Advanced fixture design requires experience, skill, and creativity

Design and Build is in our DNA

A predictable and repeatable machining operation relies on a fixture you can trust. Success in this industry demands more automation and less waste.

We Build Fixtures that Make Our Customers Successful

▶ Competitive lead times ▶ Robotic integration ▶ Operator friendly design

At Advanced Machine and Engineering, workholding is what we do. We build products and solution that stand the test of time while also providing you with endless possibilities in your future in workholding. AME's workholding group is outfitted with engineering experts and workholding specialists that work with your team.

CUSTOM FIXTURE DESIGN AND BUILD PROJECTS

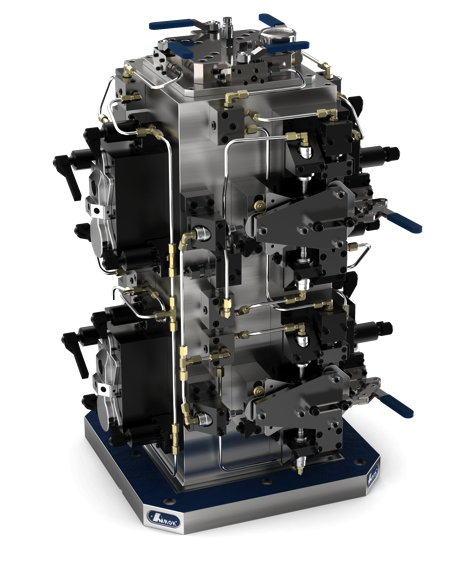

CUSTOM HYDRAULIC & PNEUMATIC FIXTURES

Maximize productivity by saving time between cycles with the convenience of hydraulic or pneumatic power for clamping and unclamping. Benefit from the advanced automation expertise of the AMROK® engineering team.

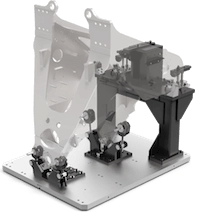

CUSTOM MANUAL FIXTURES

Efficiently change parts using custom-made fixtures designed to accommodate workpieces of various shapes and sizes.

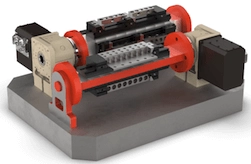

CUSTOM FIXTURES FOR 4TH-AXIS TRUNNIONS

Boost the efficiency of your vertical machining center with a customized 4th Axis Workholding Solution.

ONE-STOP TURN-KEY WORKHOLDING

Searching for a comprehensive solution for all your workholding needs? Look no further. At AMROK, we take care of every aspect of workholding, from design and manufacturing to assembly and testing. With our extensive range of tombstones, trunnion tables, fixture plates, and workholding components, we serve as your one-stop workholding integrator.

CMM INSPECTION FOR PART ACCURACY

Our fixtures undergo rigorous quality checks using large-scale, state-of-the-art CMMs (Coordinate Measuring Machines) in a temperature-controlled environment to meet the tightest tolerance requirements. This ensures an accurate machining platform for your parts. CMM reports are available upon request.

CLEVER FIXTURING CONCEPTS WITH RAPID RESPONSE

Contact our expert fixture engineers directly to discuss your specific fixturing applications. Our experienced engineering team can promptly provide you with a 3D CAD model of your custom fixture, allowing you to review and verify the design.

BUILD TO PRINT WITH A LITTLE PERSPECTIVE.

Looking for something unique? Want us to offer our two cents on your fixture design? No problem.

Want us to manufacture it to your print?

Let’s Work Together

Custom machining fixtures designed for the highest productivity

- Fully-automated hydraulic workholding

- Pneumatic quick-change fixtures

- Manual clamping fixtures made with precision workholding components

- Robotic integration and machine tending for multi-pallet machining cells

High Volume or High Mix - Every Second Counts

Turnkey Workholding -Engineered to be Advanced

- Automate using manual, hydraulic, or pneumatic clamping

- Supply a design for AMROK® to build

- Collaborate with the AMROK® team from start to finish

- Over 30 years of workholding experience

- Designed and made in the USA

DESIGN AND BUILD GOES FAR BEYOND THE FIXTURE

- AME designs and builds custom machinery and machine tool peripherals

- Staffed with a complete team of mechanical, electrical, controls, and fluid power engineers

- Check out our Machine Design group for examples of our work