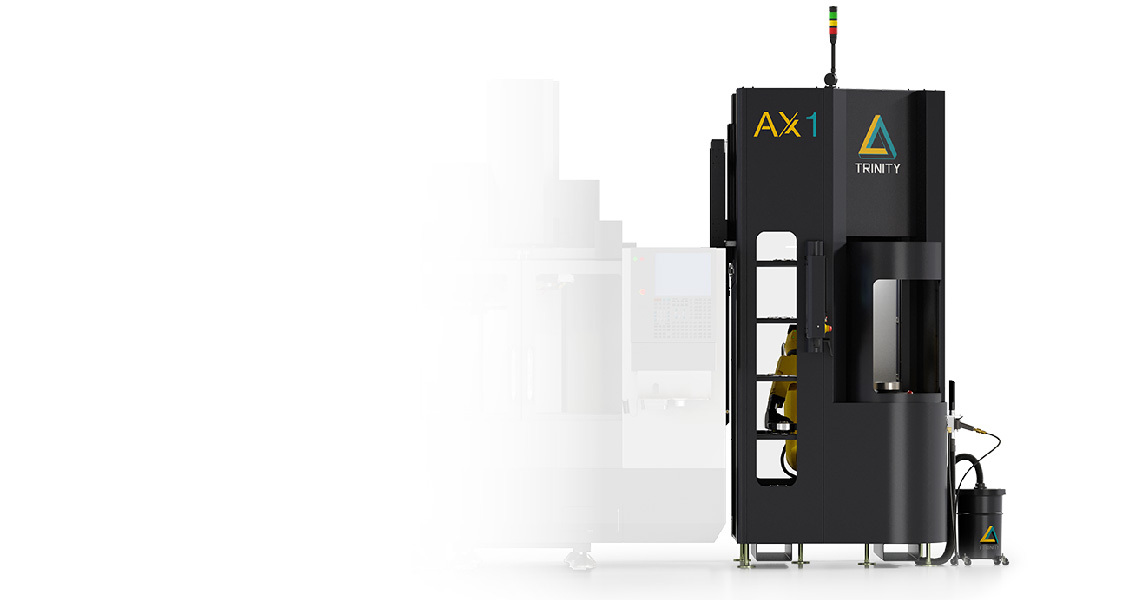

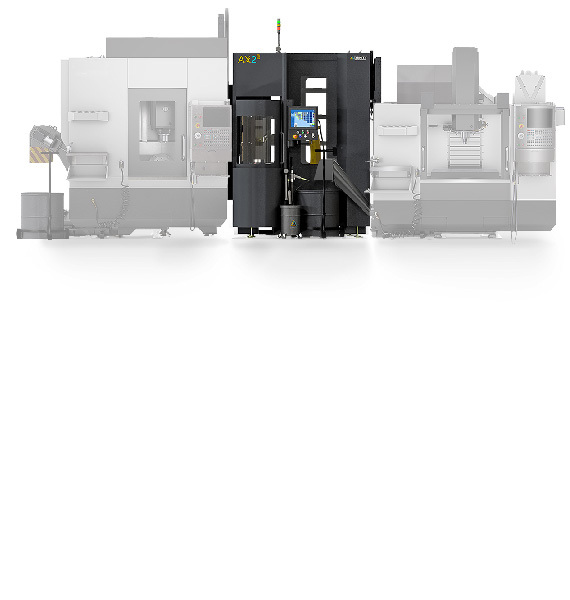

AX1 Pallet Delivery System

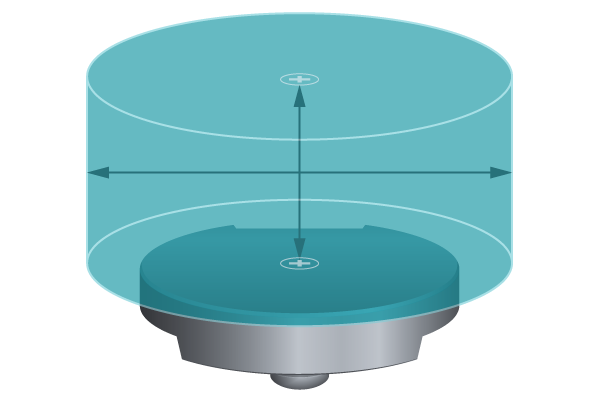

AX1-14

Pallet Locations: 14

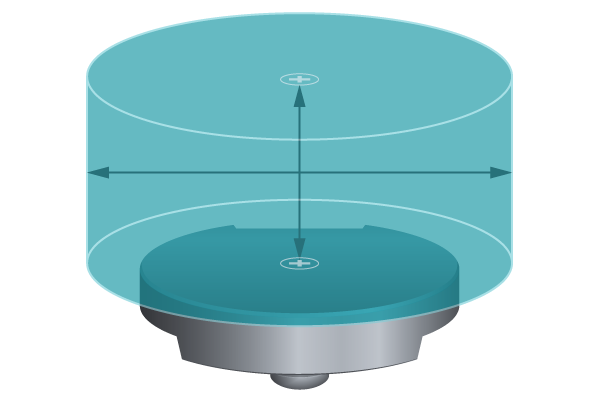

Max Part Size: ∅12" x 9"H

Max Capacity = 17 lbs

(Work Holding + Work Piece)

AX1-28

Pallet Locations: 28

Max Part Size: ∅8" x 9"H

Max Capacity = 17 lbs

(Work Holding + Work Piece)

Features

The AX1 is a high-speed, automated pallet delivery system designed to integrate with smaller CNC machines turning them into fully automated, lights-out production systems. The side-load design offers a small footprint that takes up minimal space on your shop floor. Each system includes installation and operator training over the course of 5 days..

- Fanuc M-10iD Robot with integrated Fanuc OEM 220VAC, 3-phase transformer

- 15" touch screen control with Trinity AXPM Software

Pallet System

- Pallet weight capacity: 17lbs

- Pallets designed for single clamping module

- Single-pallet operator station with rotating receiver

Complete CNC Table Setup Including

- Rotating receiver with single clamping module

- Integration into CNC table

- Controls package with clamp confirmation detection

- Air knife blow-offs for contact surfaces

- Autodoor installation

Power: 220VAC, 3-phase, 40A (Optional: 480VAC, 3-phase, 20A)

Air: 100-120psi, 60 SCFM