Robot machine tending may be the solution to increasing your productivity and quality while solving the skills gap in your shop.

When you choose a RoboJob Mill-Assist or Turn-Assist, you choose the most user-friendly and reliable system on the market. Each system gets you more spindle utilization through an extremely flexible solution with a wide range of payload capacities and the ability to handle differing workpieces. To top it all off, your highly-trained machinists get to manage the robot while focusing their time and effort on more advanced tasks such as setup, programming, and inspection.

AME + ROBOJOB-USA = UNSTOPPABLE MACHINE TENDING

Working alongside our partners at RoboJob-USA, AME integrates CNC machine tending that pushes the limits on high-production part-loading. But, AME's value goes beyond an automation system. For a machine tending integration to succeed, a solid workholding setup is required. Let us take on the burden of all of it and ensure you have a smooth implementation.

ROBOJOB MILL-ASSIST SERIES

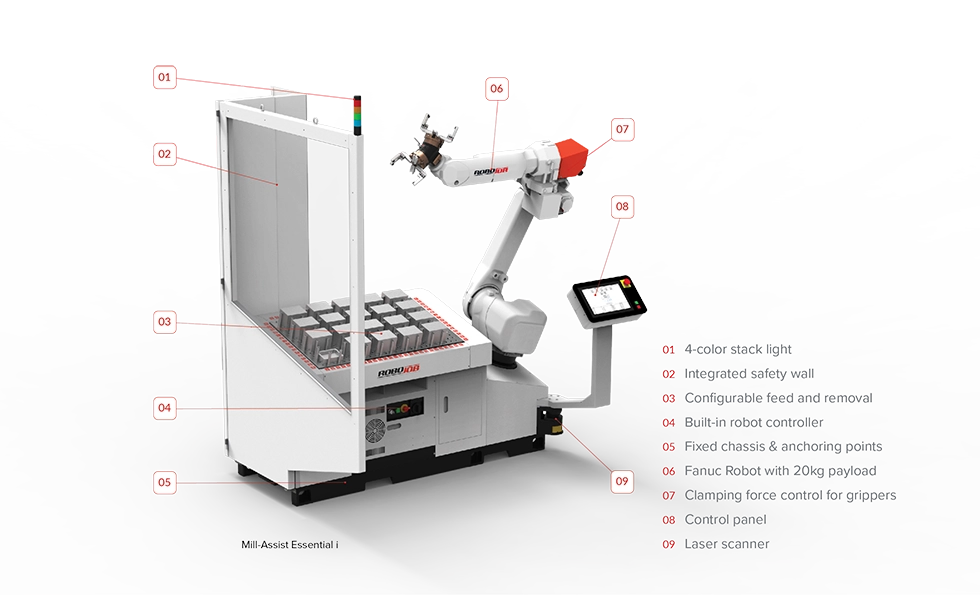

Mill-Assist Essential

The Mill-Assist Essential is an easy to use automation solution developed for loading and unloading various workpieces. Specifically developed for small runs or small workpieces. On the fixed Mill-Assist table, a stacker table allows for increased capacity and positional modularity.

- Workpieces up to a maximum length of 15.75”

- Fixed table with limited stacking height

- Robot payload: 44 lbs (20 kg) or 77 lbs (35 kg)

- Fully Integrated system

- Optional revolving unit to flip your parts

Robojob Turn-Assist Series

The RoboJob Turn-Assist Series is offered in three standard models with different weight capacities and workpiece diameter dimensions. These user-friendly systems are compact and easy to integrate automation into your lathe

Turn-Assist Essential

- Ideal for small runs

- Workpieces up to a maximum diameter of 15.75”

- Fixed table with limited stacking height

- Robot payload: 44 lbs (20 kg) or 77 lbs (35 kg)

- Fully Integrated system

Turn-Assist 200

- Ideal for small to medium sized runs

- Workpieces up to a maximum diameter of 7.88”

- Adjustable powered table for more capacity

- Robot payload: 26 lbs (12 kg) or 44 lbs (20 kg)

- Fully Integrated system

Turn-Assist 270

- Ideal for small to medium sized runs

- Workpieces up to a maximum diameter of 10.62”

- Adjustable powered table for more capacity

- Robot payload: 44 lbs (20 kg) or 77 lbs (35 kg)

- Fully Integrated system

LET'S TALK APPLICATIONS

The more we know about your application, the better we can maximize your operations. Chat with one of our AME experts today.