BEYOND THE INDUSTRY STANDARD

AMROK® Tombstones and Fixture Plates are meticulously designed to meet the industry's most stringent tolerances for flatness, parallelism, perpendicularity, surface finish, and hole location. Every Tombstone and grid plate undergoes a rigorous inspection process using AME's in-house Coordinate Measuring Machine (CMM).

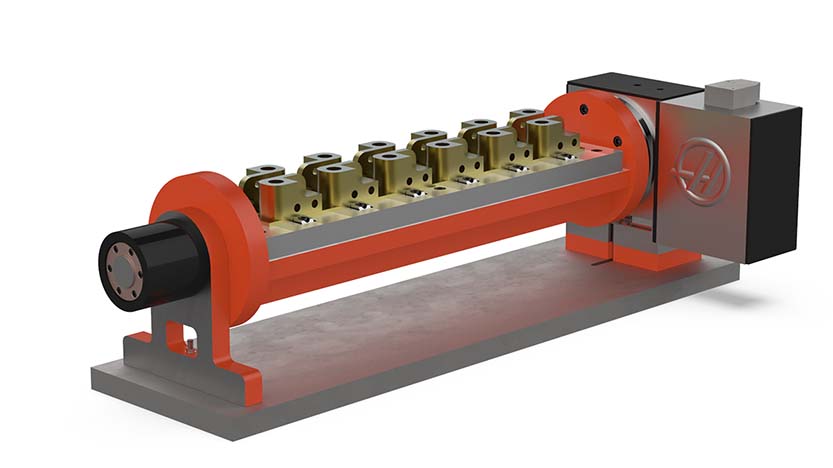

MACHINING & CONFIGURATIONS FOR TOOLING COLUMNS

AMROK® precision-manufactured tombstones, tooling columns, and fixture plates meet the highest standards of precision and quality. Our products feature precision tolerances to ensure optimal performance.

With co-axially positioned bushings, our inserts enable precise positioning and clamping in every hole. They offer excellent wear resistance and are easily replaceable, thanks to hardened precision bushings.

We also provide replacement bushings and insert kits, along with an extraction tool, to facilitate any necessary replacements.

| Tolerance | Precision |

|---|

| Flatness (tombstones & plates) |

.0005 / 12x12 |

| Parallelism (plates) |

.0005 / 12 Max .002 total |

| Perpendicularity |

.0008 / 12 Min .001, Max .002/48 |

| Surface Finish |

63 RMS |

| Face Thickness |

≤18” = ±.001, >18” = ±.002 |

| Tapped Holes (non accumulative) |

±.005 |

| Precision Bushing I.D. |

-0 / +.0006 |

| Precision Bushing Concentricity |

0.0001 |

| Bored or Precision Bushing Hole to Adjacent Hole |

±.0005 |

| First Row Bushing Hole Location from Datums |

±.001, ±.002 (Epoxy Mineral tombstones) |

| Bored or Precision Bushing Hole Spacing (non accumulative) |

0-10 ±.0005, 10-20 ±.0008, 20-30 ±.0010, 30-40 ±.0012

(for aluminum, add 50% to these tolerances) |

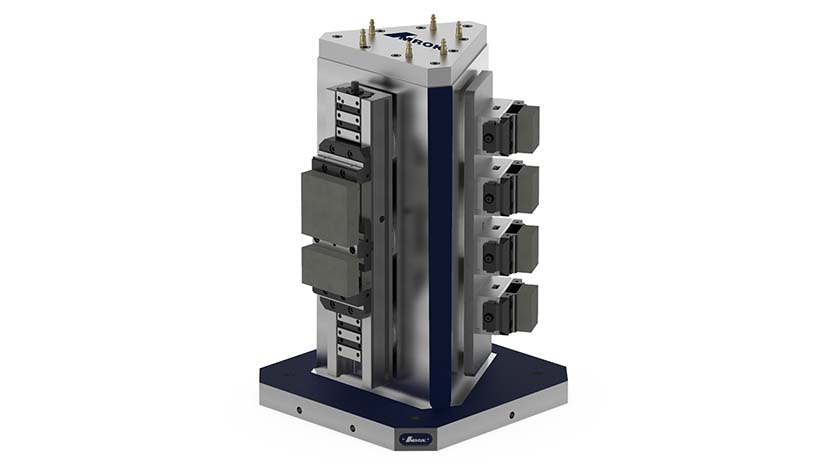

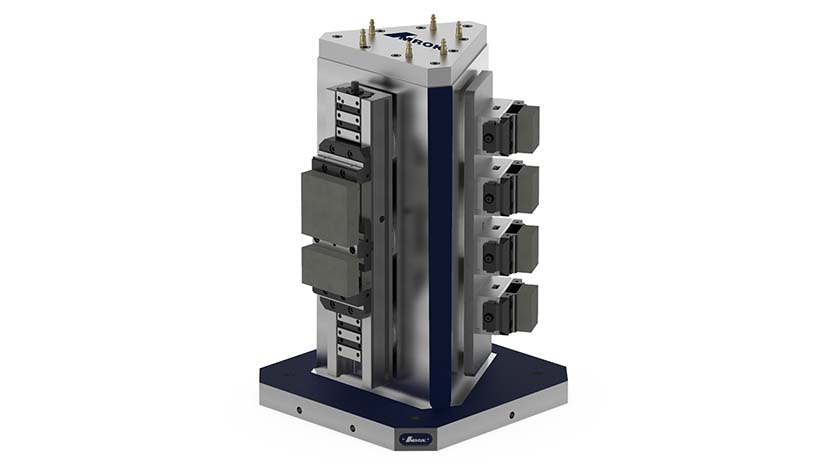

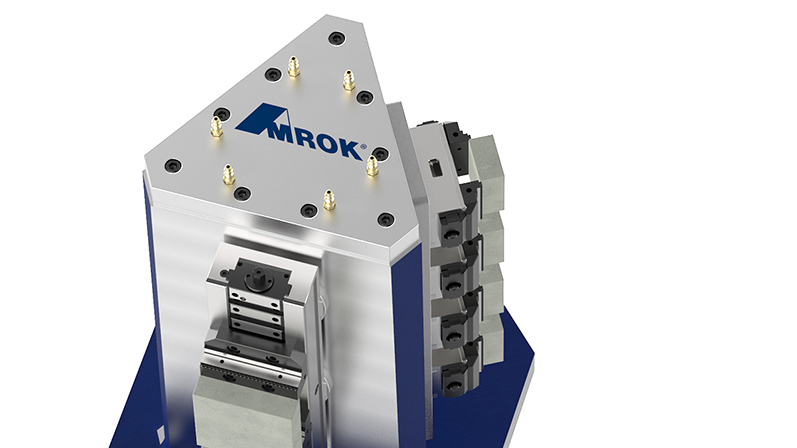

AMROK Hexagon Tombstone with Triag Modular Workholding

AMROK Hexagon Tombstone with Triag Modular Workholding

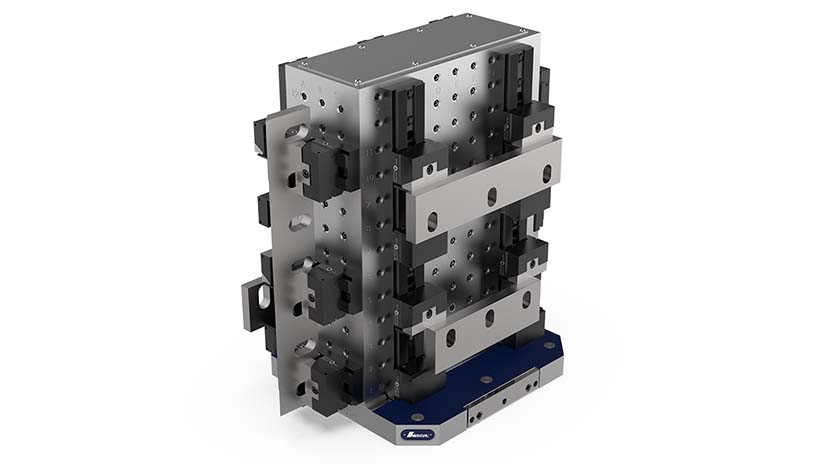

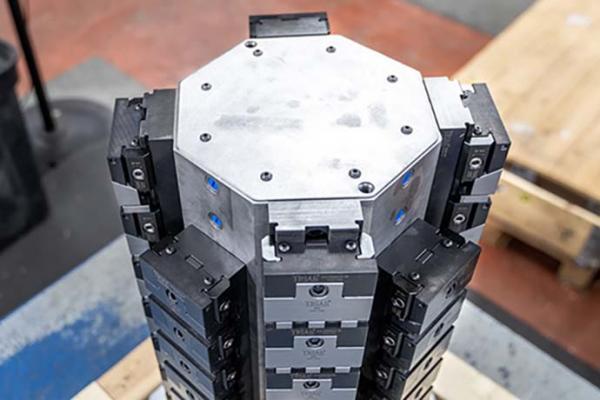

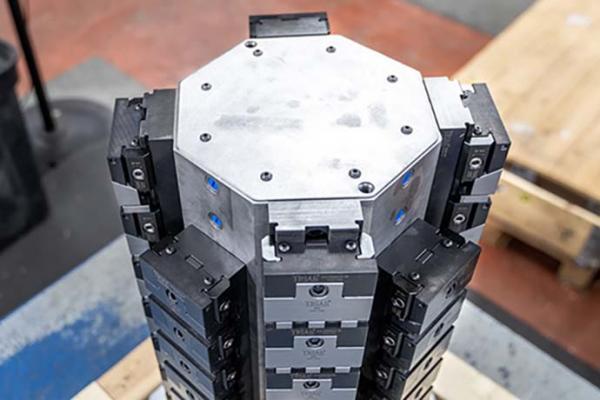

AMROK Octagon Tombstone with Mitee-Bite Uniforce Clamp

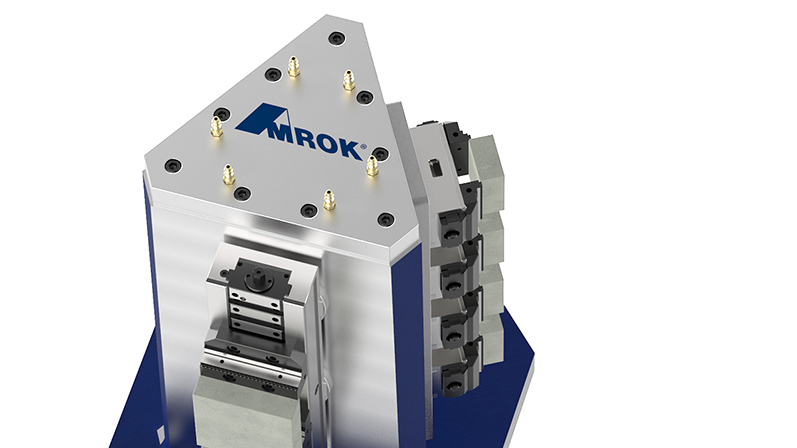

AMROK Triangle Tombstone with Schunk Vero-S Workholding

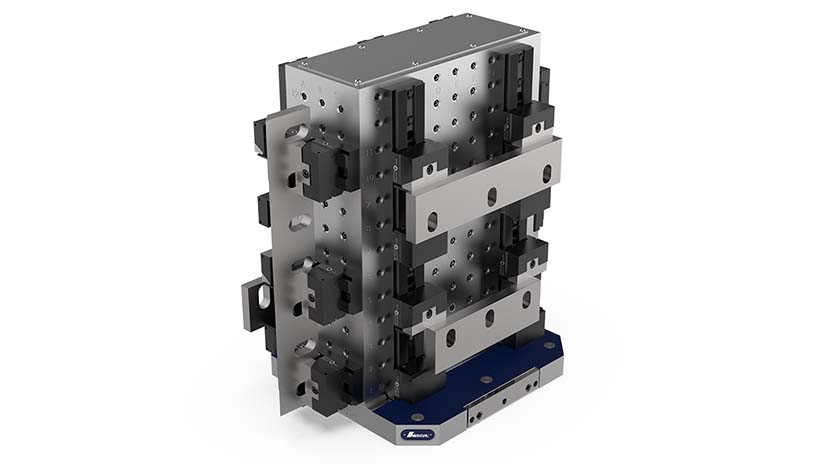

AMROK Cross Tombstone with Triag Modular Workholding

AMROK Cross Tombstone with Triag Modular Workholding

AMROK Double Angle Tombstone with Triag Modular Workholding

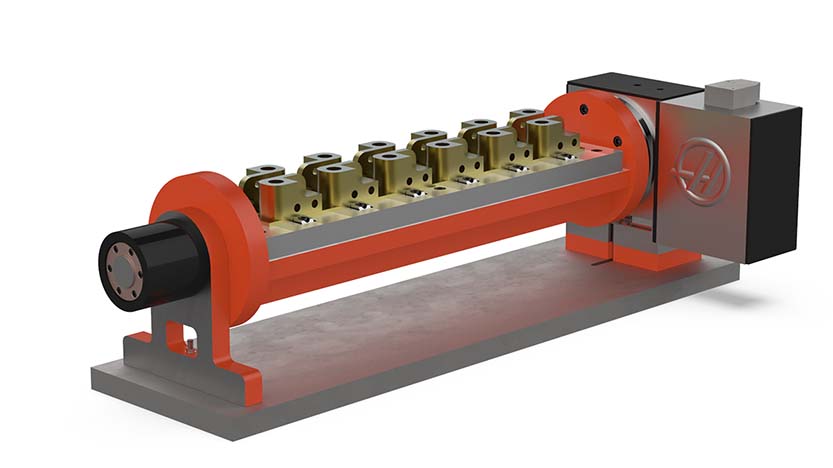

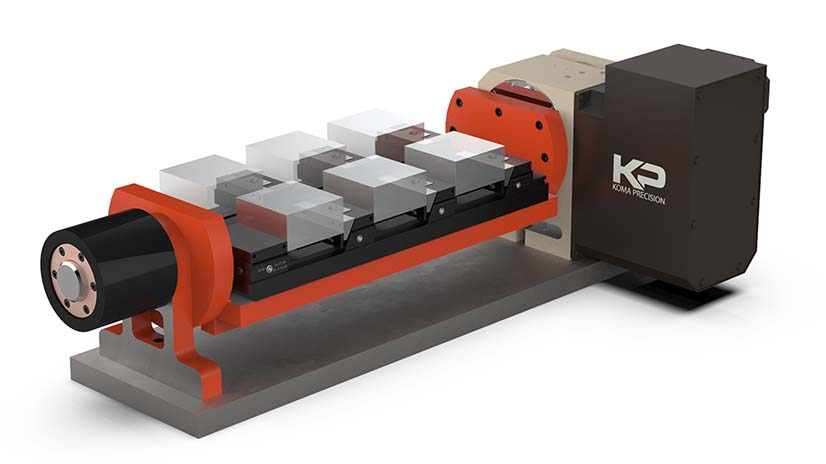

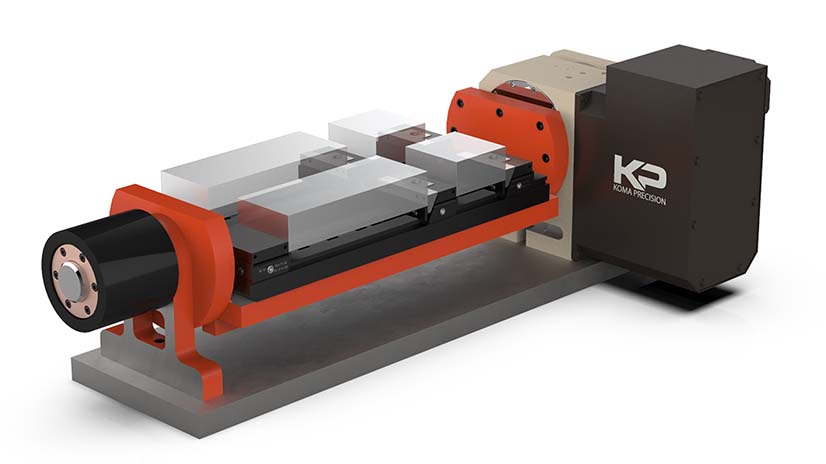

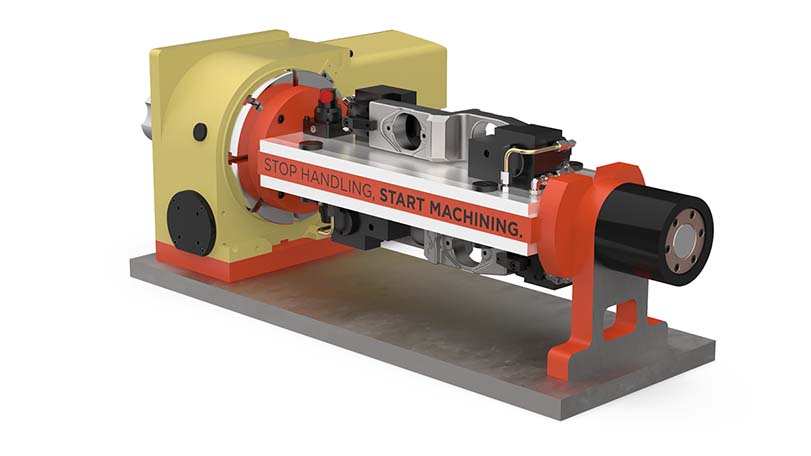

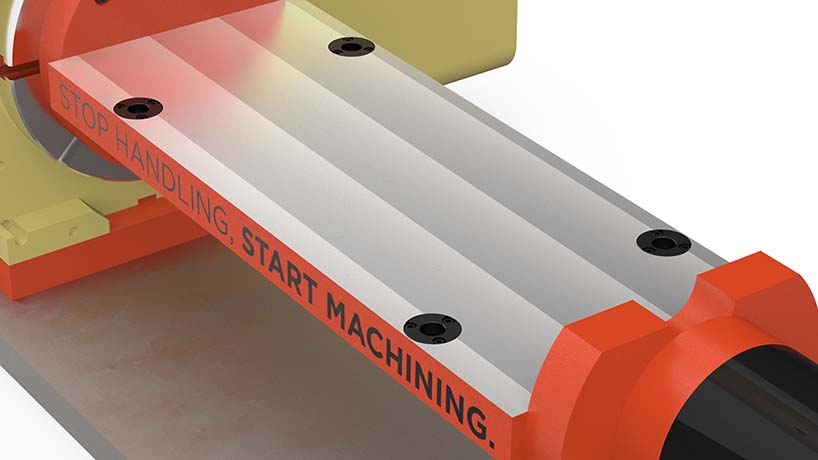

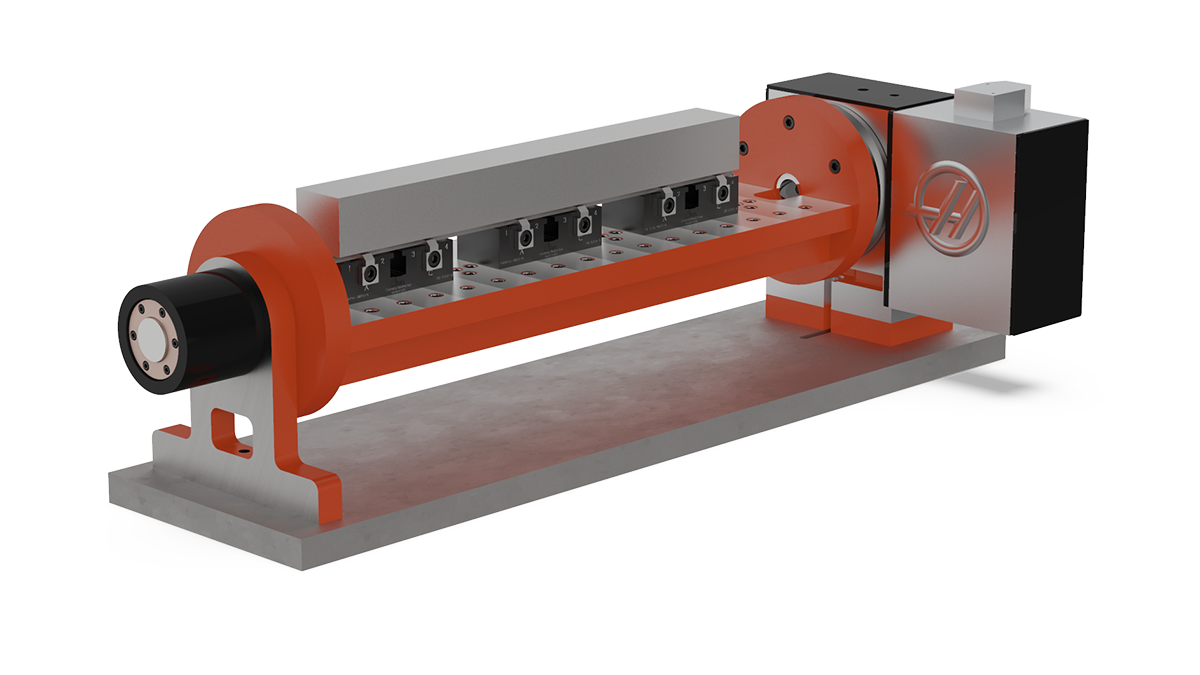

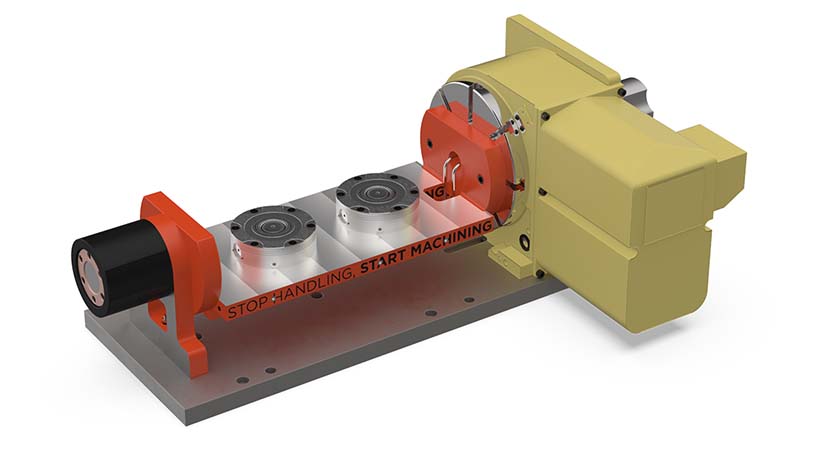

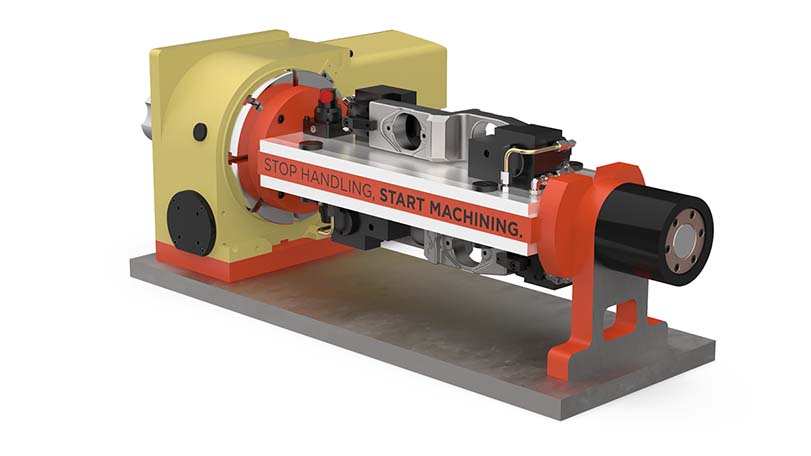

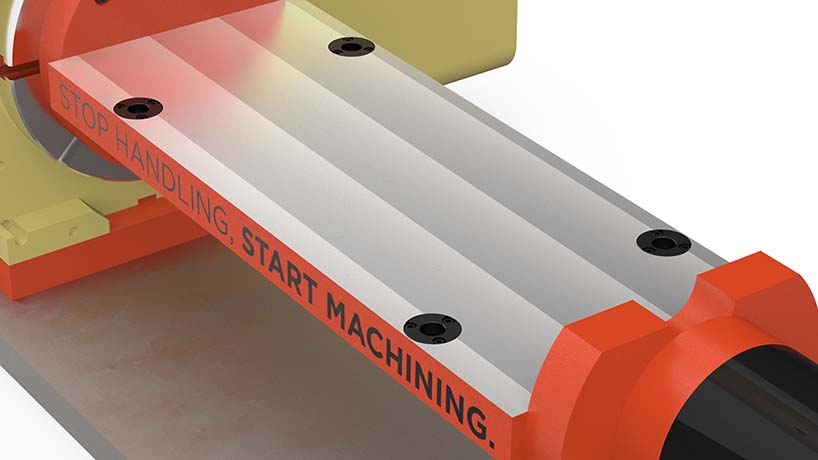

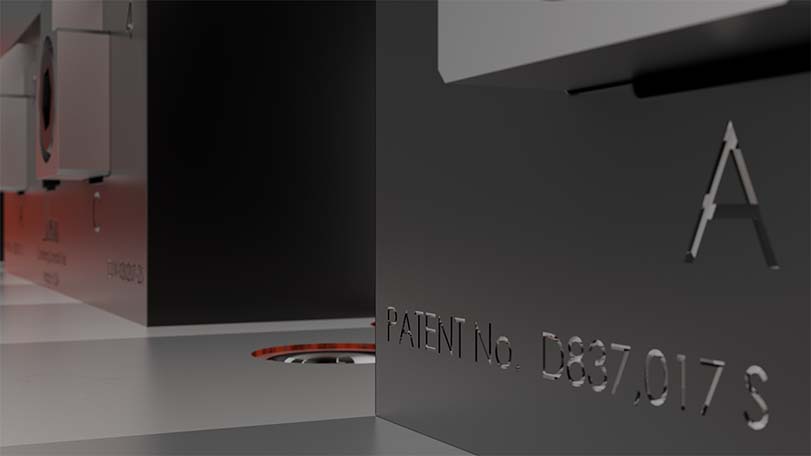

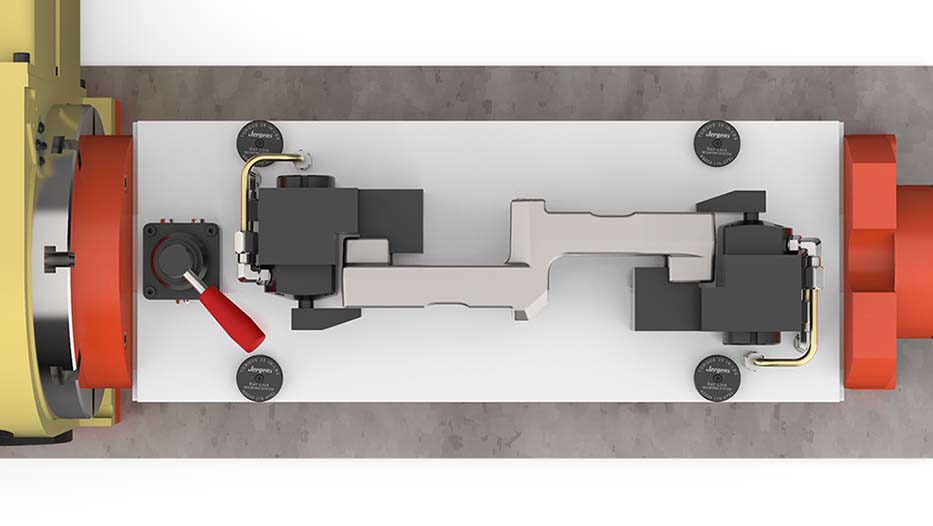

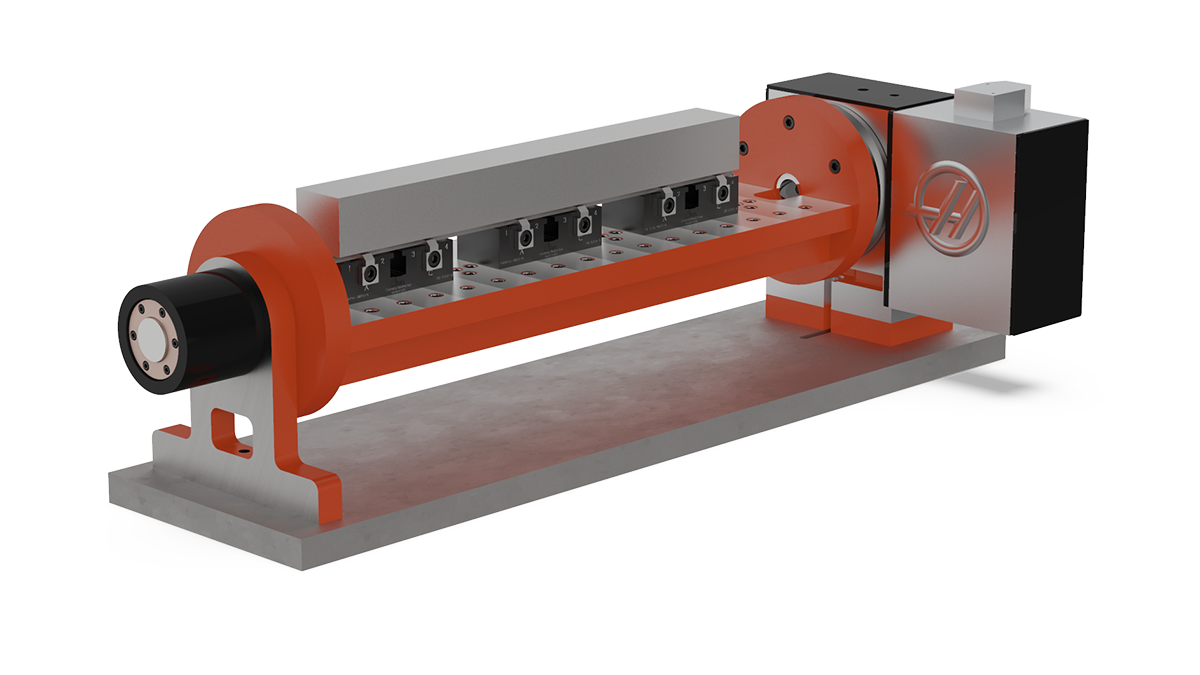

Martin Trunnion Stallion Trunnions with Mitee-Bite Pitbull Clamps

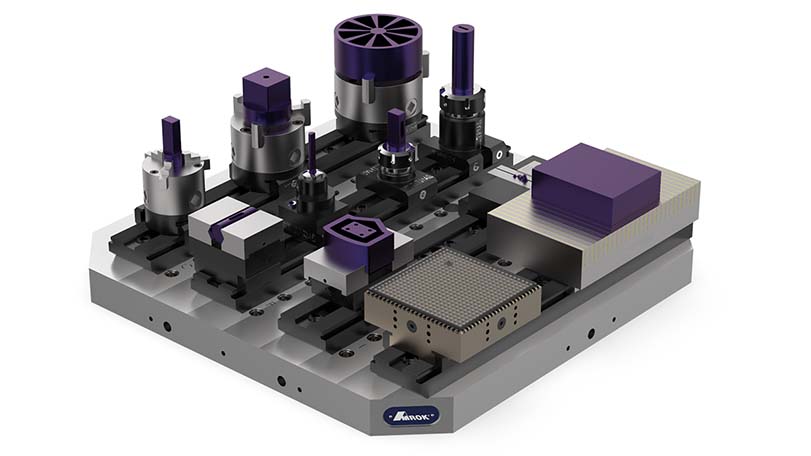

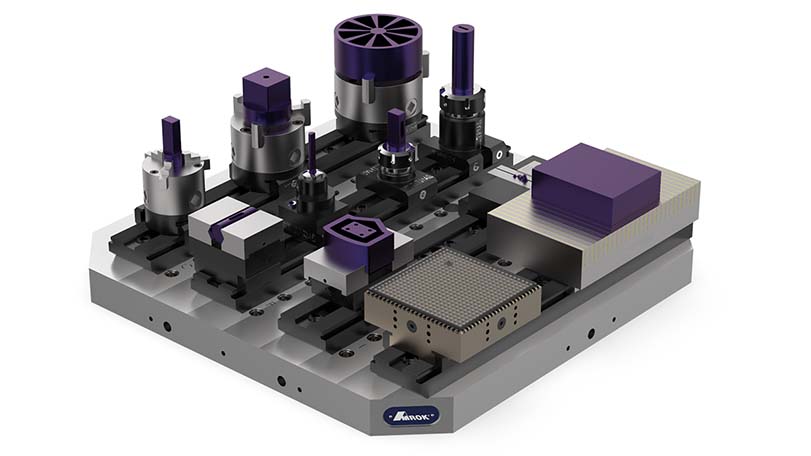

AMROK Rectangular Fixture Plate with Mitee-Bite Workholding

AMROK Cross Tombstone with 5th Axis Double Station Vise

AMROK Rectangular Fixture Plate with Triag Modular Workholding

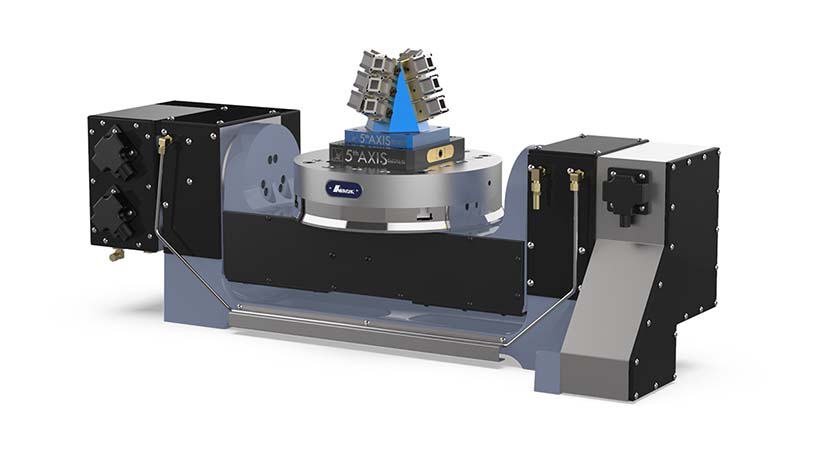

AMROK Circular Grid Plate with 5th Axis Top Tooling

AMROK Circular Grid Plate with 5th Axis Top Tooling

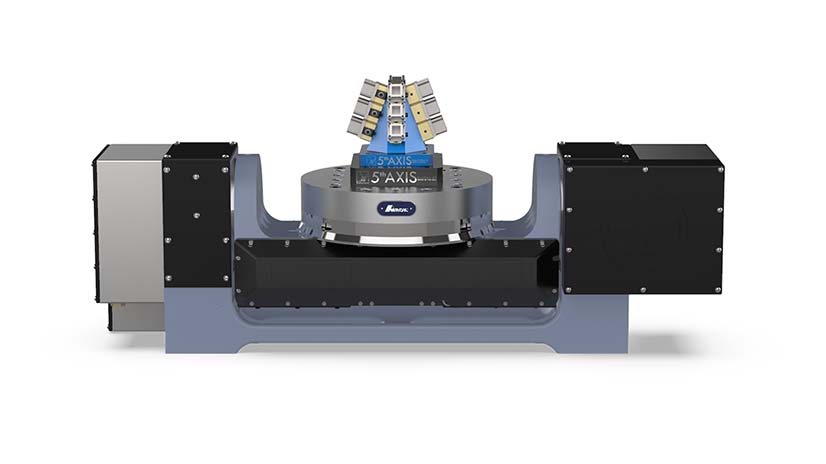

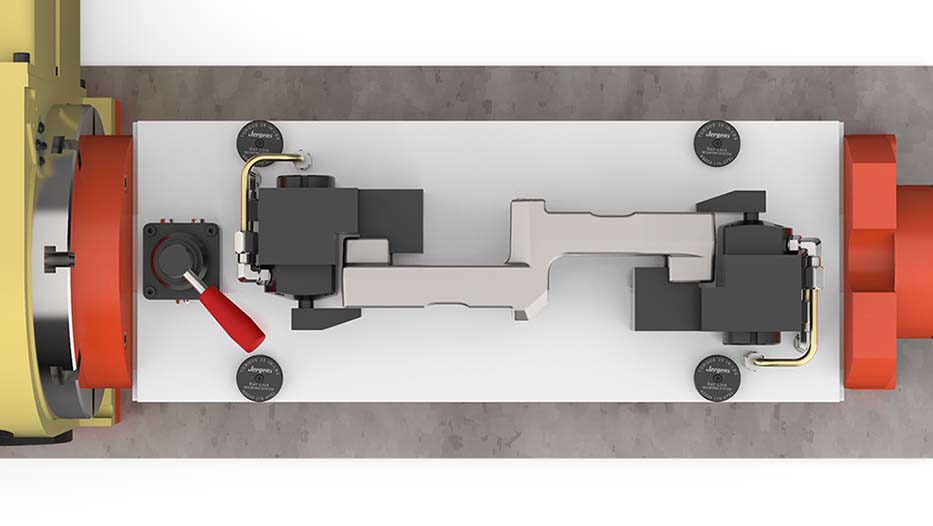

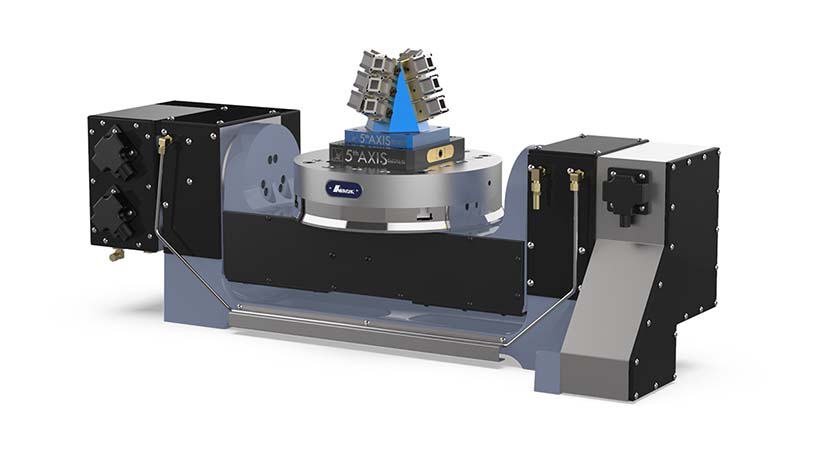

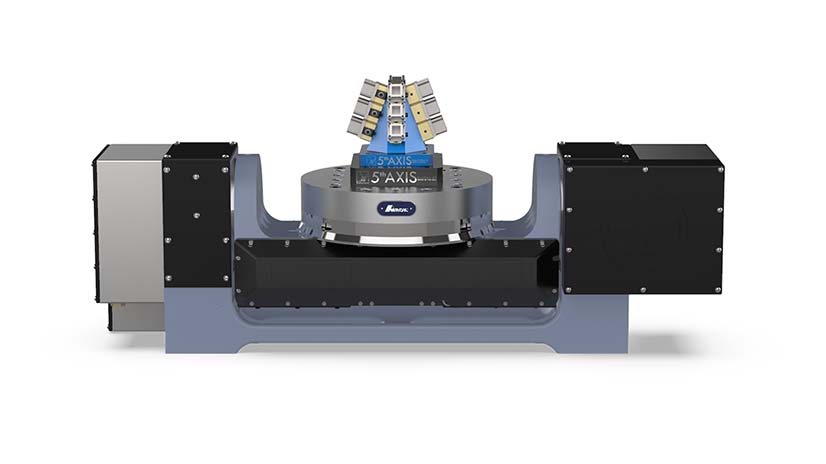

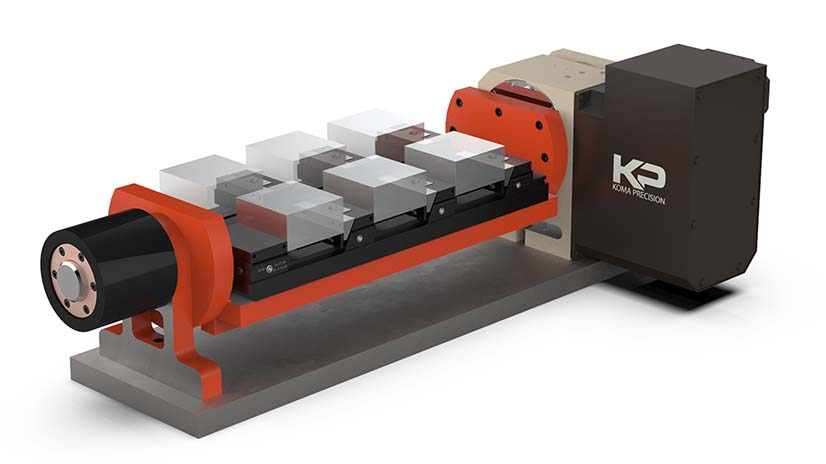

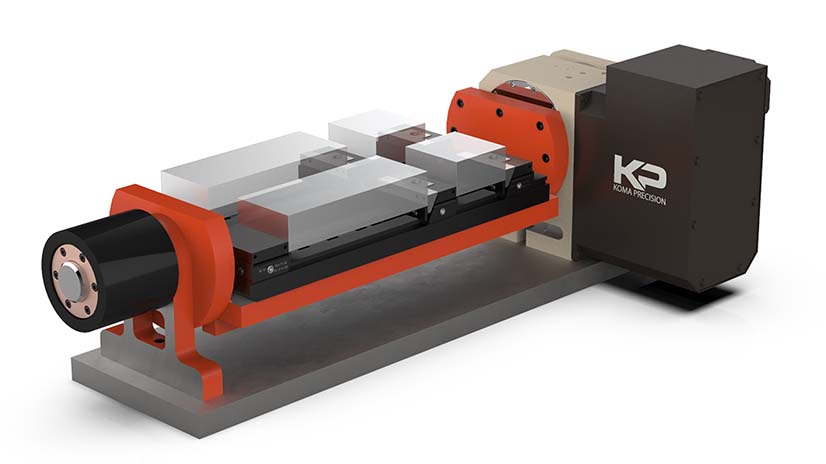

Martin Trunnion Stallion Trunnions with Triag Modular Workholding

Martin Trunnion Stallion Trunnions with Triag Modular Workholding

Martin Trunnion Stallion Trunnions with Triag Modular Workholding

Martin Trunnion Stallion Trunnions with Triag Modular Workholding

Martin Trunnion with Vektek Workholding

Martin Trunnion with Vektek Workholding

Martin Trunnion with AMROK Centering Dovetail Vise

Martin Trunnion with AMROK Centering Dovetail Vise

Martin Trunnion with AMROK Centering Dovetail Vise

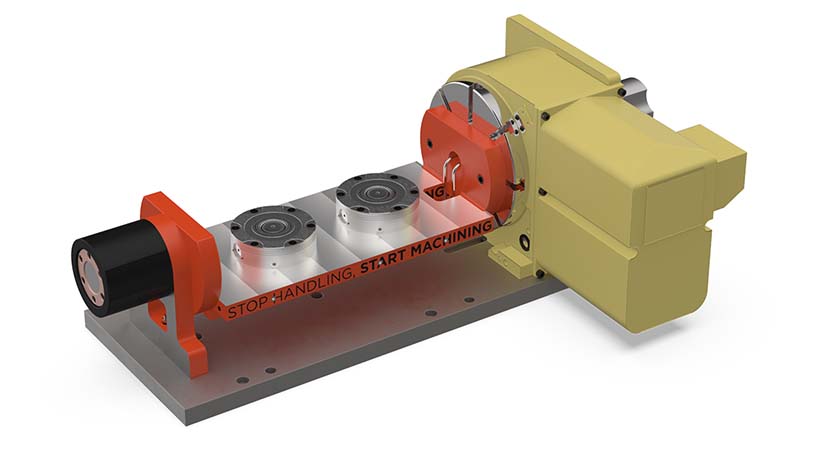

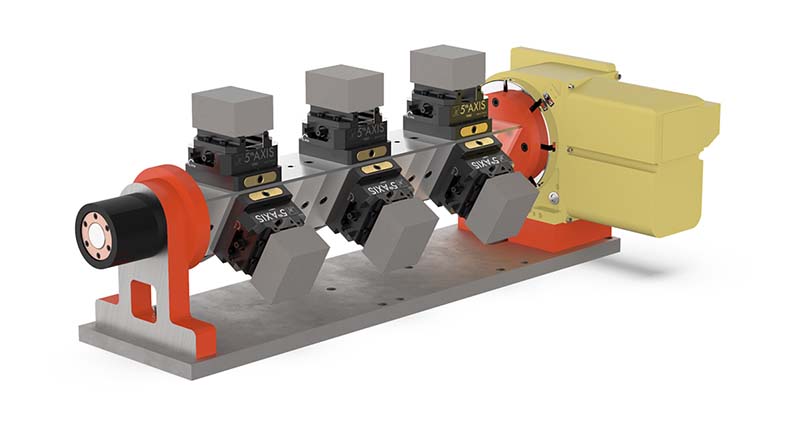

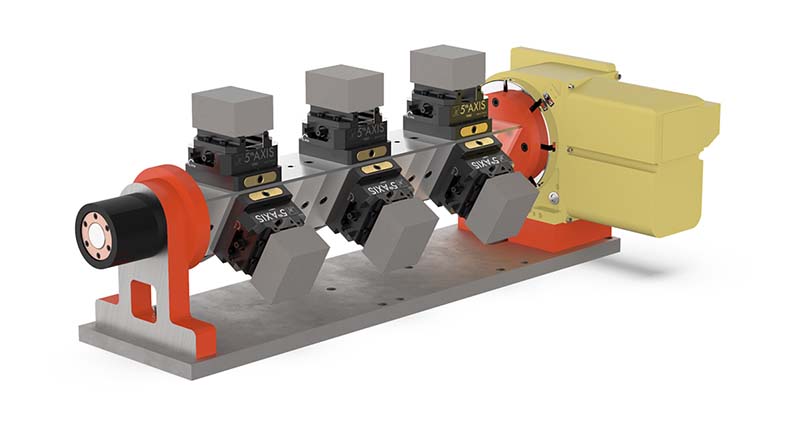

Martin Trunnion 4th Axis Tombstone Fixture with 5th Axis Self-Centering Vises

Martin Trunnion 4th Axis Tombstone Fixture with 5th Axis Self-Centering Vises

AMROK Triangle Tombstone with Schunk Vero-S Workholding

AMROK Triangle Tombstone with Schunk Vero-S Workholding

AMROK Octagon Tombstone with Mitee-Bite Uniforce Clamps

Martin Trunnion with Vektek Workholding

Martin Trunnion with AMROK Centering Dovetail Vise

AMROK Hexagon Tombstone with Triag Modular Workholding

AMROK Hexagon Tombstone with Triag Modular Workholding

AMROK Hexagon Tombstone with Triag Modular Workholding

AMROK Hexagon Tombstone with Triag Modular Workholding

AMROK Hexagon Tombstone with Triag Modular Workholding

.webp)