Centering Dovetail Vises

- Home

- >

- Fixturing Components

- >

- AMROK Modular Workholding

- >

- Vise Systems

- >

- Centering Dovetail Vises

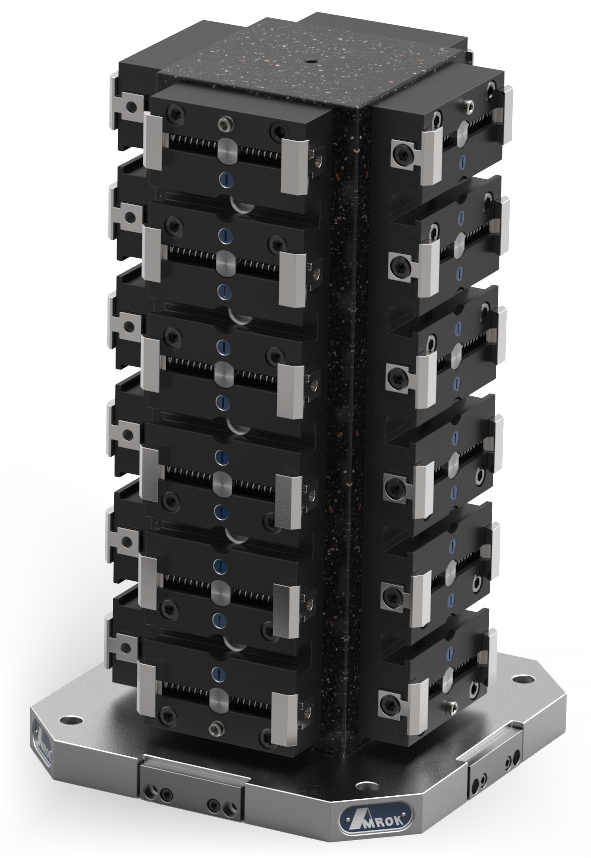

Centering Dovetail Vises

5 Axis Workholding Systems for Gripping Work

Finding a more efficient way to hold parts should be simple. There are many workholding options, but if you’re searching for something that is easy to use and can reduce setup times, the patented Centering Dovetail Vise (CDV) is the perfect solution.

Here’s how it works:

1. Attach the CDV unit to a standard 2-inch grid using precision locating screws.

2. Clamp your part with a pre-machined dovetail and counterbored holes for locating.

3. Start machining!

Find out if the AMROK’s CDV system works for your application here. Stop searching, start machining.

STANDARDIZATION

- All parts are prepped in the same manner

- All manufacturing operations are set up the same way

- All parts are clamped and located the same way

COST SAVINGS

- Parts can be prepped off-line at a reduced mfg. cost

- Many different parts can be held using the same CDV

- Requires minimal excess stock to clamp and locate parts

- No additional custom workholding components are required

TIME SAVINGS

- No change-over of jaws to hold different parts

- No additional components needed to clamp and locate parts

- No adjusting of stop to locate parts

- 5-sided machining of parts is made possible

- Multiple parts can be machined on a single CDV

EASE OF USE

- All parts are clamped and located the same way

- Easily load and unload parts

- Virtually no training is required for operators

- Additional jaw assemblies can be added quickly

- Easy to disassemble if maintenance is required

SCRAP REDUCTION

- Eliminates distortion in machined parts do to clamping forces

- Securely holds parts so they do not become loose during machining

- Machined parts can be removed and precisely reloaded in CDV

FITS ON A STANDARD 2” GRID SYSTEMS

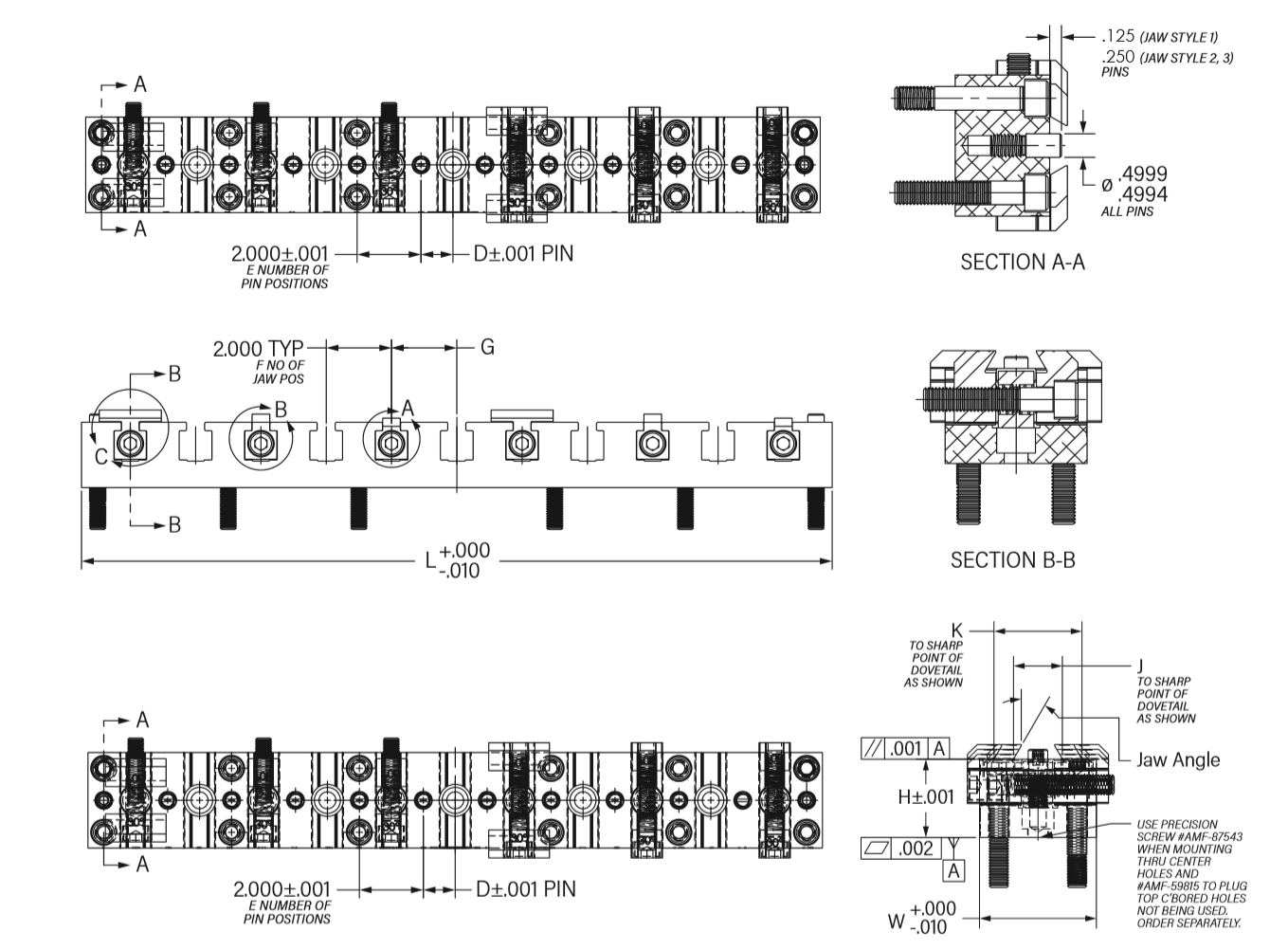

All vises are designed to fit on the industry standard 2” center to center hole pattern using precision screws and 1/2-13 SHCS (included in each assembly). This grid system mounting allows for between center mounting, on center mounting, Bridgeport mounting, and T-slot mounting; all with no additional sub-plate for tombstone mounting. The two outside holes and the center hole closest to each end are precision mounting holes.

HIGH TORQUE/HEAVY LOADS

Various jaw widths and heights for better load distribution and workpiece clamping.