* In case impact noises due to excess pressure are audible when pressurizing the safety catcher, these can be suppressed by means of a flow control valve in the p-line.

** In case the pressure is not sufficiently constant (e.g. pressure drop at the beginning of a downward stroke), we recommend a check valve in the p-connection of the valve.

PRESSURE FLUIDS

To keep the clamping permanently open, safety catchers mostly are hydraulically actuated. Pneumatic versions are also available for smaller units.

- Hydraulic Actuation:Hydraulic oil (HLP) in accordance with DIN 51524-2:2006 must be used as pressure fluid. Please consult SITEMA before using any other fluids.

- Pneumatic Actuation:The compressed air must be dried and filtered. SITEMA recommends compressed air according to ISO 8573-1:2010 [7:4:4].

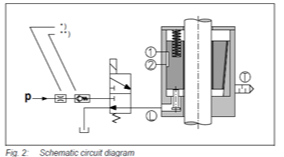

ACTUATION WITH A 3/2-WAY VALVE

In most applications an actuation as suggested in Fig. 2 is used. During every operational cycle, the 3/2-way valve is actuated electrically and releases the safety catcher.

In all other operational conditions, as well as in cases of power-failure, pressure line breakage, emergency stop, etc. the safety catcher becomes effective, secures the rod and/or stops the load. If necessary the valve can also be switched by another safety signal, e.g. speeding, contouring error, etc.

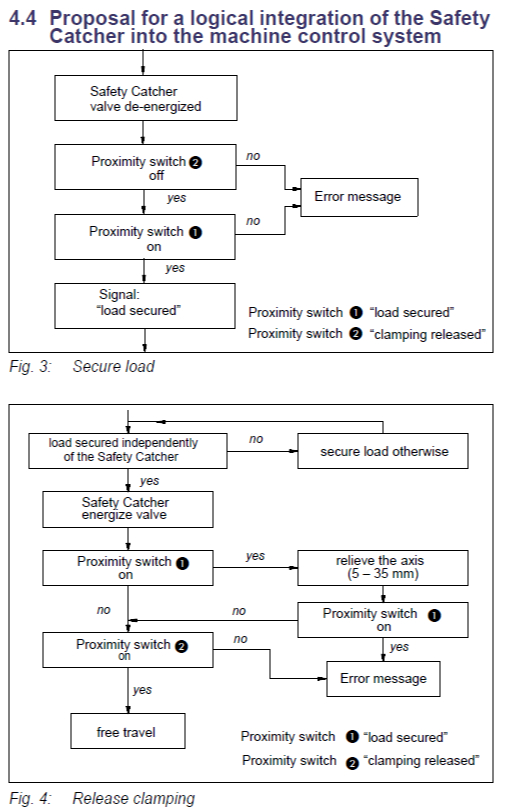

MONITORING BY PROXIMITY SWITCHES

Proximity switch 1 “load secured” signals the secure state and is used to authorize entrance to the danger zone.

Proximity switch 2 “clamping release” is used to activate the movement of the drive in the load direction.

For automatic detection of failures both signals are compared. In case both switches indicate the same state—apart from minor overlapping periods—there is a defect present.