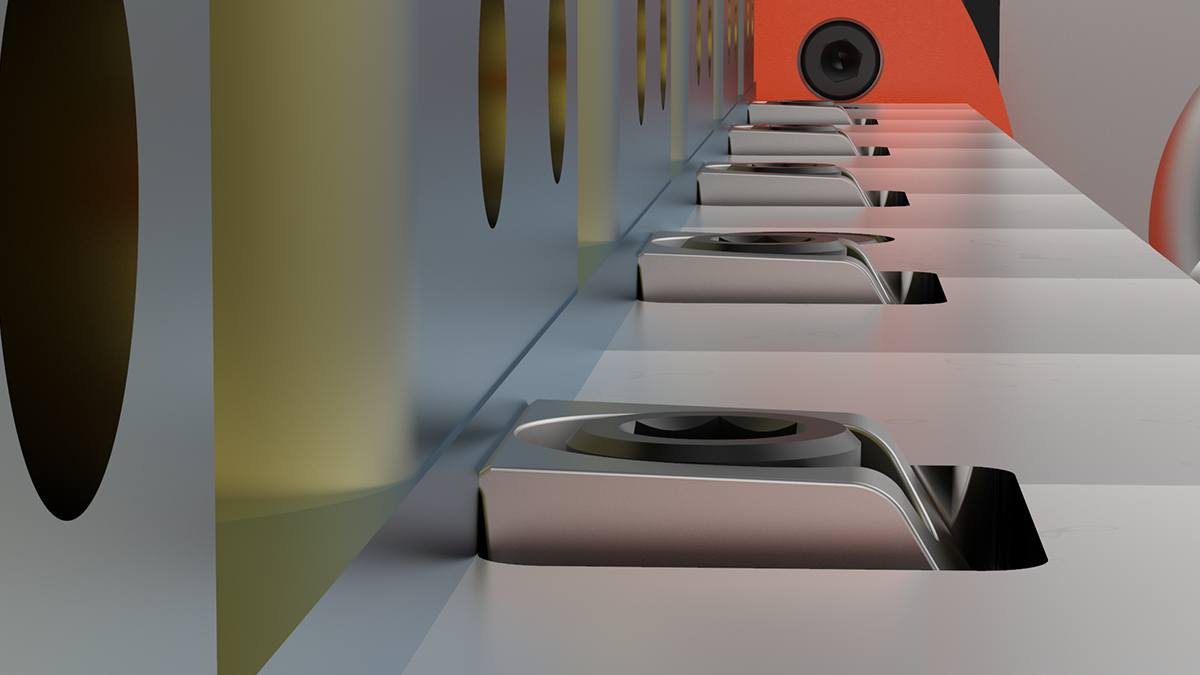

Dyna-Force Clamps

The majority of the clamp is below the surface of the fixture, providing excellent clamp support and an extremely low profile. The clamp jaw slides on an angle for positive downforce. Available with smooth or serrated faces. The support surface of the clamp can be installed flush with the fixture plate or raised to hold the workpiece off the fixture, enabling drill-through.

Explore Dyna-Force Clamps

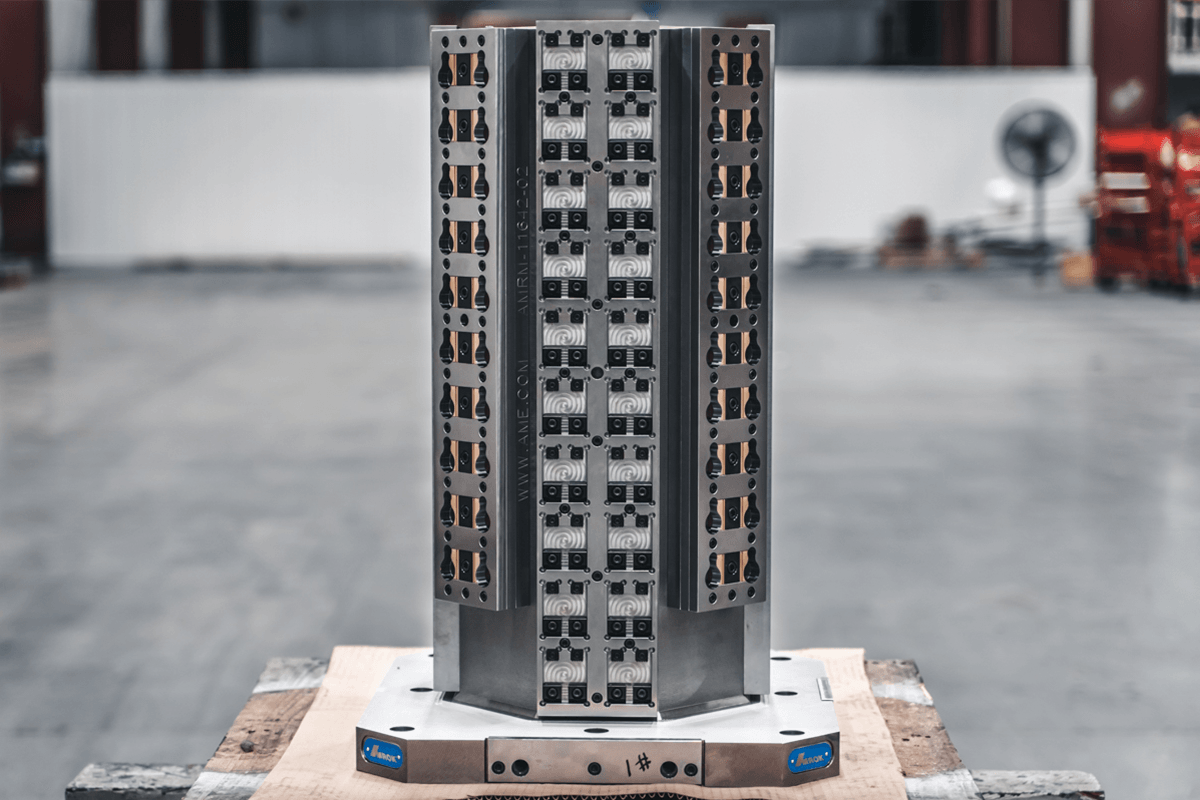

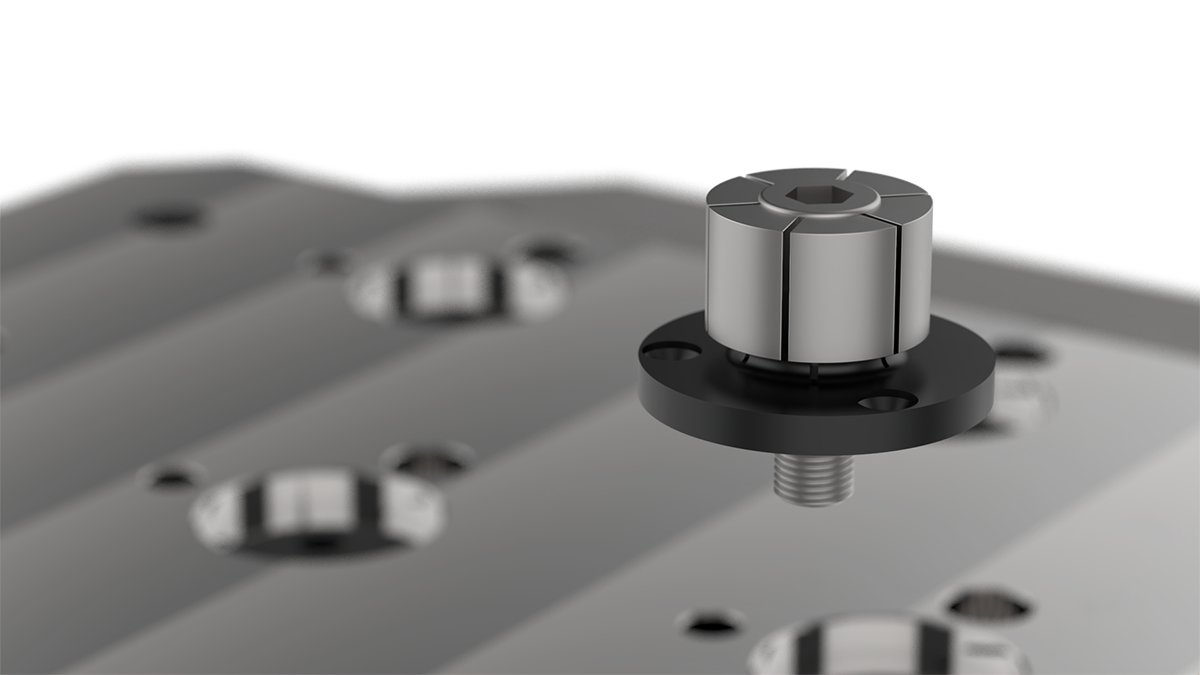

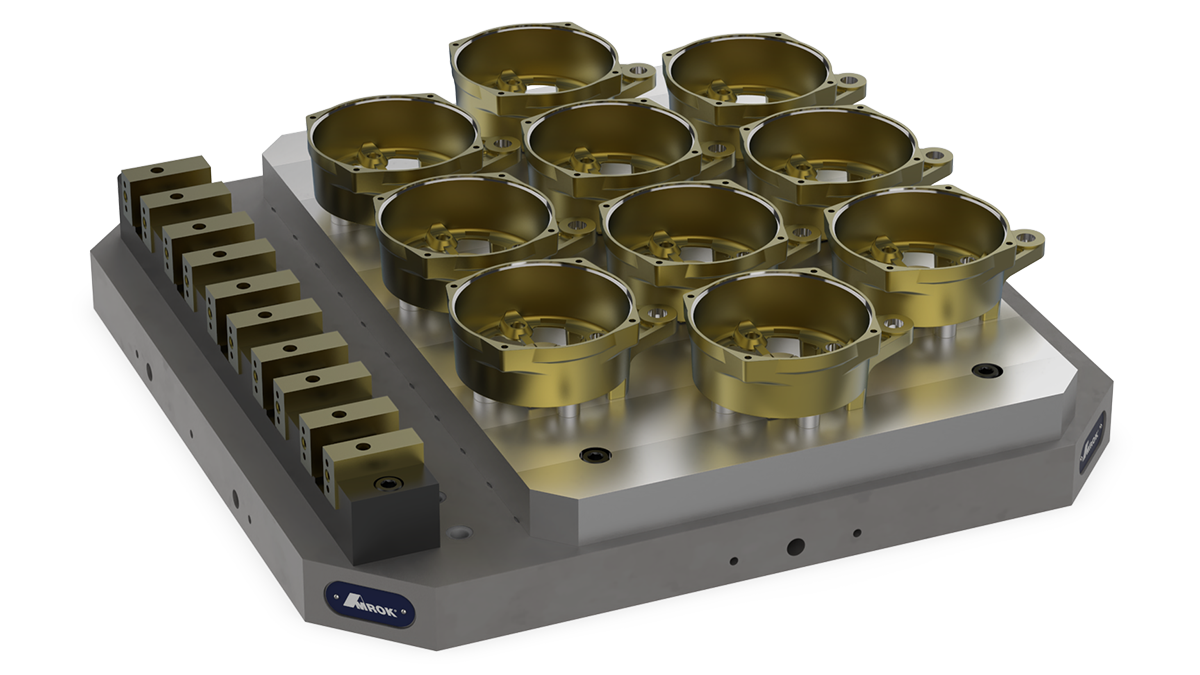

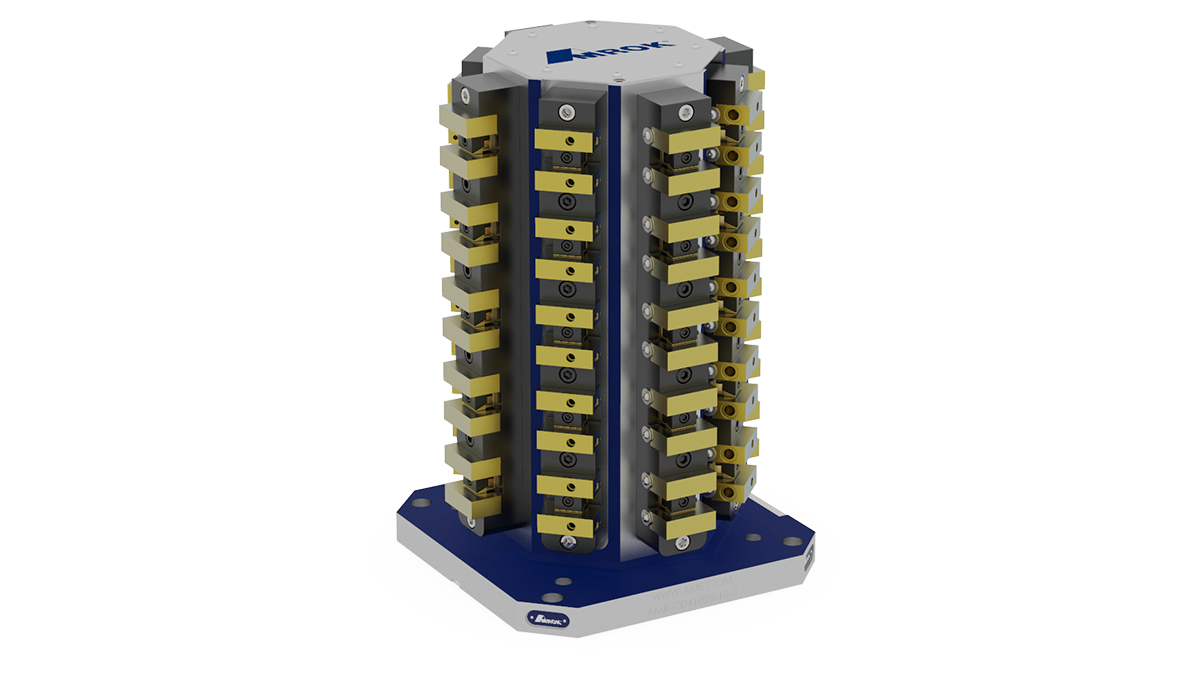

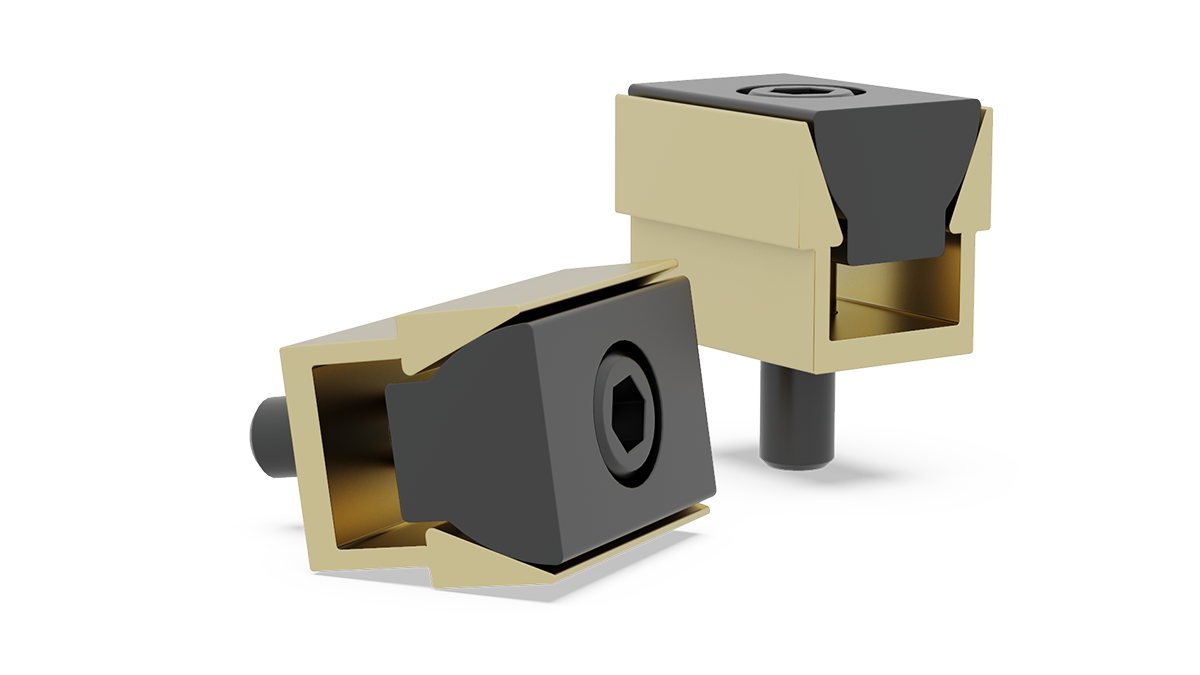

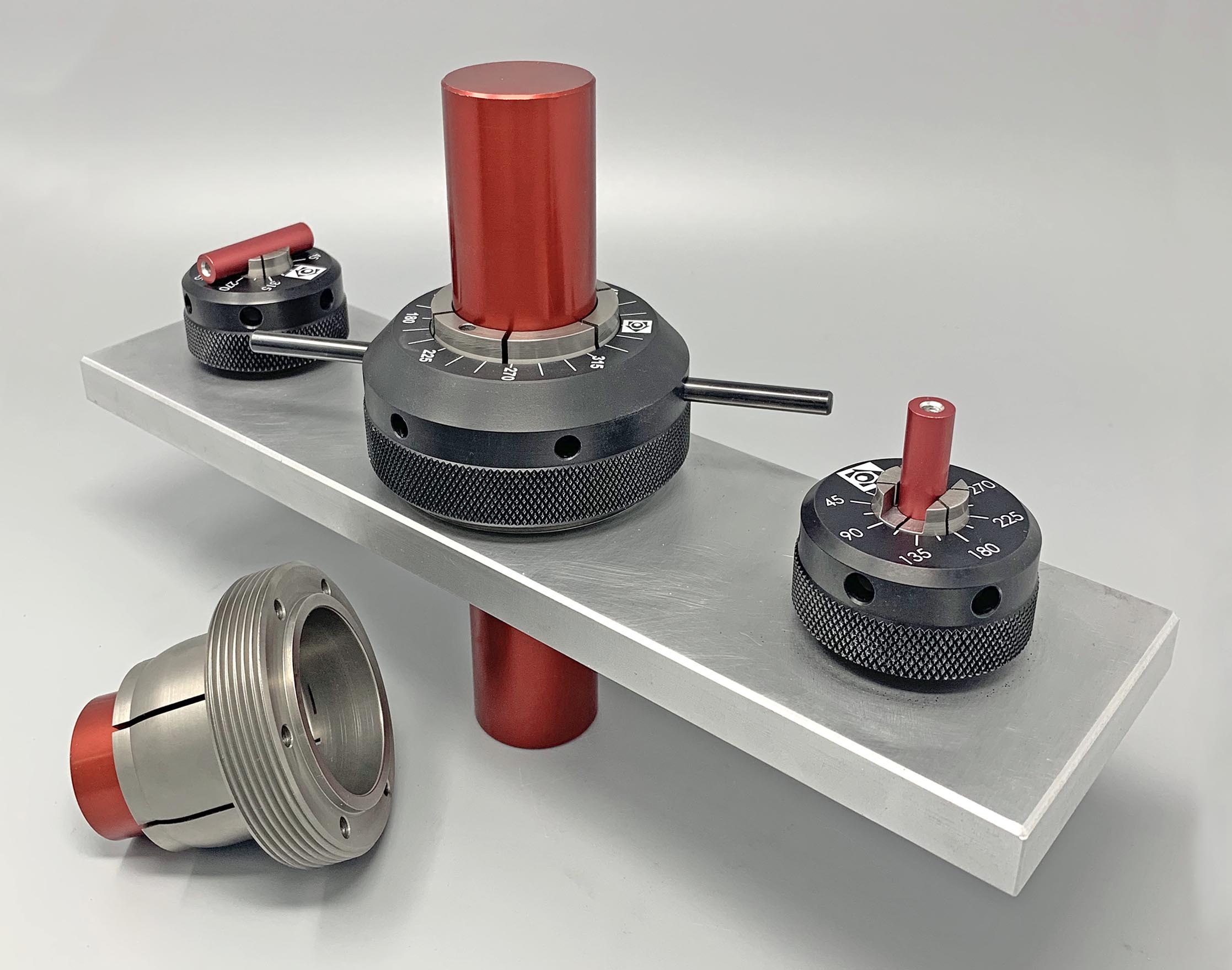

ID Xpansion Clamp

The ideal solution to hold parts on an inside diameter for high density machining on vertical or horizontal machining centers. It can also be used as an expanding mandrel on a lathe. These machinable clamps are produced in 12L14 steel with black oxide coating in 12 sizes and can hold internal diameters from under 3/16 to almost 10 inches (4.1 to 254mm). #10 manufactured using 7075-T6 aluminum. The flange diameter of the clamp is held to a close tolerance for precision locating in a machined pocket on work cubes and fixture plates. The customer machines the mild steel clamp to match the bore of the part ensuring a proper fit. Often times the clamps can be remachined for different size jobs. They are quickly tightened with a hex key, torque driver or can be mated to hydraulic pull cylinders for automation.

Explore ID Xpansion Clamps

Compact Toe Clamps

This cam action fixture clamp provides positive down force while using very little space on a fixture. Work pieces can be clamped in series by using the back surface of a clamp to locate the next work piece.

Explore Toe Clamps

Fixture Clamps

The Cam Action MITEE-BITE Fixture Clamp is made up of two simple components: a hardened steel socket cap screw with an offset head and a brass hexagonal washer.

Explore Fixture Clamps

Knife Edge Clamps

Knife Edge Clamps can be used instead of the original brass hex clamps for clamping rough cut stock, castings and any material that requires a hardened clamping element. Same "G" as original Fixture Clamp.

Explore Knife Clamps

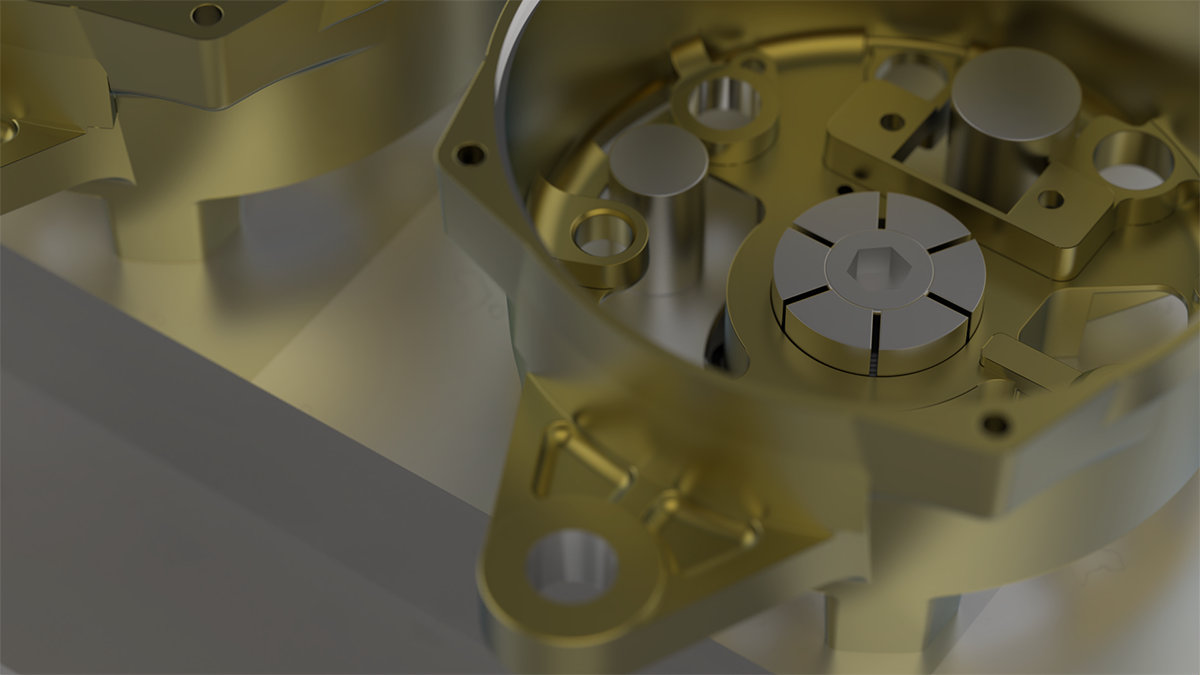

Concentric OD Clamps

Repeats within tenths, compact for high density application and tough enough to limit yourself to tooling capabilities. This Patent Pending design can be machined, to hold any shape, completely through clamp (“F” bottom chart) and fixture plate as well as gripping workpiece above compression nut. 15° incremental laser engraved indicators on large cap (22.5° on small cap) for applying repeatable torque without torque wrench and for applying preload (15° – 45°) when machining clamps to actual workpiece dimensions.

Explore Concentric OD Clamps

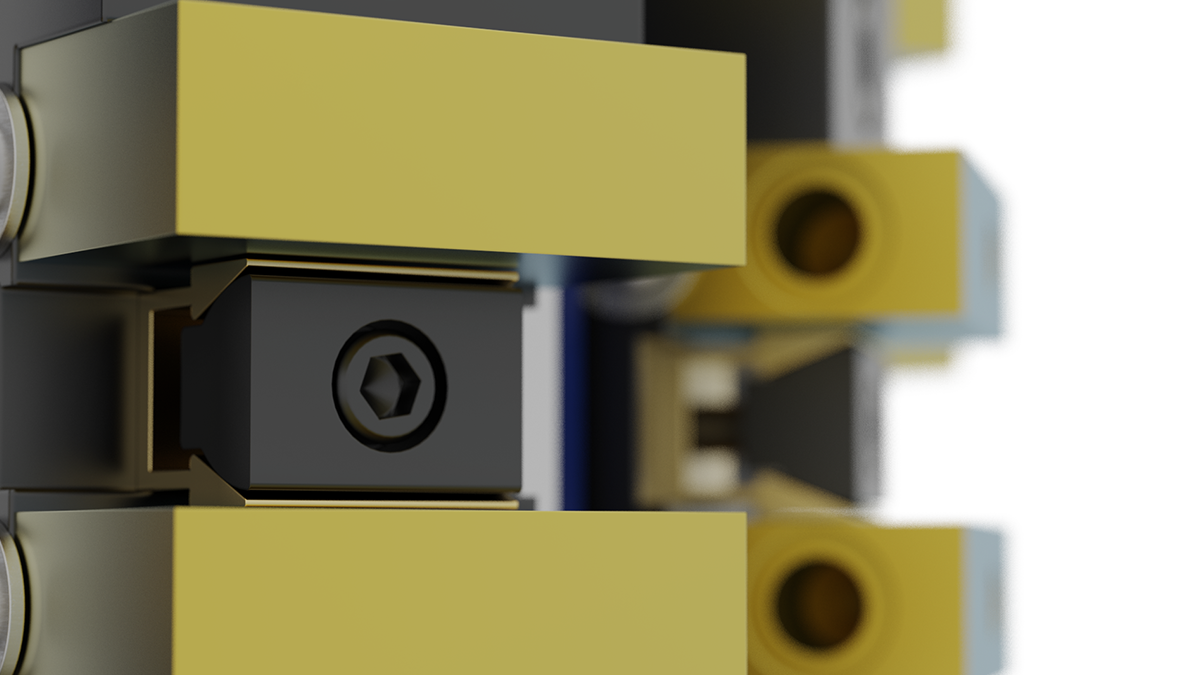

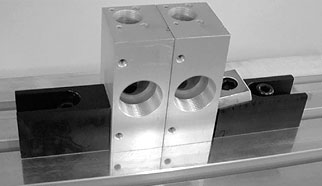

Heavy Duty T-Slot Clamps

Mitee-Bite Products introduces the Heavy Duty™ T-Slot Clamps – capable of generating over 20,000 pounds of pressure. This design utilizes some of the strongest lowest-profile clamps in the industry.

Explore Heavy Duty T-Slot Clamps

Long Length Machinable Uniforce® Clamps

Mitee-Bite products introduces the long length Uniforce® Clamp with machinable jaws. The long length clamping jaws give you greater versatility to machine the clamp to conform to the shape of your workpiece, enabling you to fixture difficult applications easily.

Explore Long Length Uniforce® Clamps

Long Length Channel (7075-T6) & Steel Wedge

This material is available in 20″ (508mm) lengths so clamps can be fabricated in different lengths to suit any requirement. Channel and steel wedge are not drilled or plated.

Explore Long Channel and Steel Wedge

Locating Rails

Mitee-Bite Products makes fixture building easier and quicker with the addition of ready-made locating rails. Rails are made of low carbon steel, then ground square. They are easily machined when used with our machinable clamps. Tungsten Carbide coating can be added to increase holding force.

Explore Locating Rails

Machinable Fixture Clamps

These clamps, with the machinable steel washers, provide more flexibility for holding round or unusual shaped parts. Parts can be held directly to the fixture plate surface or elevated for through-drilling.

Explore Machinable Fixture Clamps

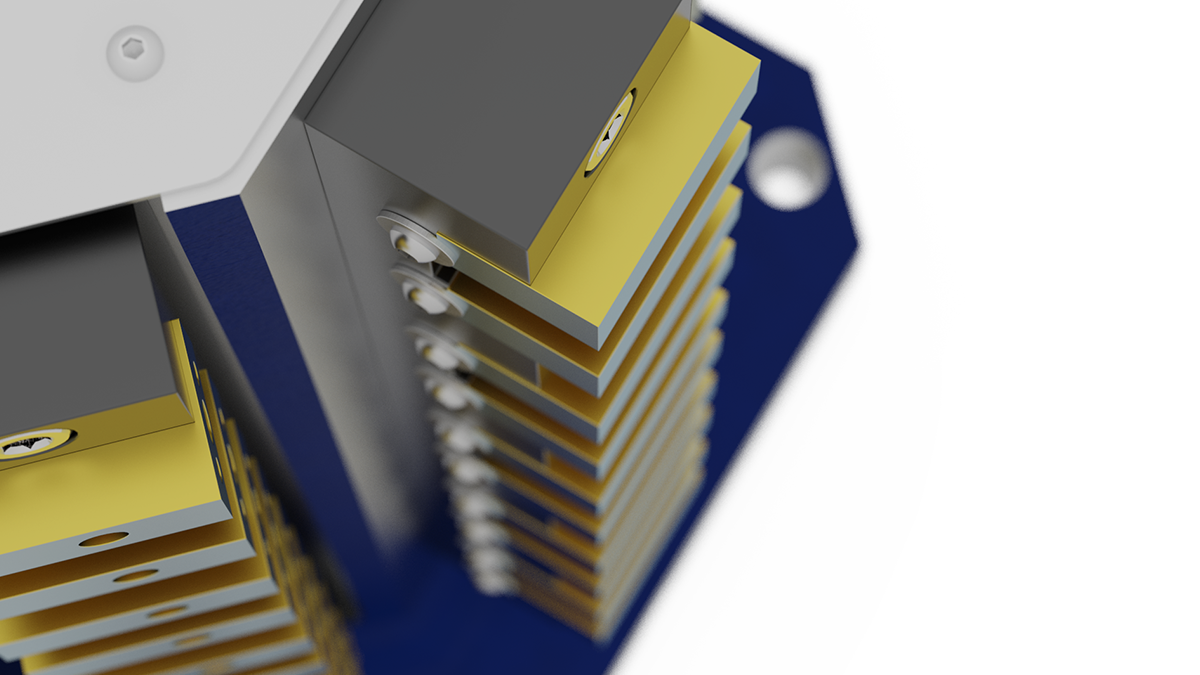

Multi-Fixture Clamps & Stops

The Mitee-Bite Multi-Fixture Clamp offers increased versatility through its unique riser clamp design.

Explore Multi-Fixture Clamps & Stops