all (30) maximizing uptime (17) optimizing tool life (13) choosing a sawing machine (11) costs & benefits (10) sawing different materials (8) automating a process (6) FAQ (4) other (2)

Do You Really Know the Cost of Your Carbide Billet Saw?

When you have to cut a lot of alloy steel, cutting speed is an obvious issue - but are you getting the saw for a good price? We'll explain how shock load and operator error can affect the total cost of your carbide billet saw.

- Read More | Comments (0) | Feb 09, 2018

What Circular Saw Blade Tooth Geometry is Best for Sawing Steel Billets?

The heat from the cutting process, especially using negative cutting angles when cutting steel, transfers to the chip, causing it to expand and jam in the slot. This can be prevented by splitting the chip. There are two common tooth geometries developed to split the chip: “Triple Chip” and “Notch Grind.”

- Read More | Comments (0) | Dec 20, 2017

Key Calculations for Maximizing Tool Life in Carbide Saws

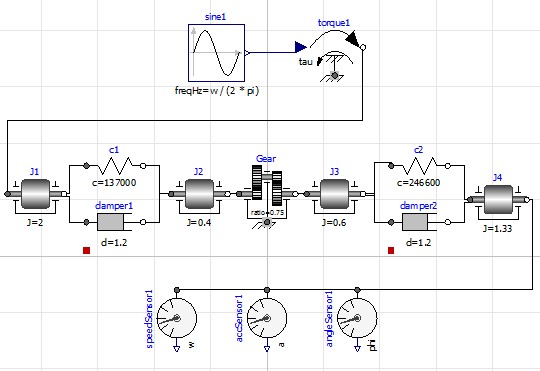

Torsional vibrations are hard to measure because of the rotating elements (gears, shafts) that are inside a closed gear case and not easily accessible. However, knowing the exciting torque, passing through the gear train and the gear data, critical vibrations such as resonance can be calculated and analyzed. The calculations and theoretical analysis shown in this article show that much can be theoretically analyzed, where practical limitations exist.

- Read More | Comments (0) | Nov 14, 2017

Innovative Devices to Maximize a Carbide Saw's Blade Life

There are several proven methods to minimize backlash and reduce vibration during the carbide sawing cycle. The most damaging aspect of the sawing process is the entering and exiting of the circular blade in and out of the material. The "hammering" effect at the beginning and ending of the saw process can severely damage the carbide teeth of the saw blade. Saw machine designers have created several devices of varying complexity and costs to minimize these problems.

- Read More | Comments (0) | Sep 28, 2017

These 13 Issues Will Destroy High Production Carbide Tipped Circular Saw Blades

Achieve the highest productivity in metal sawing by taking care of your carbide tips. Production managers and manufacturing engineers choose circular carbide saw systems when they need the sawing method with the highest productivity. Without a doubt, circular sawblades equipped with carbide teeth are the most productive tool for high production metal sawing, but if you are replacing your blades too often, high productivity will be negated by the high cost of tooling and the lengthy changeover time.

- Read More | Comments (0) | Sep 13, 2017

Minimizing the Damaging Effect of Vibration and Resonance with Stabilizers and Dampers

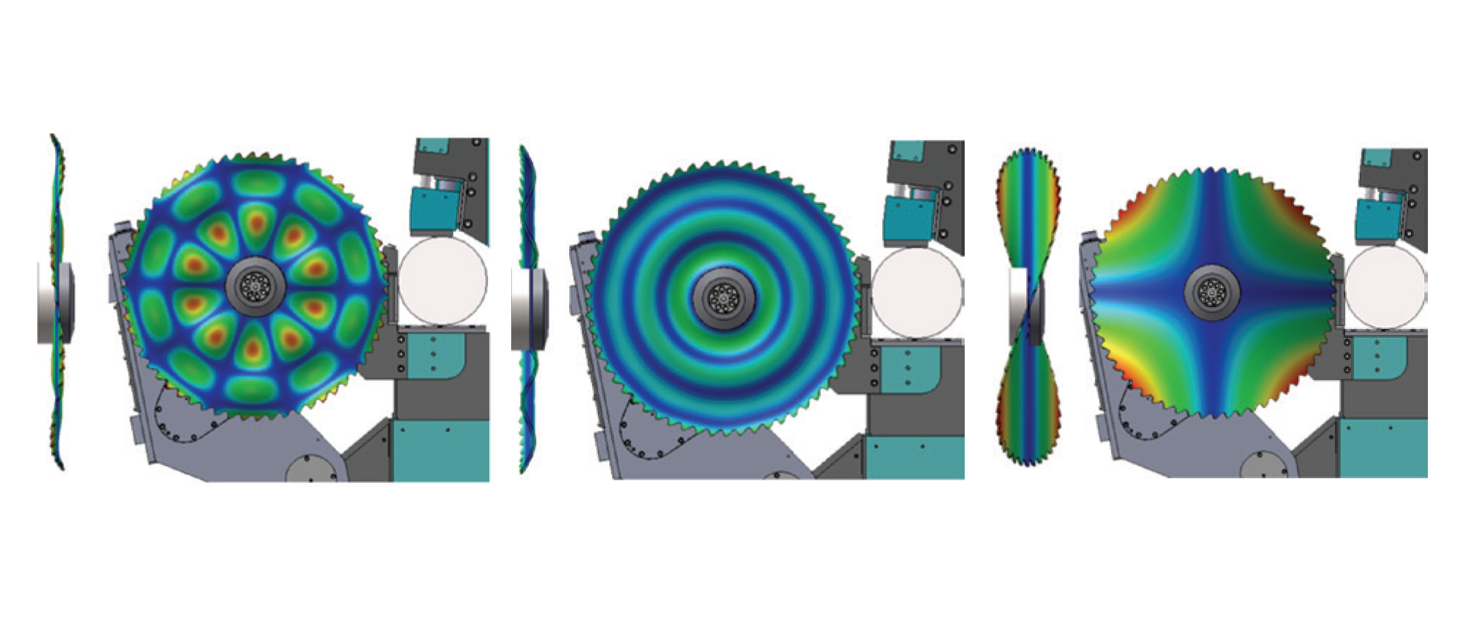

This third and final article in the current series describes how to best minimize the damaging effects of vibrations and resonance with stabilizers and dampers. Even with a well-designed carbide saw, blade vibrations still occur. That is because it is nearly impossible to take into account every possible cause of vibration. Understanding stabilizing and damping best practices is the key to minimizing the inevitable vibrations that occur during the sawing process.

- Read More | Comments (0) | Aug 14, 2017

Resonance – The Destructive Force Behind Carbide Saw Breakdowns

In this second of three articles, we focus on the destructive force behind carbide saw breakdowns with an in-depth look at resonance. Do not let resonance destroy your sawing machine and ruin efficiency within your shop. Learn how to test resonance and prevent a catastrophic outcome.

- Read More | Comments (0) | Aug 01, 2017

Effect and Prevention of Vibration in Carbide Sawing

Vibration is harmful in any sawing machine, but in high production saws with hard and brittle carbide-tipped blades, it can be catastrophic. Reducing vibration is the main focus for machine designers, because vibration dramatically affects the tool life of the saw blade and increases the overall cost-per-cut. This article – which is first of a three-part series – focuses on the damaging effect and prevention of vibration in carbide sawing.

- Read More | Comments (0) | Jul 03, 2017

Measuring Compliance - The Weakness in Your Carbide Saw

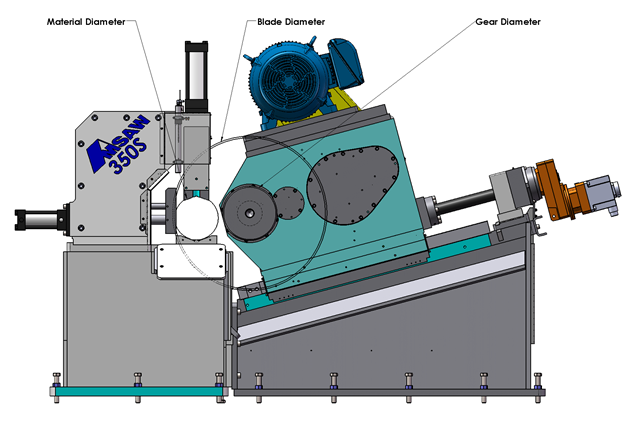

Compliance is defined as the measure of the ability of a mechanical system to respond to an applied vibrating force, expressed as the reciprocal of the system stiffness. In short, it measures the weakness of the system. In a carbide saw, the most critical component subject to torsional and lateral vibration of the saw blade, is the gearbox, commonly called the head.

- Read More | Comments (0) | Jun 12, 2017

Torsional Vibrations in Carbide Sawing

Torsional vibration in carbide saws has the most damaging effect on the tool life of carbide tipped circular saw blades. It is also influenced by the blade diameter, the quality of the saw blades, the spindle gear diameter, the compliance of the gear train in the saw head and feed system, and the stiffness of the fixture and machine structure.

- Read More | Comments (3) | Jun 05, 2017

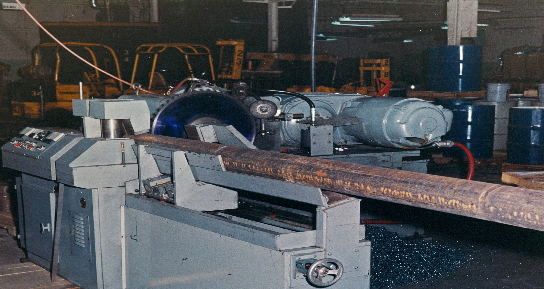

The History of Carbide Sawing

The name carbide saw came from the tool, a circular saw blade, with silver soldered carbide tips. It competed with and just about replaced, solid or segmental HSS blades, because carbide is much harder than HSS. Before HSS saws were developed, abrasive, friction or hot saws were used and are still manufactured for certain applications. These processes create heat and are therefore called hot saws.

- Read More | Comments (3) | Feb 08, 2017