P-Series Billet Saw - Carbide Pivot Saw

COST EFFECTIVE PRODUCTION

With fewer moving parts and simple design, the P-Series billet saw is an economical solution requiring little maintenance. Its rigid design eliminates the need for expensive slides which require constant lubrication to avoid wear.

FEATURES

FEATURES

- Closed-loop force flow

- Low backlash gearbox

- Drive spindle mounted on heavy duty, pre-loaded bearings

- Heavy-duty fabricated base filled with vibration reducing compound to increase tool life

CUTTING CAPABILITIES

- Bars

- Billets

- Tubes & Pipes

- Rails

- Profiles

- Extrusions

- D-Bar

- Track Shoes

- And More

STANDARD P-SERIES AMSAW® MODELS (up to 350mm/14” stock size)

AMSAW P-SERIES SPECIFICATIONS

| SPECIFICATION | AMS 125 | AMS 180 | AMS 250 | AMS 350 | |

|---|---|---|---|---|---|

| Cutting Capacity | Round & Square Stock - mm (") | 25 (1.0) - 125 (5.0) | 38 (1.5) - 180 (7.0) | 75 (3.0) - 270 (10.75) | 125 (5.0) - 355 (14) |

| Stock Bar Length Max. - m (ft.) | 6.0 (20) | 6.0 (20) | 6.0 (20) | 6.0 (20) | |

| Cutoff Length - mm (") | 8 (0.3) - 1000 (39.4) | 8 (0.3) - 1000 (39.4) | 16 (.75) - 760 (30) | 16 (.75) - 760 (30) | |

| Remnant End Length - mm (") | 16 (.75) | 25 (1.0) | 38 (1.5) | 38 (1.5) | |

| Circular Saw Blade | Min. blade diameter - mm (") | 280 (11) | 360 (14) | 610 (24) | 660 (26) |

| Carbide/Cermet Tipped | Max. blade diameter - mm (") | 406 (16) | 600 (23.6) | 990 (39) | 1120 (44) |

| Blade pilot diameter - mm (") | 50 (1.969) | 80 (3.150) | 100 (3.936) | 100 (3.936) | |

| (2) Drive pins diameter - mm (") | 16 (0.629) | 18 (0.709) | 30 (1.181) | 30 (1.181) | |

| Drive pins placement diameter - mm (") | 80 (3.149) | 120 (4.724) | 200 (7.873) | 200 (7.873) | |

| Cutting Information | RPM variable by inverter (1/min) | 69 - 209 | 33 - 99 | 29 - 88 | 24 - 70 |

| Feed rate by servo driven ball screw** mm/min ("/min) |

0 - 2000 (0 - 80) | 0 - 1800 (0 - 70) | 0 - 750 (0 - 30) | 0 - 600 (0 - 25) | |

| Bar Feed (Indexing) | Max feed rate forward - m/min ("/min) | 30 (1200) | 20 (800) | 15 (600) | 15 (600) |

| Repeatability - mm (") | 0.05 (0.002) | 0.05 (0.002) | 0.07 (0.003) | 0.07 (0.003) | |

| Opt. min. coolant | Micromist tank capacity - liter (oz) | 0.23 (8) | 0.23 (8) | 0.23 (8) | 0.23 (8) |

| Saw Motor | kW / HP | 15 / 20 | 30 / 40 | 45 / 60 | 55 / 75 |

| Hydraulics | kW / HP / bar (PSI) | 3.7 / 5 / 103 (1500) | 3.7 / 5 / 103 (1500) | 7.5 / 10 / 103 (1500) | 7.5 / 10 / 103 (1500) |

| Tank capacity - liter (gal) | 80 (20) | 150 (40) | 150 (40) | 150 (40) | |

| Electricals | Power Supply - V / Phase / Hz (USA) | 480 / 3 / 60 | 480 / 3 / 60 | 480 / 3 / 60 | 480 / 3 / 60 |

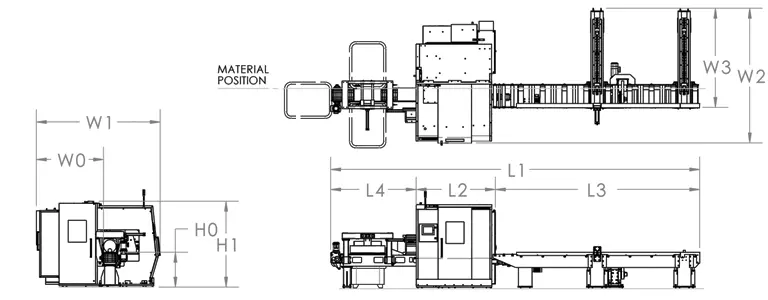

| Floor Space Machine | Feed roller height H0 - m (ft) | 1.0 (3.3) | 1.0 (3.3) | 1.0 (3.3) | 1.0 (3.3) |

| Machine height H1 - m (ft) | 2 (6.6) | 2 (6.6) | 2.4 (7.9) | 2.4 (7.9) | |

| Total length L1 - m (ft) | 8.5 (28.9) | 9.4 (30.8) | 10.3 (33.8) | 10.3 (33.8) | |

| Machine length L2 - m (ft) | 1.7 (5.6) | 2 (6) | 2.2 (7.2) | 2.2 (7.2) | |

| Load table length L3 - m (ft) | 4 (13) | 4.6 (15) | 5.7 (18.7) | 5.7 (18.7) | |

| Exit conveyor length L4 - m (ft) | 2.8 (9.2) | 2.8 (9.2) | 2.4 (7.9) | 2.4 (7.9) | |

| Material position W0 - m (ft) | 1.2 (3.9) | 1.3 (4.3) | 1.8 (5.9) | 1.8 (5.9) | |

| Machine width W1 - m (ft) | 1.4 (4.5) | 2.1 (6.9) | 3.5 (11.4) | 3.5 (11.4) | |

| Total width W2 - m (ft) | 1 (3.3) | 3.4 (11.2) | 3.8 (12.4) | 3.8 (12.4) | |

| Load table width W3 - m (ft) | 2.1 (6.8) | 2.5 (8.2) | 3.3 (10.8) | 3.3 (10.8) | |

| Weight (Approx) | Machine - kg (lbs) | 3173 (7000) | 4909 (10800) | 7364 (16200) | 9227 (20300) |

| Load Table - kg (lbs) | 845 (1860) | 1661 (3660) | 3173 (7000) | 3173 (7000) | |

| Accessories | Standard PLC control system, Touch screen HMI, Servo Motor & Ball Screw for Indexing and for Saw head feeding, Variable Blade-Speed by Inverter, Blade Cleaning Wire Brush, Blade Stabilizer 180 Degrees and 90 Degrees, Auto Lubrication System, Hydraulic Clamping arrangement, Multi-Indexing | ||||

| Options | Front blade stabilizer, material size verification, lift roller, bent bar mechanism, load table, chip conveyor, exit conveyor, pick and place assembly, mist collector | ||||

| *For larger, heavier slide saws see our AMSAW® 350/450/600 S-series brochure **Cutting feed rate depending on material specification Custom saw blade mounting also available per customer request | |||||

![]() Amsaw P-Series Brochure (English)

Amsaw P-Series Brochure (English)

![]() Amsaw P-Series Brochure (Chinese)

Amsaw P-Series Brochure (Chinese)

![]() Amsaw P-Series Brochure (German)

Amsaw P-Series Brochure (German)

![]() Amsaw P-Series Brochure (Polish)

Amsaw P-Series Brochure (Polish)