Finding the Right Tombstone is Easy with AME

Posted by Levi Johnston

AME provides a handy guide on how to select the right tombstone from their wide range of products.

- Read More | Comments (0) | Jun 22, 2023

Okuma’s Partners in THINC Spotlights AME Workholding and Automation Expertise

Posted by Levi Johnston

AME is part of Okuma America’s Partners in THINC network, enhancing productivity, driving innovation, and bringing vast workholding and automation knowledge to end-users.

- Read More | Comments (0) | Apr 27, 2023

Overview of Workholding System Components - Part 2

Posted by Dr. John Ziegert, Ph.D.

The one component that is common to all workholding systems is a method for clamping the part(s). As we discussed earlier, machining involves forces that can be significantly high, and a clamping system is needed to restrain...

- Read More | Comments (0) | Nov 15, 2022

Design of Workholding Systems

Posted by Dr. John Ziegert, Ph.D.

Creation of a workholding system is an exercise in engineering design, even if the system is assembled from catalog components. The first step in design is to identify all of the functions that any successful design must...

- Read More | Comments (0) | Nov 15, 2022

.webp)

The Economics of Workholding Systems

Posted by Dr. John Ziegert, Ph.D.

Machining is a subtractive process in which material is removed from an oversized workpiece until the final part geometry is achieved. In traditional machining, a sharp-edged tool is caused to move through the workpiece to...

- Read More | Comments (0) | Nov 15, 2022

Introduction to Workholding

Posted by Dr. John Ziegert, Ph.D.

Everyone in the machining business has heard these two sayings. The first one urges us to optimize productivity and profitability by reducing total cycle time for machining operations. The second reminds us that underutilized...

- Read More | Comments (0) | Nov 14, 2022

Ready to Rock! - Epoxy Mineral Tombstones

Posted by Steve DeGrasse

One of the most AMAZING solutions we have at Advanced Machine & Engineering Co. is our epoxy mineral-based tombstone-technology. However, most people don't know anything about epoxy-mineral tombstones, so I decided to write an article!

Tombstones? Did Someone Die?

No,…

- Read More | Comments (0) | Sep 30, 2022

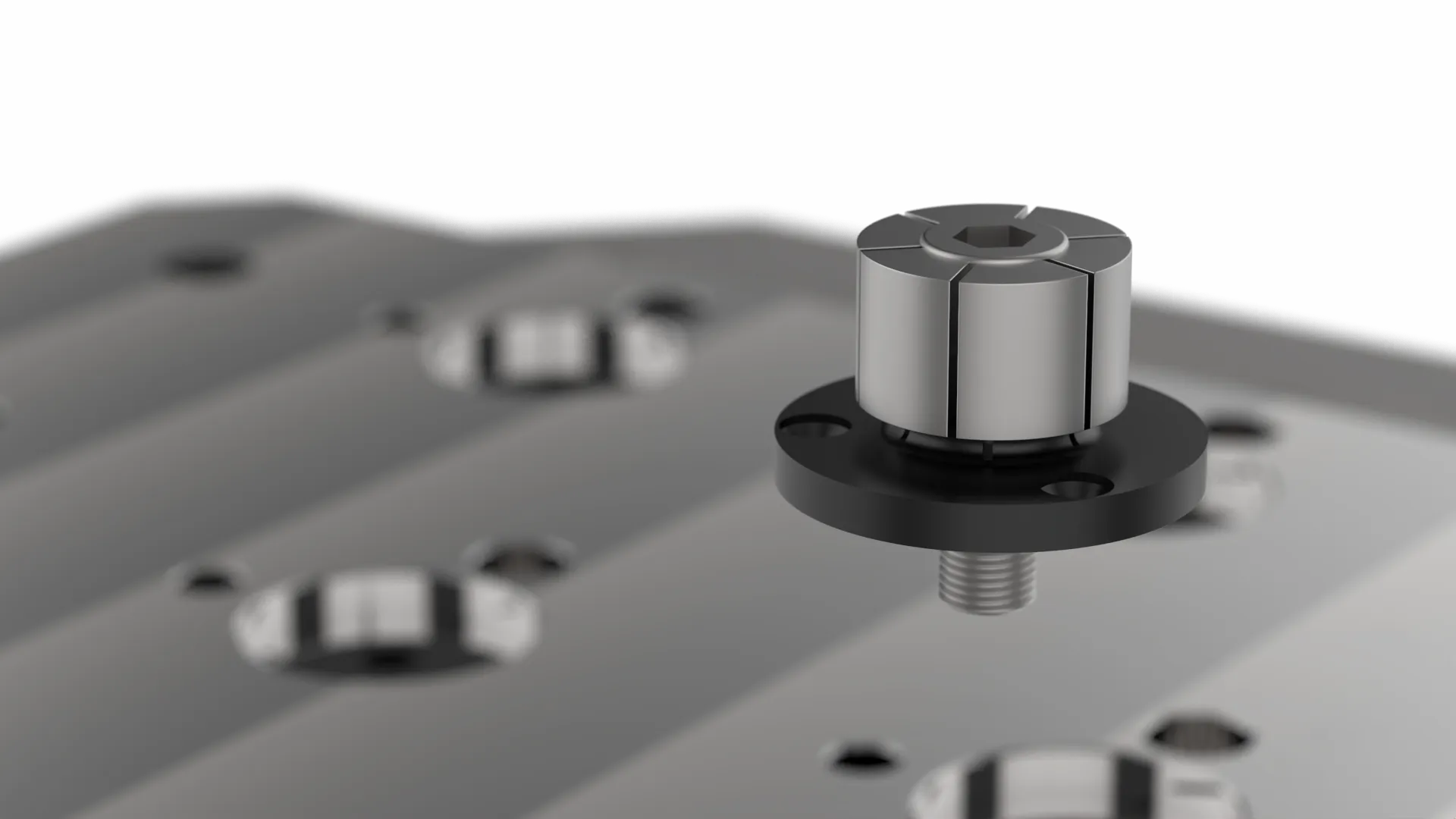

Why You Should Consider Off-Machine Setups for Your Machining Process

Posted by Crystal Van Vleet

If you want to reduce your overall costs and increase your flexibility to meet your customers’ demands, consider incorporating off-machine set-ups into your machining process.

- Read More | Comments (0) | Nov 24, 2021

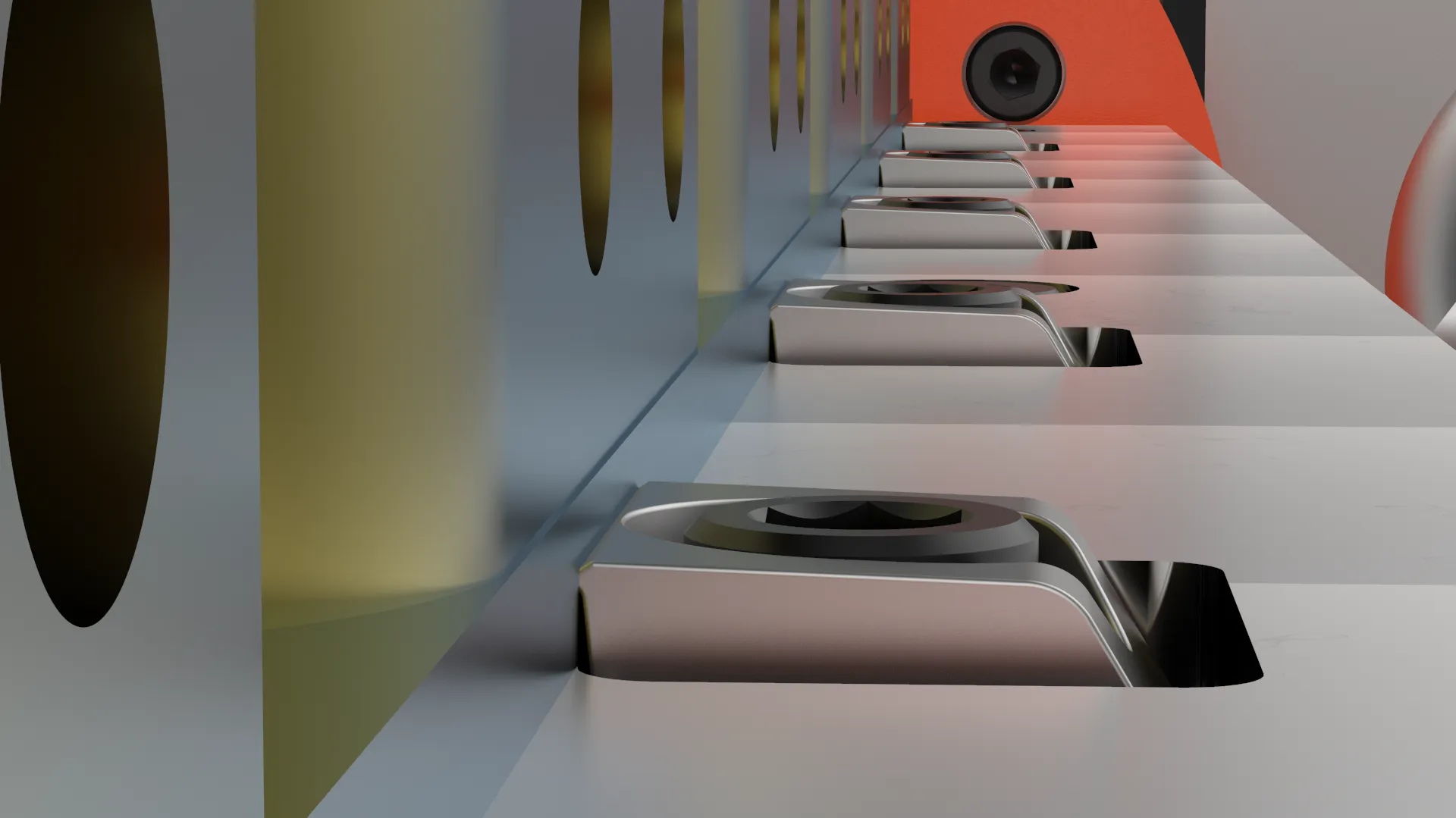

Low-Profile Design and High-Density Workholding—Maximizing Your Machining Envelope

Posted by Crystal Van Vleet

To achieve high throughput and the cost effectiveness of your CNC machine, you need a clamp option that allows for high-density, low-profile workholding with a high clamping force. A low-profile design enables you to maximize your machining envelope for large parts, improving your overall productivity from your machining center.

- Read More | Comments (0) | Nov 18, 2021

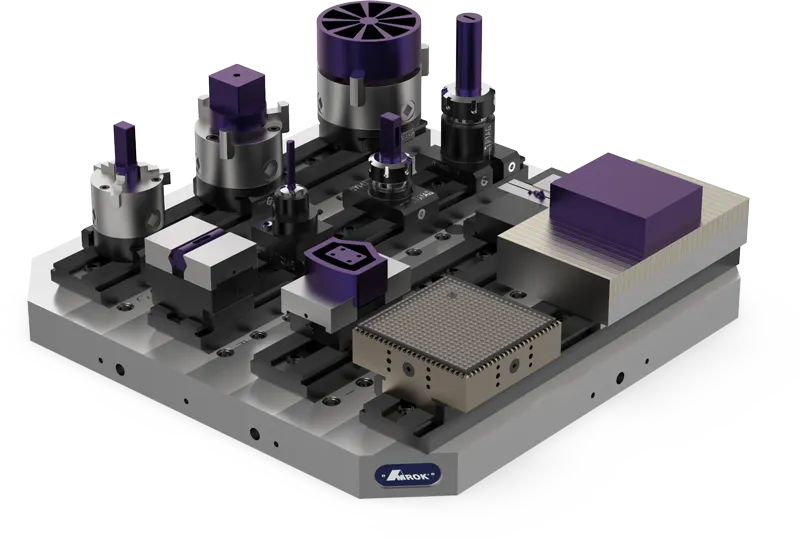

The Top Benefits of a Modular Workholding System

Posted by Crystal Van Vleet

The demand for high quality, tight tolerance, and complex parts continues to increase as automation gains momentum in the industry. A robust workholding system that offers a variety of fixturing options is essential to keeping up with the demand and improving your bottom line.

- Read More | Comments (0) | Nov 18, 2021