all (30) maximizing uptime (17) optimizing tool life (13) choosing a sawing machine (11) costs & benefits (10) sawing different materials (8) automating a process (6) FAQ (4) other (2)

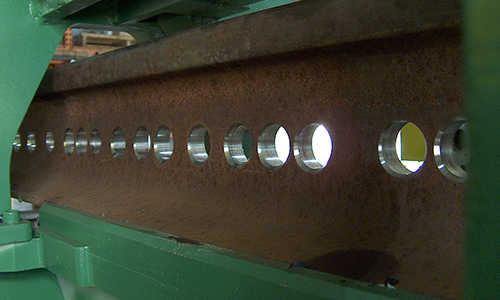

High Production Layer Saws for cutting Multiple Tubes or Bars

By cutting multiple bars or tubes in layers to increase productivity

- Read More | Comments (0) | Oct 16, 2020

Reading Chips Part 2

When operating a high production circular carbide saw quite a bit of process information from the cut chips on the shop floor can be gathered.

- Read More | Comments (0) | Apr 21, 2020

4 Ways to Reduce Vibration in Carbide Saws

Here are four ways to help reduce the damaging effects of vibration in your sawing processes.

- Read More | Comments (0) | Feb 07, 2019

When to Use a Slide Saw vs. a Pivot Saw?

Your floor space and layout, budget, and customer needs will determine if a carbide slide saw or carbide pivot saw is best for your machine shop operations.

- Read More | Comments (0) | Dec 03, 2018

Selecting the Right Material Handling System for Your Industrial Sawing Process

Investing in the right material handling system for your sawing application can improve safety and productivity of your overall sawing processes.

- Read More | Comments (1) | Nov 25, 2018

Infographic: Rail Fabrication Process with Rail Sawing and Drilling

The manufacturing process for rail production involves several steps to ensure the rail's durability and resistance to cracking.

- Read More | Comments (0) | Aug 15, 2018

Automating Manufacturing with Rail Sawing and Drilling Processes

Posted by Chris Rindels

Combination machines with material handling streamlines rail sawing and drilling processes -- providing more throughput, increased quality and efficiency, and improved viability.

- Read More | Comments (0) | Apr 06, 2018

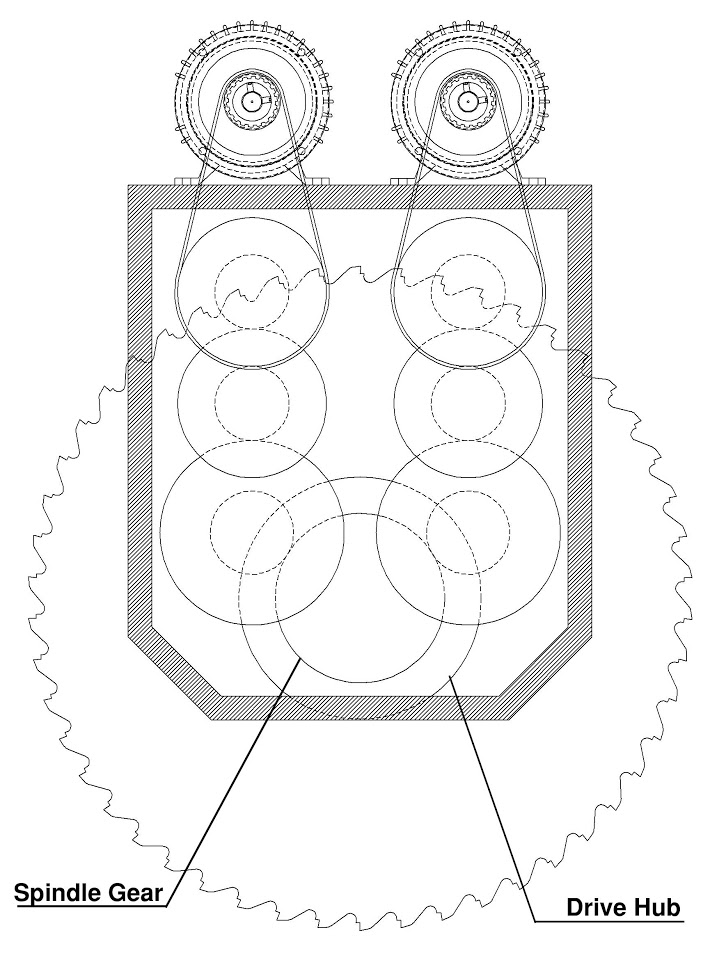

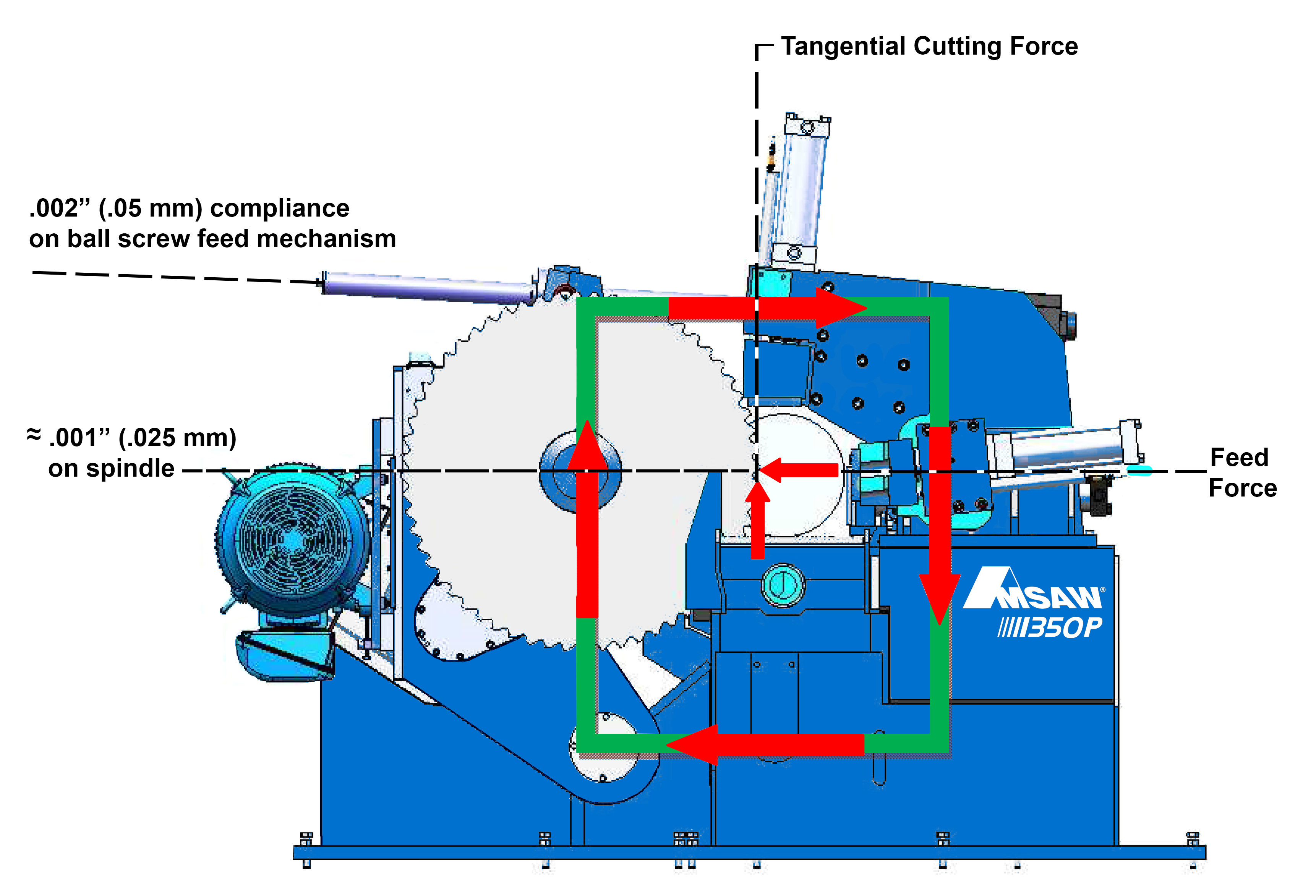

What Circular Saw Blade Tooth Geometry is Best for Sawing Steel Billets?

The heat from the cutting process, especially using negative cutting angles when cutting steel, transfers to the chip, causing it to expand and jam in the slot. This can be prevented by splitting the chip. There are two common tooth geometries developed to split the chip: “Triple Chip” and “Notch Grind.”

- Read More | Comments (0) | Dec 20, 2017