THE WRONG CLAMPING SYSTEM COULD BE HURTING YOUR SHOP’S PRODUCTIVITY

The journey to high-quality parts starts at your machine. What does the wrong clamping system look like?

- ▶ Excessive clamping forces causing dents after milling

- ▶ Varying surface finishes from chatter/vibration

- ▶ Burns on your surface part from overheating

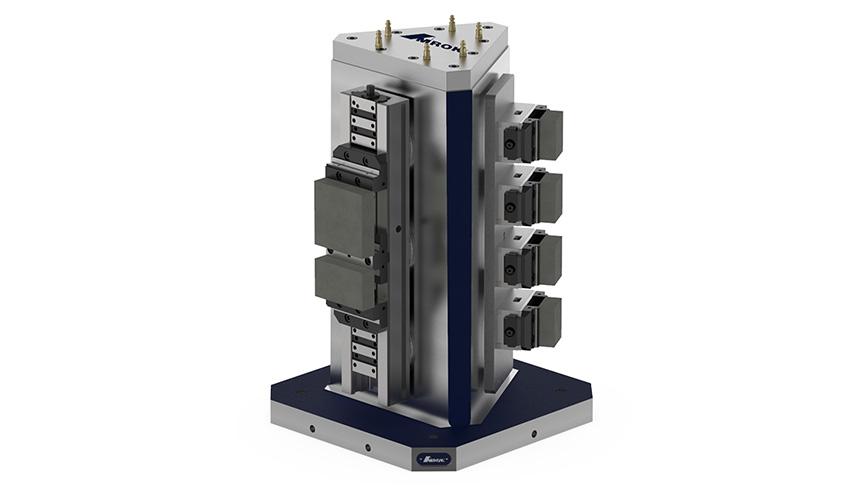

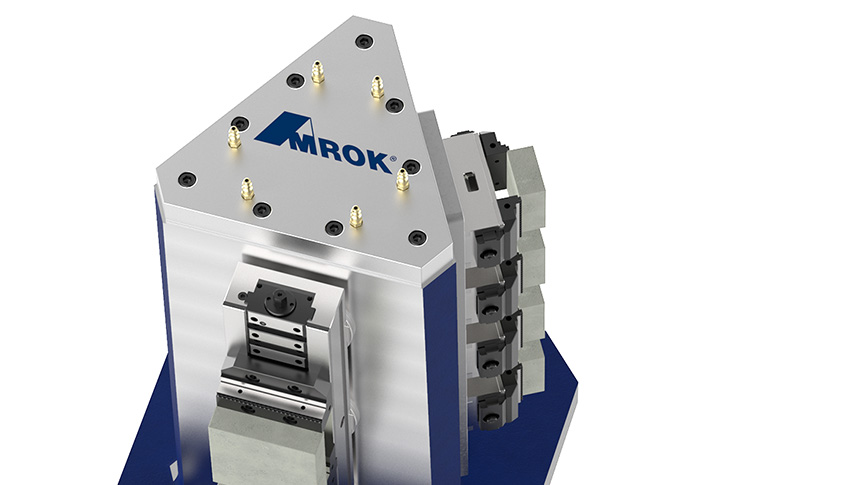

High-precision toolholding and modular workholding systems

BEST OF THE BEST, NO QUESTIONS ASKED

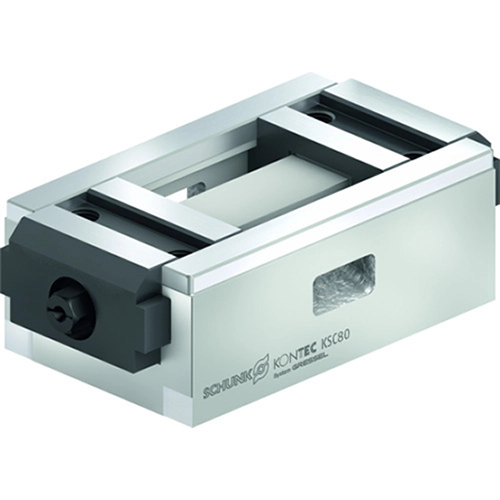

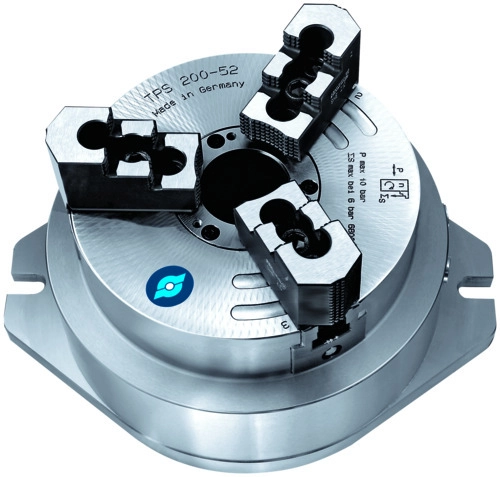

WORLD'S LARGEST LINE

SCHUNK offers the world's largest product line of gripping systems and clamping technology from a single source, boasting over 11,000 standard components.

SCALEBLE SOLUTIONS

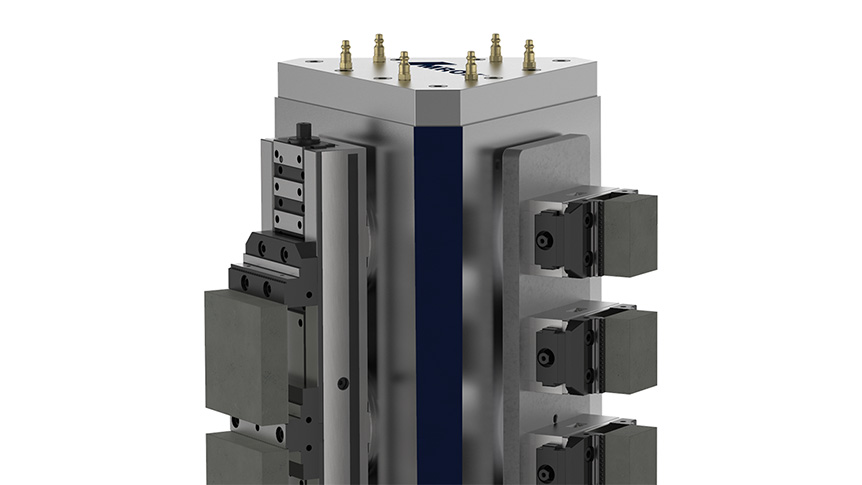

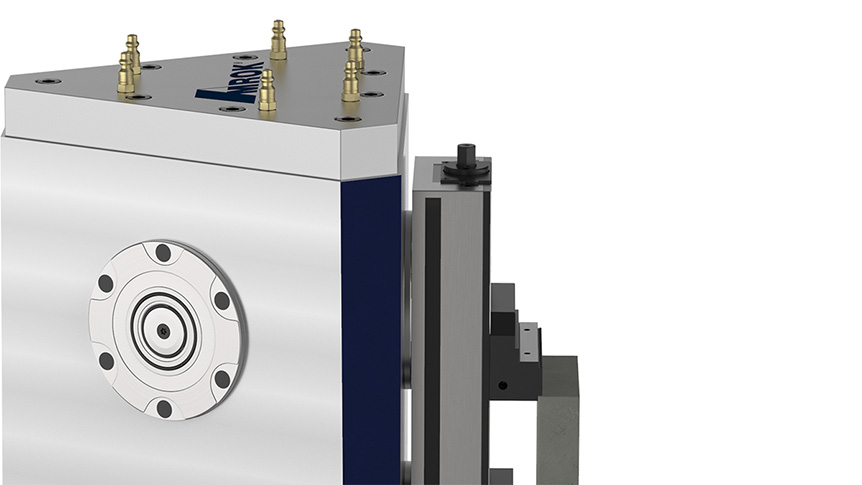

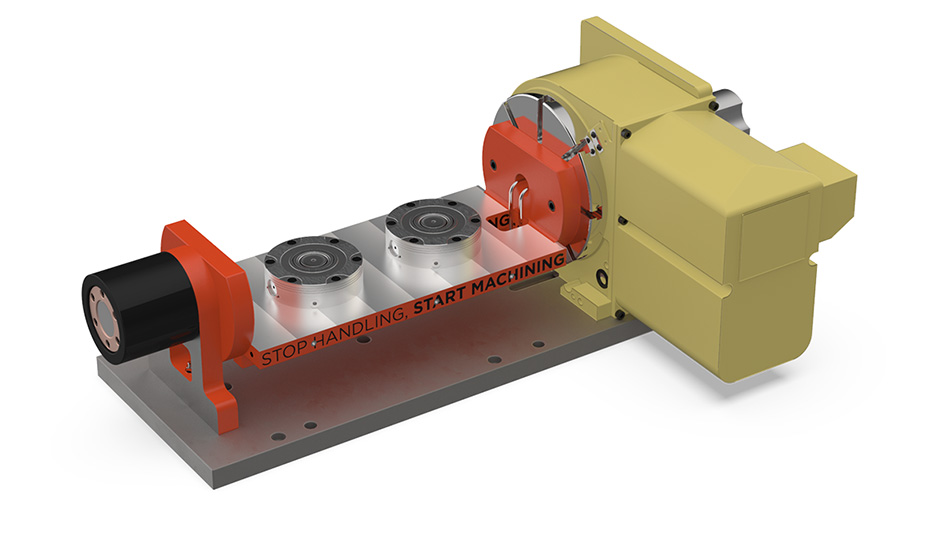

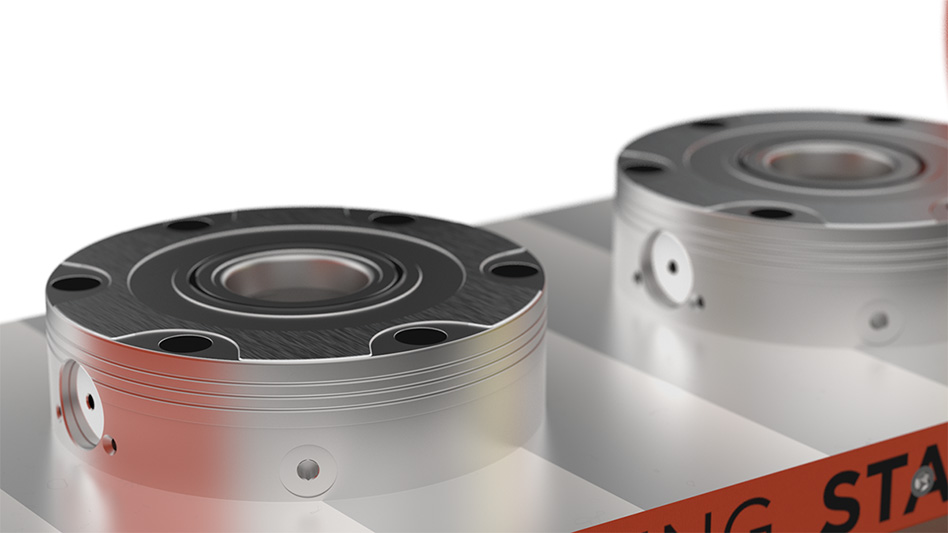

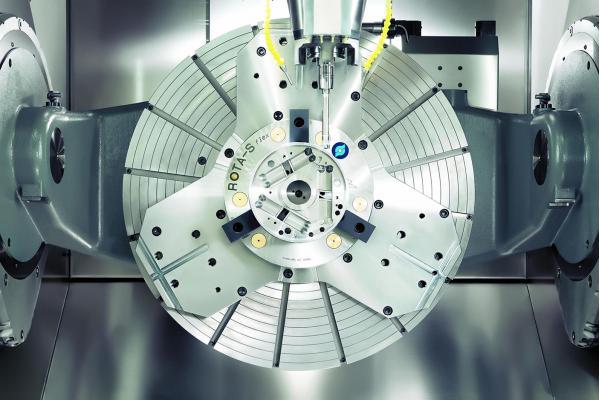

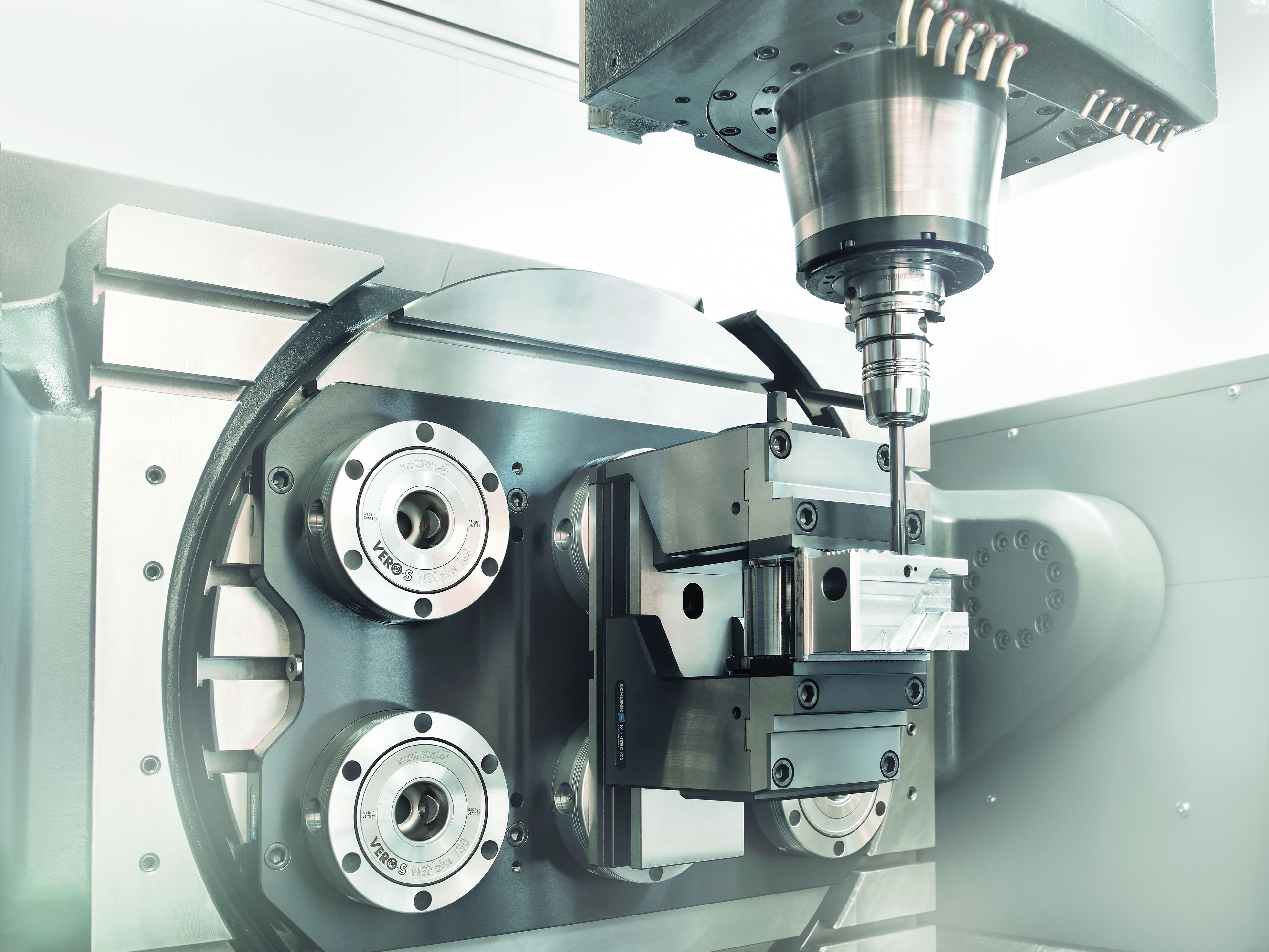

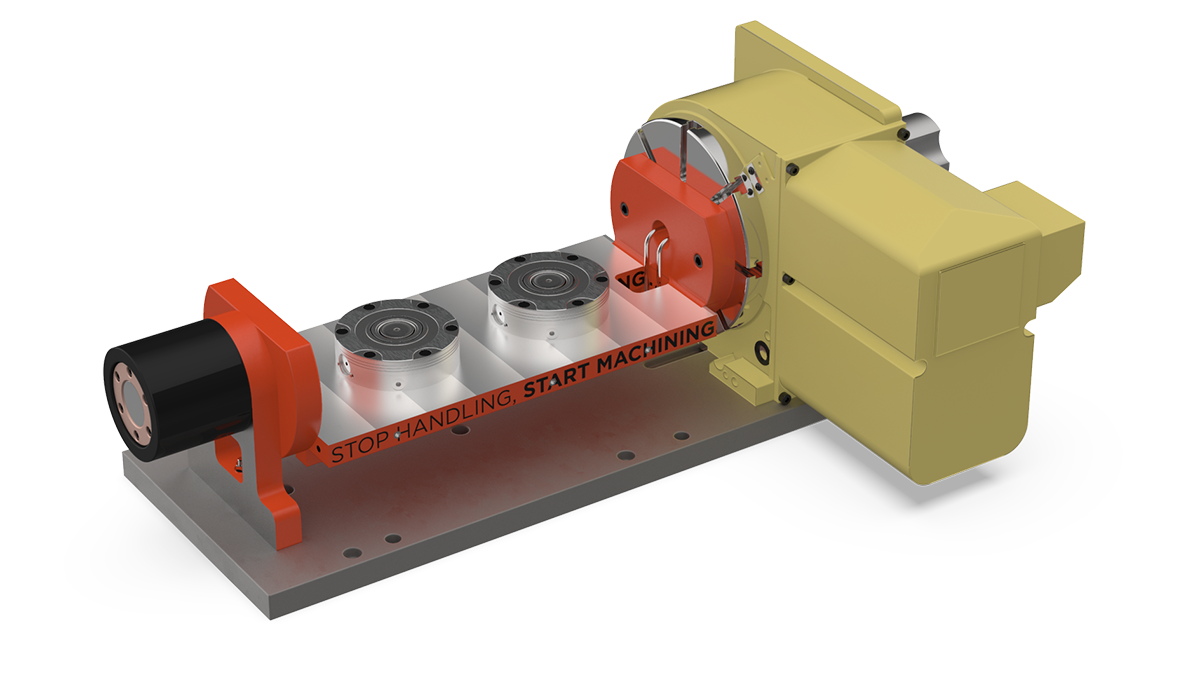

TExperience significant time savings with the VERO-S quick-change pallet system by reducing your set-up times by up to 90 percent. This versatile system enables quick and efficient changes of workpieces, pallets, clamping stations, and tombstones.

IMPROVED EFFICIENCY

Enhance production efficiency and flexibility with SCHUNK's clamping technology components, offering extremely short set-up times and high flexibility.

Endless workholding options can be overwhelming

That's why we take the guesswork out of workholding. Our staff specializes in turnkey integrations working engineer-to-engineer with our workholding partners so you can:

▶ Maximize throughput

▶ Minimize set ups

▶ Scale your operations.

FIND YOUR PERFECT WORKHOLDING SOLUTION TODAY

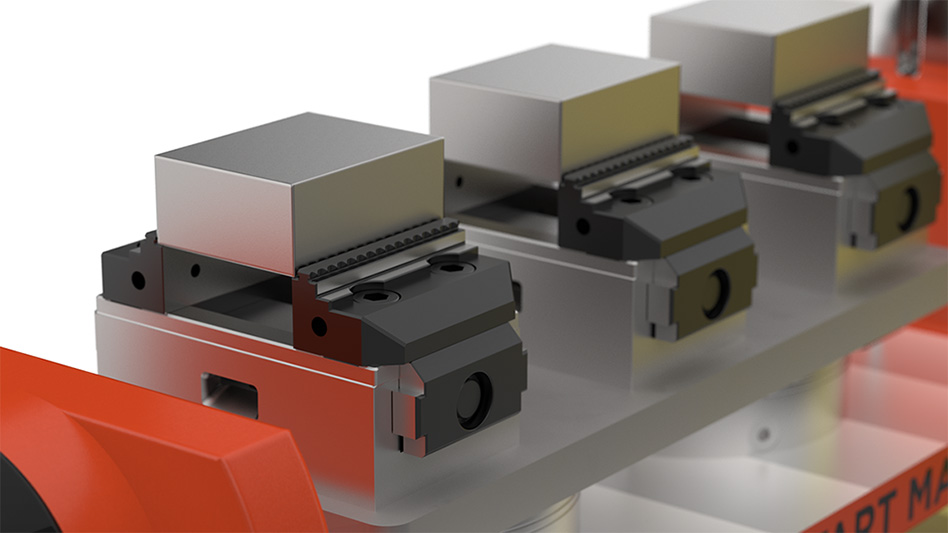

Vero-S

Modular quick-change pallet system for very fast and extremely precise conversion of workpieces, clamping devices or other equipment on modern machining centers. VERO-S can be almost limitlessly combined with other products and systems from SCHUNK's range of stationary workholding. This modular system offers more than 1,000 workpiece clamping variants. For your individual application.