all (30) maximizing uptime (17) optimizing tool life (13) choosing a sawing machine (11) costs & benefits (10) sawing different materials (8) automating a process (6) FAQ (4) other (2)

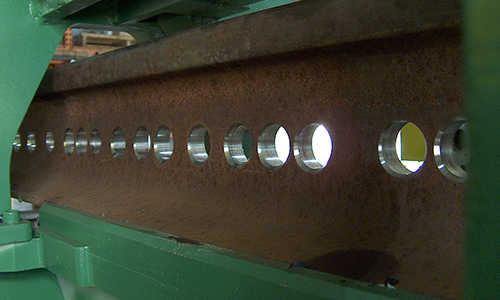

High Production Layer Saws for cutting Multiple Tubes or Bars

By cutting multiple bars or tubes in layers to increase productivity

- Read More | Comments (0) | Oct 16, 2020

4 Ways to Reduce Vibration in Carbide Saws

Here are four ways to help reduce the damaging effects of vibration in your sawing processes.

- Read More | Comments (0) | Feb 07, 2019

When to Use a Slide Saw vs. a Pivot Saw?

Your floor space and layout, budget, and customer needs will determine if a carbide slide saw or carbide pivot saw is best for your machine shop operations.

- Read More | Comments (0) | Dec 03, 2018

Systems for Length Measurement in Metal Bar, Tube, Billet, Rail, and Plate Sawing

Posted by Chris Rindels

There is a lot to consider when selecting the right length measurement system for your application. It is a matter of discrimination on how accurate your measuring needs to be and the costs benefit of each method that is available.

- Read More | Comments (0) | Nov 26, 2018

Vibration Analysis for Carbide Sawing Machines

Vibration analysis for carbide sawing machines is crucial for auditing blade health and quality cuts.

- Read More | Comments (0) | Sep 27, 2018

Infographic: Rail Fabrication Process with Rail Sawing and Drilling

The manufacturing process for rail production involves several steps to ensure the rail's durability and resistance to cracking.

- Read More | Comments (0) | Aug 15, 2018

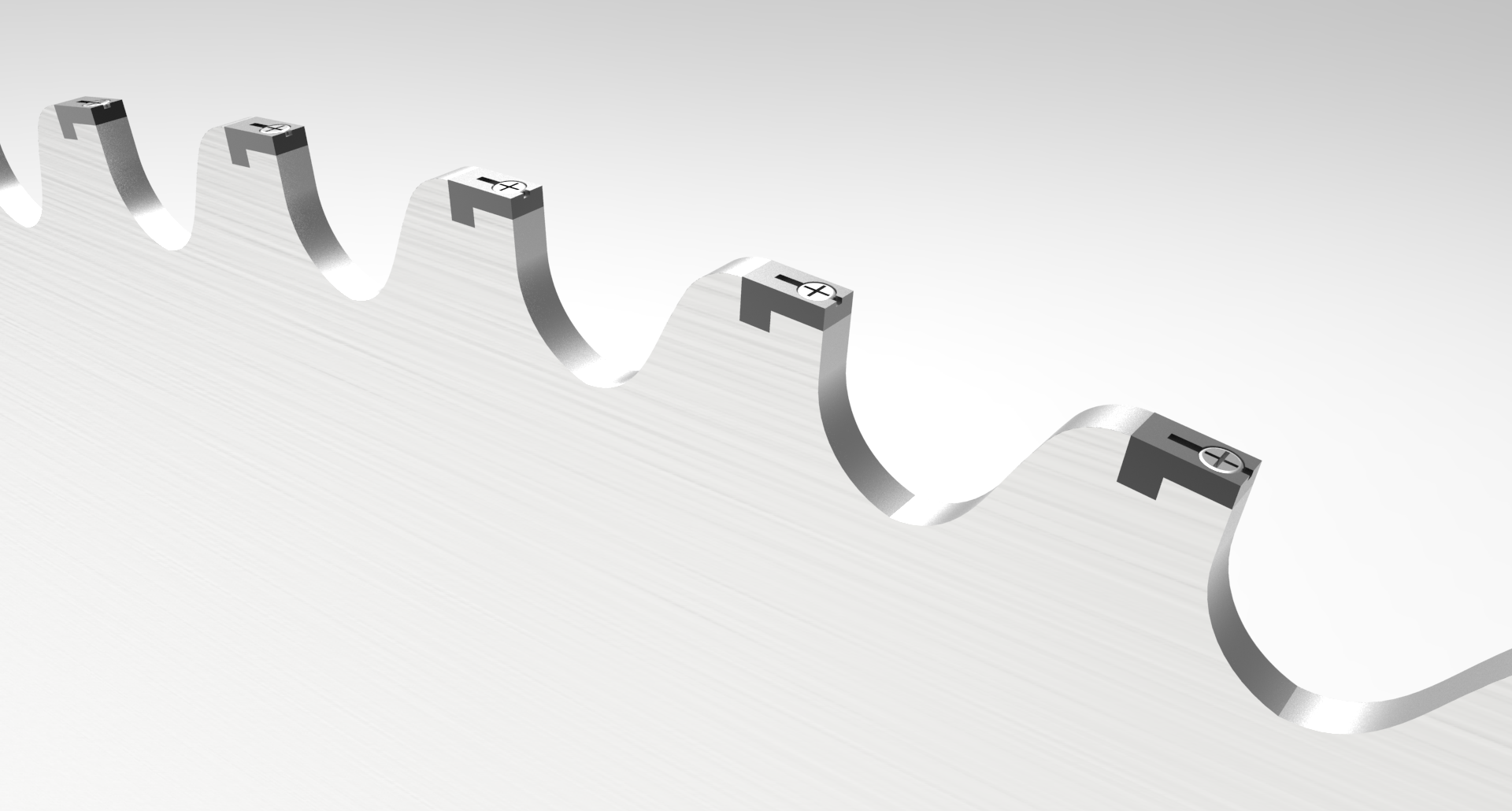

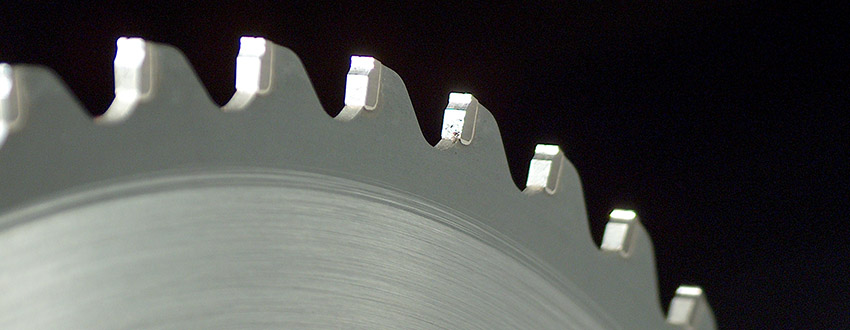

How to Cut Costs Using Different Types of Carbide-Tipped Circular Saw Blades

Carbide-tipped circular saw blades are offered in three versions with different cost structures.

Updated September 2019

- Read More | Comments (0) | May 09, 2018

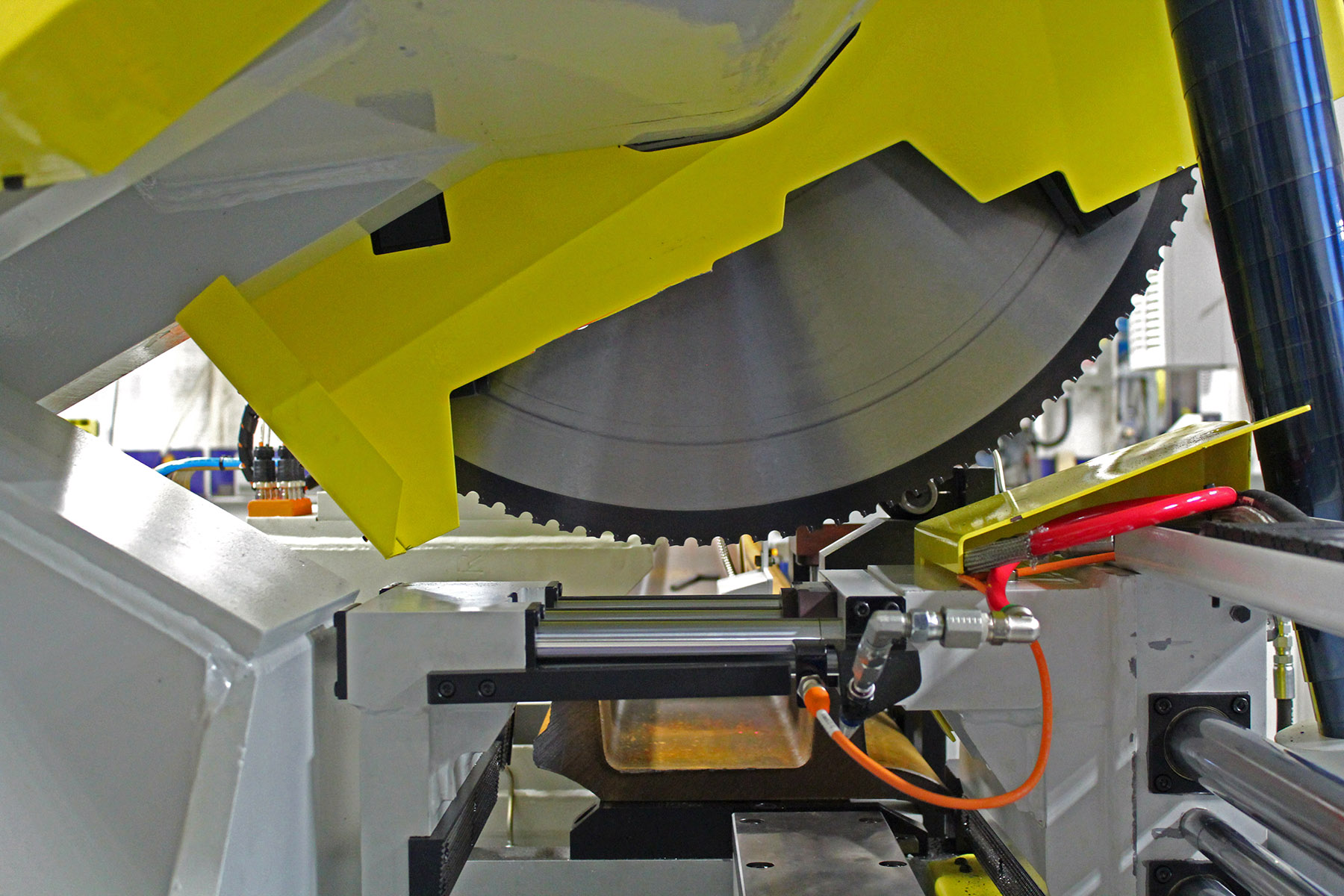

Circular Saw vs. Band Saw: Which One is Best for You?

Let’s cover the differences between circular saws and band saws, and how to choose which one is best for your operation.

- Read More | Comments (1) | Apr 13, 2018

Automating Manufacturing with Rail Sawing and Drilling Processes

Posted by Chris Rindels

Combination machines with material handling streamlines rail sawing and drilling processes -- providing more throughput, increased quality and efficiency, and improved viability.

- Read More | Comments (0) | Apr 06, 2018

Why is a Circular Metal Saw Called a Cold Saw?

Circular cold saws allow both the material and blade to remain cool during the sawing process by transferring the generated heat to the chips.

- Read More | Comments (0) | Mar 23, 2018

Do You Really Know the Cost of Your Carbide Billet Saw?

When you have to cut a lot of alloy steel, cutting speed is an obvious issue - but are you getting the saw for a good price? We'll explain how shock load and operator error can affect the total cost of your carbide billet saw.

- Read More | Comments (0) | Feb 09, 2018