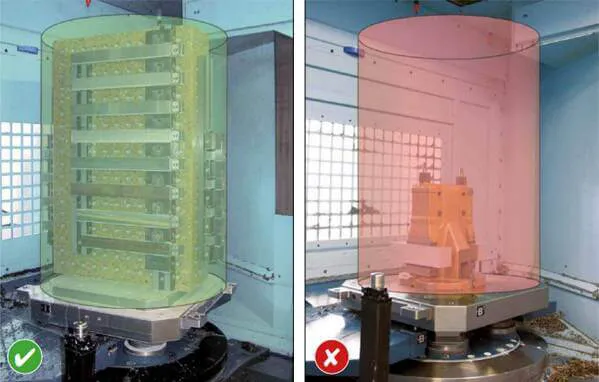

Five Workholding Tips to Eliminate the Wasted Space (and time) that Cuts into your Profit

Posted by Beat Baumgartner

"Wasting space within the machine tool is wasting time and in the business of manufacturing, time is money." - Beat Baumgartner - Triag International AG

- Read More | Comments (0) | Mar 25, 2019

Spending too much time Indicating in your Machine Shop?

Posted by Nick Goellner

That's an indication that you may need to upgrade your workholding foundations from T-slots to Grid Plates.

- Read More | Comments (0) | Mar 25, 2019

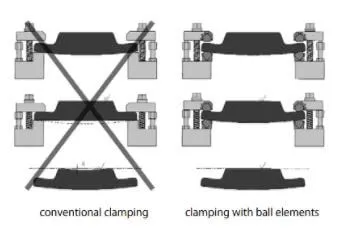

Four Reasons Aerospace Machinists Should Consider Ball Element Clamping Components for Their Applications

Posted by Lonnie Miller

Ball element clamping components offer a one-component, one-and-done setup solution for industries machining precision parts.

- Read More | Comments (0) | Mar 15, 2019

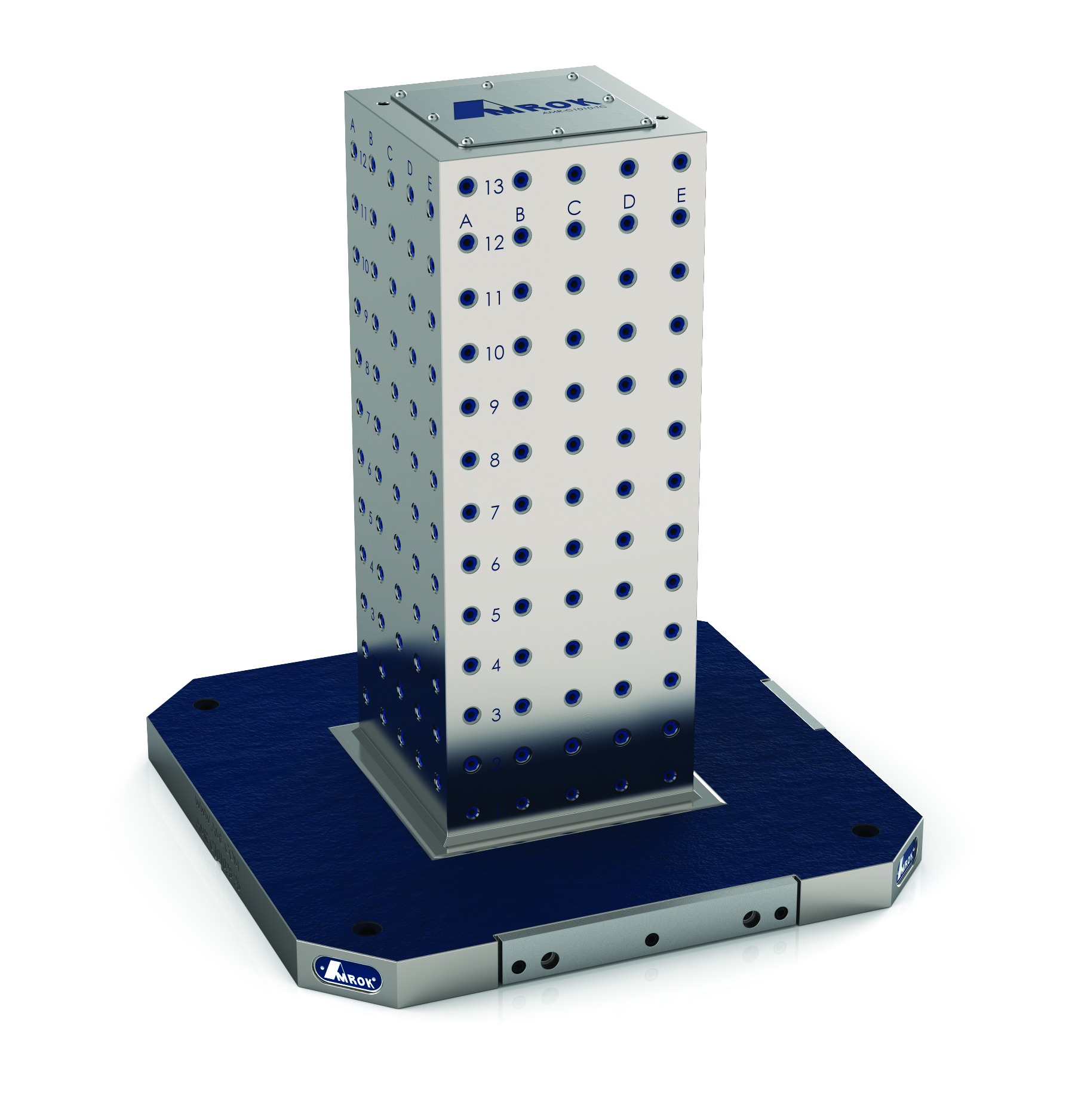

How to Select the Right Material for your Workholding Tombstone

Posted by Nick Rupprecht

There are several things to consider before selecting a material for your workholding tombstone.

- Read More | Comments (0) | Aug 06, 2018

Centering Dovetail Vises Versus Traditional Self-Centering Vises

Posted by Lonnie Miller

When it comes to dovetail workholding, centering dovetail vises offer a variety of benefits compared to traditional self-centering vises including 5-axis machining and true centering.

- Read More | Comments (0) | Jun 13, 2018

How to select the right tombstone fixture shape for your application

Posted by Nick Rupprecht

Workholding tombstone fixtures are available in a variety of shapes and sizes. There are several things to consider for you to select the right tombstone fixture shape for your application.

- Read More | Comments (0) | May 31, 2018

How Modular Clamping Systems Increase Workholding Capacity without Increasing Costs

Posted by Meaghan Ziemba

A modular clamping system allows you to increase your capacity without having to invest in another machining center.

- Read More | Comments (0) | May 16, 2018

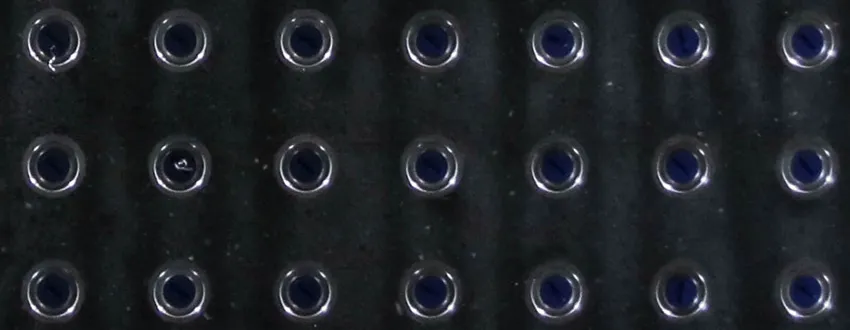

Keep Your Fixture Options Open with 2-Inch Grid Patterns

Posted by Nick Rupprecht

For a versatile and adaptable workholding foundation, 2-inch precision grid plates and grid tombstones allow you to minimize setup and maximize throughput.

- Read More | Comments (0) | Apr 19, 2018