Finding the Right Tombstone is Easy with AME

Posted by Levi Johnston

AME provides a handy guide on how to select the right tombstone from their wide range of products.

- Read More | Jun 22, 2023

Okuma’s Partners in THINC Spotlights AME Workholding and Automation Expertise

Posted by Levi Johnston

AME is part of Okuma America’s Partners in THINC network, enhancing productivity, driving innovation, and bringing vast workholding and automation knowledge to end-users.

- Read More | Apr 27, 2023

Overview of Workholding System Components - Part 2

Posted by Dr. John Ziegert, Ph.D.

The one component that is common to all workholding systems is a method for clamping the part(s). As we discussed earlier, machining involves forces that can be significantly high, and a clamping system is needed to restrain...

- Read More | Nov 15, 2022

Design of Workholding Systems

Posted by Dr. John Ziegert, Ph.D.

Creation of a workholding system is an exercise in engineering design, even if the system is assembled from catalog components. The first step in design is to identify all of the functions that any successful design must...

- Read More | Nov 15, 2022

.webp)

The Economics of Workholding Systems

Posted by Dr. John Ziegert, Ph.D.

Machining is a subtractive process in which material is removed from an oversized workpiece until the final part geometry is achieved. In traditional machining, a sharp-edged tool is caused to move through the workpiece to...

- Read More | Nov 15, 2022

Introduction to Workholding

Posted by Dr. John Ziegert, Ph.D.

Everyone in the machining business has heard these two sayings. The first one urges us to optimize productivity and profitability by reducing total cycle time for machining operations. The second reminds us that underutilized...

- Read More | Nov 14, 2022

Ready to Rock! - Epoxy Mineral Tombstones

Posted by Steve DeGrasse

One of the most AMAZING solutions we have at Advanced Machine & Engineering Co. is our epoxy mineral-based tombstone-technology. However, most people don't know anything about epoxy-mineral tombstones, so I decided to write an article!

Tombstones? Did Someone Die?

No,…

- Read More | Sep 30, 2022

Why You Should Consider Off-Machine Setups for Your Machining Process

Posted by Crystal Van Vleet

If you want to reduce your overall costs and increase your flexibility to meet your customers’ demands, consider incorporating off-machine set-ups into your machining process.

- Read More | Nov 24, 2021

Low-Profile Design and High-Density Workholding—Maximizing Your Machining Envelope

Posted by Crystal Van Vleet

To achieve high throughput and the cost effectiveness of your CNC machine, you need a clamp option that allows for high-density, low-profile workholding with a high clamping force. A low-profile design enables you to maximize your machining envelope for large parts, improving your overall productivity from your machining center.

- Read More | Nov 18, 2021

The Top Benefits of a Modular Workholding System

Posted by Crystal Van Vleet

The demand for high quality, tight tolerance, and complex parts continues to increase as automation gains momentum in the industry. A robust workholding system that offers a variety of fixturing options is essential to keeping up with the demand and improving your bottom line.

- Read More | Nov 18, 2021

The Balance Between High Accuracy, Quick Change Systems, and Zero-Point Clamping

Posted by Crystal Van Vleet

Need to improve your machine’s throughput? This is how you do it by decreasing setup time and overall costs.

- Read More | Sep 20, 2021

High-Density Workholding with Mitee-Bite Uniforce Clamps

Posted by Crystal Van Vleet

Machinists are always focusing on how to improve their productivity: machining more parts at once with a faster setup. As shops continue to search for the next best workholding system, they tend to find success in extreme high-density workholding.

- Read More | May 03, 2021

Overview of Workholding System Components - Part 1

Posted by Dr. John Ziegert, Ph.D.

In part seven of our stationary workholding and machining fixtures series, we discusses how to evaluate and compare various workholding system components.

- Read More | Mar 26, 2021

Vibrations and Their Effect on Workholding Solutions

Posted by Dr. John Ziegert, Ph.D.

In our latest stationary workholding and fixturing article, learn how your tombstone will respond to vibrations.

- Read More | Mar 17, 2021

The Role of Stiffness in Workholding

Posted by Dr. John Ziegert, Ph.D.

In the fifth article of our multi-part series, learn how to calculate how the elements of a workholding system respond to cutting forces.

- Read More | Mar 10, 2021

Cutting Forces in Milling: The Formula for Successful Workholding

Posted by Dr. John Ziegert, Ph.D.

AME explains how to calculate cutting forces generated during milling operations in order to select the correct workholding system.

- Read More | Mar 01, 2021

Designing Workholding Systems

Posted by Dr. John Ziegert, Ph.D.

We're back with part three of our stationary workholding and machining fixtures series. Join expert John Ziegert as he discusses how to design your ideal workholding system.

- Read More | Feb 10, 2021

The Economics of Workholding Systems

Posted by Dr. John Ziegert, Ph.D.

In part two of our stationary workholding and machining fixtures series, expert John Ziegert discusses the economics of machine workholding.

- Read More | Jan 18, 2021

Developing a Custom Hydraulic Workholding Solution

Posted by Crystal Van Vleet

When implemented on a tombstone, hydraulic workholding fixtures can offer a significant increase in CNC machine productivity and allow multiple different parts to be machined in a single run.

- Read More | Dec 01, 2020

The Secret Behind Low CNC Machine Downtime

Posted by Dr. John Ziegert, Ph.D.

In part one of our stationary workholding and machining fixtures series, our expert discusses how to improve the productivity of your operations.

- Read More | Nov 24, 2020

Using Hydraulic Clamping to Your Advantage

Posted by Crystal Van Vleet

Pivoting to a solution featuring hydraulic workholding fixtures can save time and reduce error.

- Read More | Nov 17, 2020

Improving Throughput with 4th-Axis Rotary Tables

Posted by Meaghan Ziemba

When working with a VMC, a traditional 3-axis setup can be limiting—integrating 4th-axis CNC rotary table capabilities can improve flexibility and throughput.

- Read More | Nov 02, 2020

Building a Custom Hydraulic Fixturing Solution

Posted by Crystal Van Vleet

An aerospace supplier was in need of a large and complex hydraulic fixturing solution. With a model already created in CAD, they were seeking a build partner who could assemble and test it for them.

- Read More | Oct 30, 2020

Eliminating Wasted Material with 5th Axis Workholding

Posted by Levi Johnston

Dovetailing has long been considered one of the strongest ways to join wood. How can manufacturers utilize dovetail vise jaws for more efficient 5-axis machining?

- Read More | Oct 12, 2020

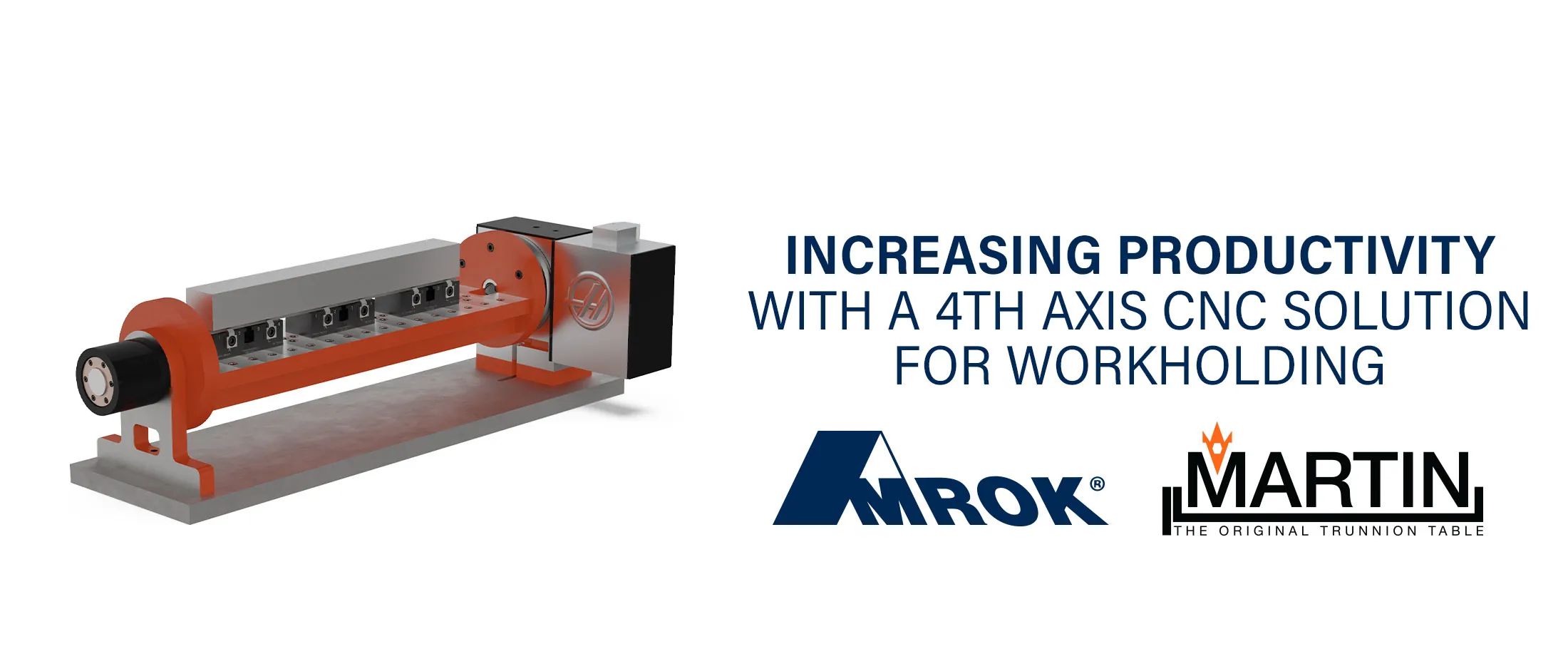

Increasing Productivity with a 4th Axis CNC Solution for Workholding

Posted by Levi Johnston

How Martin’s Stallion trunnion table system and AME’s CDV improve efficiency for vertical machining centers.

- Read More | Jun 24, 2020

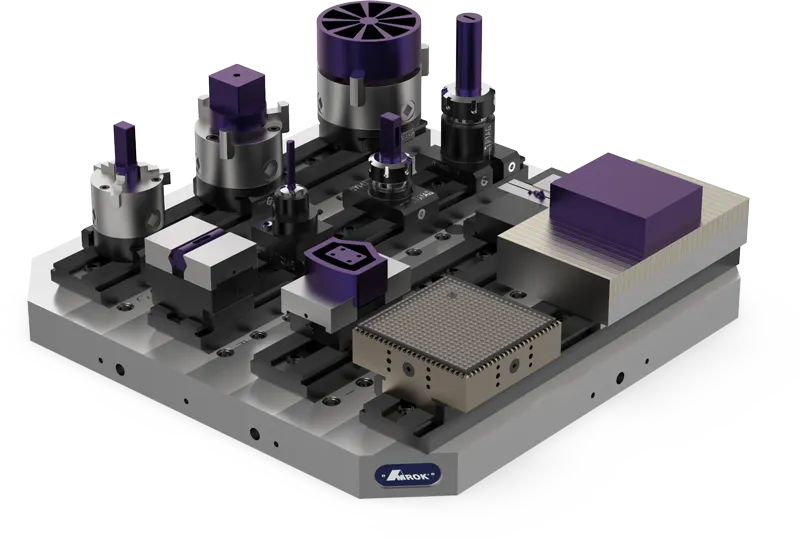

The Value-Add of Collaboration: How Outside Partners Can Drive Growth

Posted by Nick Goellner

When customers think of AMROK, the first thing that seems to come to mind is “leaders in tombstone manufacturing”, and that is certainly a reputation we are proud of and feel we have earned. However, what customers may not realize is that tombstones are just a small segment of our company. Through the years, we’ve also cultivated a reputation for building and maintaining strong…

- Read More | May 29, 2020

How To: Maximize the Potential of Your Machining Envelope with Modular Vises

Posted by Crystal Van Vleet

Where can you make adjustments to take advantage of maximizing your shop’s potential while harnessing the creativity of your engineers, machinists, and operators?

- Read More | May 06, 2020

4th-Axis Workholding Systems Provide Streamlined, Efficient Setup

Posted by Meaghan Ziemba

There are many advantages to upgrading your workholding setup to include a modular, 4th-axis workholding system, and a simpler, more streamlined, and more efficient setup are just the start.

- Read More | Apr 23, 2020

.webp)

4th-Axis Workholding Provides Improved Efficiency

Posted by Crystal Van Vleet

Improve your throughput by upgrading your vertical machining center (VMC) setup to include a full 4th-axis workholding trunnion and modular fixturing system.

- Read More | Mar 31, 2020

Tombstone Testing for Dynamic Performance

Posted by Meaghan Ziemba

Because tombstones support the workpiece during machining, their dynamic response becomes part of the entire system. The goal of this effort was to measure the dynamics individually and then as part of a machine set up. All tests were conducted by Dr. Tony L. Schmitz, a world renowned mechanical engineering professor at the University of Tennessee, Knoxville and Joint Faculty at Oak RIdge National Laboratory, who specializes in machine tool research and manufacturing engineering.

- Read More | Jan 21, 2020

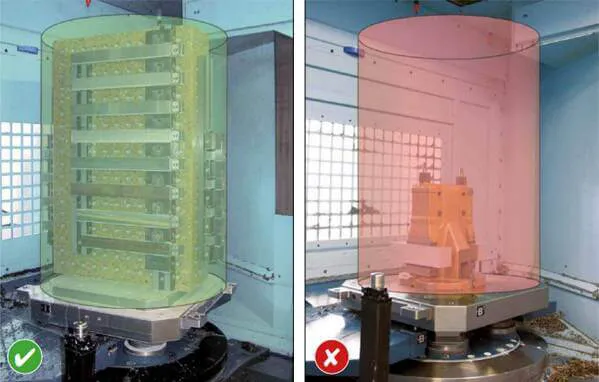

Five Workholding Tips to Eliminate the Wasted Space (and time) that Cuts into your Profit

Posted by Beat Baumgartner

"Wasting space within the machine tool is wasting time and in the business of manufacturing, time is money." - Beat Baumgartner - Triag International AG

- Read More | Mar 25, 2019

Spending too much time Indicating in your Machine Shop?

Posted by Nick Goellner

That's an indication that you may need to upgrade your workholding foundations from T-slots to Grid Plates.

- Read More | Mar 25, 2019

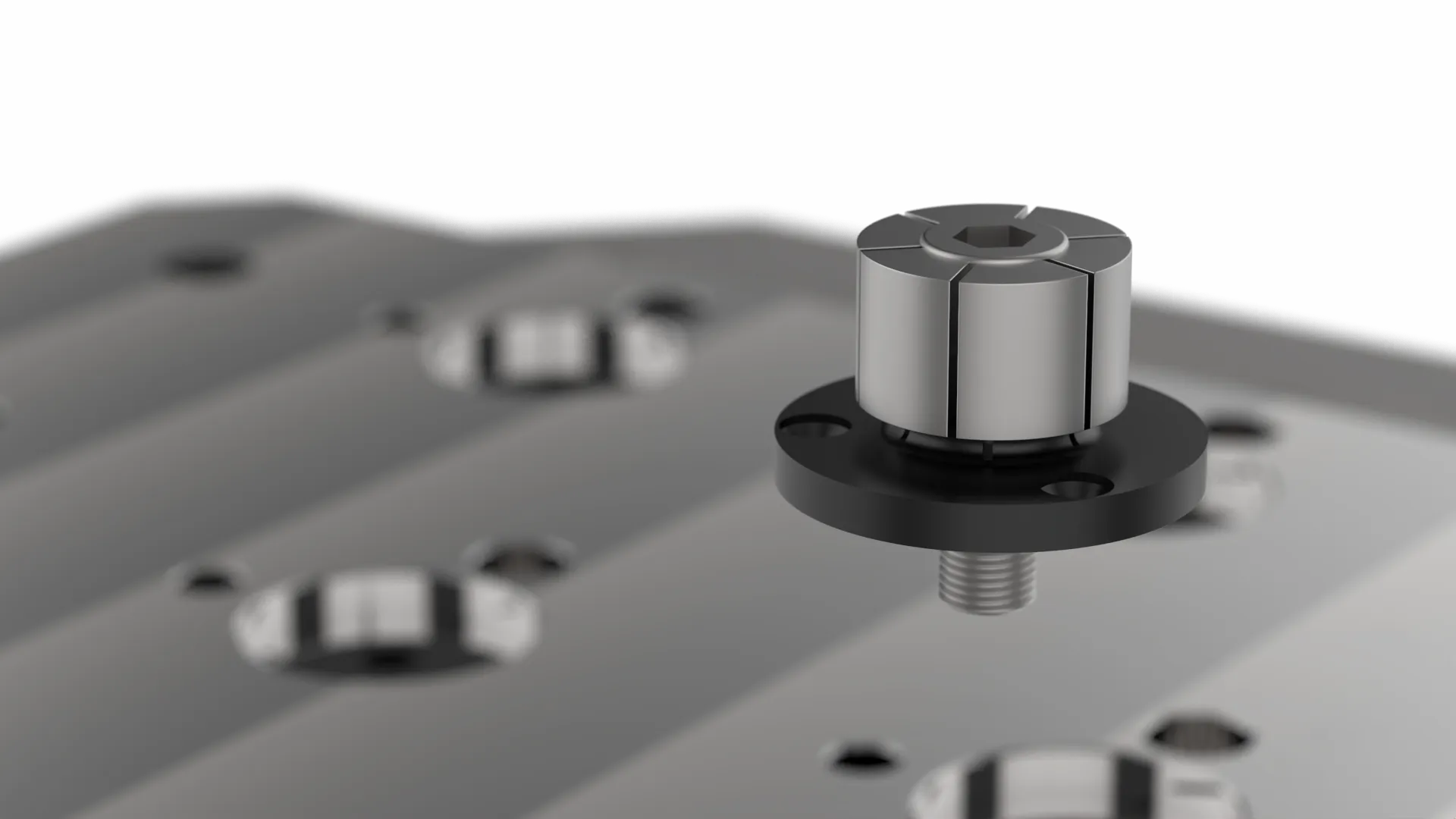

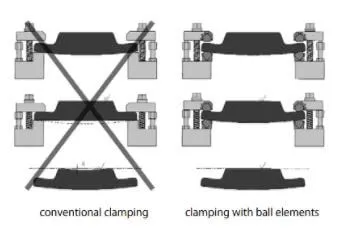

Four Reasons Aerospace Machinists Should Consider Ball Element Clamping Components for Their Applications

Posted by Lonnie Miller

Ball element clamping components offer a one-component, one-and-done setup solution for industries machining precision parts.

- Read More | Mar 15, 2019

How to Select the Right Material for your Workholding Tombstone

Posted by Nick Rupprecht

There are several things to consider before selecting a material for your workholding tombstone.

- Read More | Aug 06, 2018

Centering Dovetail Vises Versus Traditional Self-Centering Vises

Posted by Lonnie Miller

When it comes to dovetail workholding, centering dovetail vises offer a variety of benefits compared to traditional self-centering vises including 5-axis machining and true centering.

- Read More | Jun 13, 2018

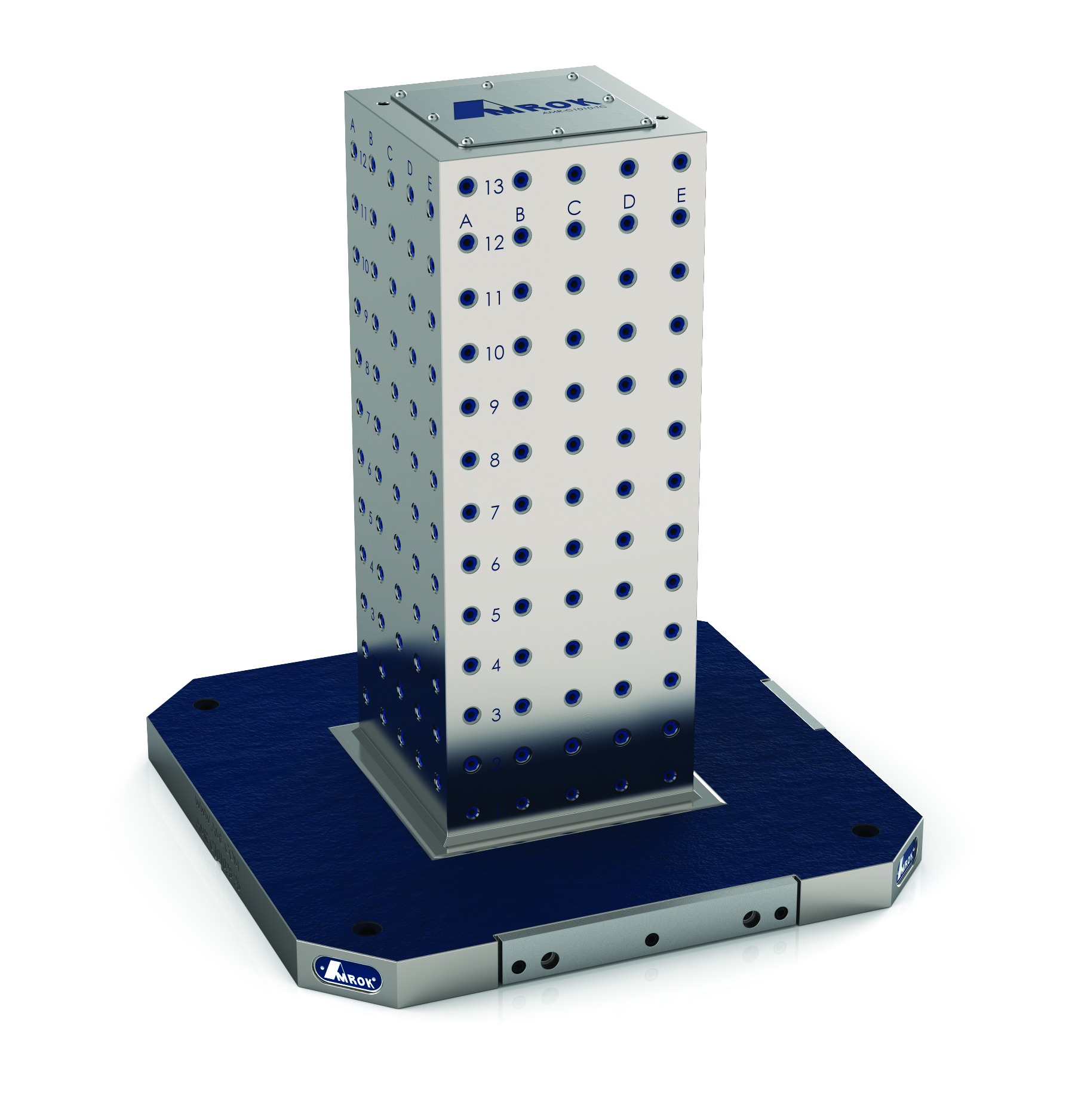

How to select the right tombstone fixture shape for your application

Posted by Nick Rupprecht

Workholding tombstone fixtures are available in a variety of shapes and sizes. There are several things to consider for you to select the right tombstone fixture shape for your application.

- Read More | May 31, 2018

How Modular Clamping Systems Increase Workholding Capacity without Increasing Costs

Posted by Meaghan Ziemba

A modular clamping system allows you to increase your capacity without having to invest in another machining center.

- Read More | May 16, 2018

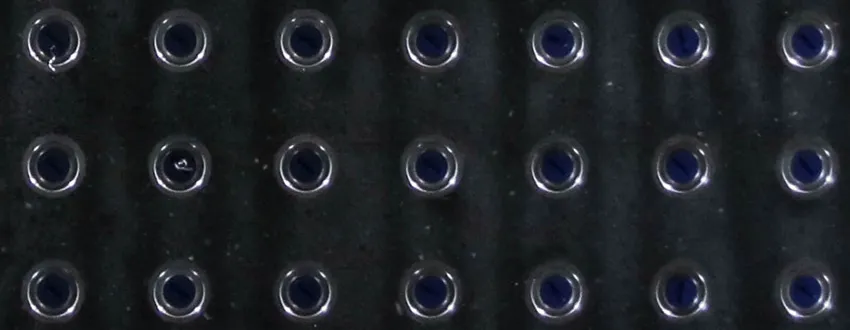

Keep Your Fixture Options Open with 2-Inch Grid Patterns

Posted by Nick Rupprecht

For a versatile and adaptable workholding foundation, 2-inch precision grid plates and grid tombstones allow you to minimize setup and maximize throughput.

- Read More | Apr 19, 2018