MSU Sensor System

MSU SENSOR SYSTEM

SMART 3-IN-1 MONITORING SOLUTION

MSU is a sensor-based assistance system that is integrated into OTT-JAKOB unclamping units, helping to increase the availability and efficiency of a machine tool. The unique concept of MSU combines three monitoring functions in one unit:

- Identification of the drawbar shaft position

- Detection of the piston position

- Detection of leakage in the rotary union (optional)

Monitoring these parameters is essential to ensure a controlled production process. The measurement data is collected during machining so that information on the actual machine condition is obtained. These can be used as part of predictive maintenance for analysis and/or as a decision-making basis.

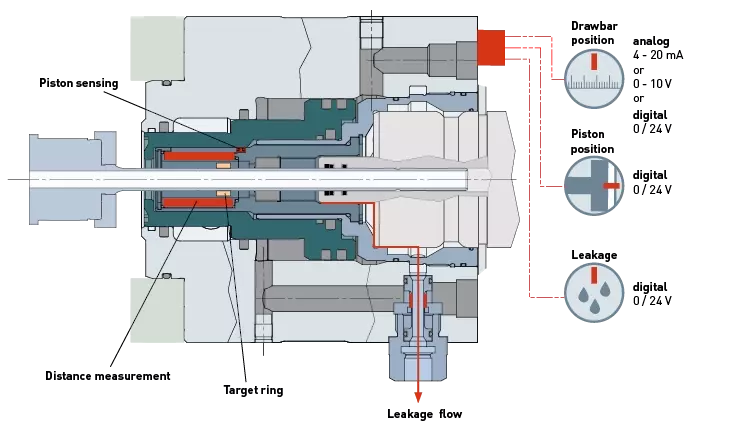

Safe clamping and unclamping process

The position of the drawbar shaft is monitored by an electronic distance measurement system. This detects the exact position of the drawbar shaft and thus the current tool position by means of a target ring on the drawbar shaft. The system recognises the three clamping statuses "Unclamped", "Tool clamped" and "Clamped without tool". This information prevents the tool changer from removing the tool from the spindle too early or from starting the spindle before the tool is (correctly) clamped.

Reduced waiting times

The integrated piston sensing monitors the position of the unclamping unit piston and ensures that it has no contact with rotating machine elements during machining. As soon as the piston has reached a safe end position, a digital signal is generated for the machine control. This signal ensures that the piston is in the "Tool clamped" mode and that the spindle is released without any time delay. In addition, piston sensing can be used to implement an energy-saving and modern hydraulic system.

Process-integrated leakage monitoring

Optionally, a sensor for measuring the leakage flow in rotary unions can be integrated into an MSU unclamping unit. As an early warning system, it triggers a signal when the predetermined flow limit is exceeded. This way, the spindle is effectively protected against flooding.