How does consistent drawbar pull-force translate to improved machining outcomes?

Sep 19, 2023Drawbar pull-force can impact surface finish, tool wear, taper corrosion, machine downtime, and tool breakage. It’s vital to get tool clamping right.

Drawbar pull-force can impact surface finish, tool wear, taper corrosion, machine downtime, and tool breakage. It’s vital to get tool clamping right.

The Power-Check 2 Drawbar Pull Force Gage from OTT-JAKOB helps keep your machine spindle drawbar force in tolerance. Here’s why that’s so important.

.webp)

Choosing the wrong tool clamping system partner can be a serious mistake. Old-school CNC machine tool clamping solutions may need extra maintenance, experience shorter lives, and can even be hazardous to operators. So, what do we recommend?

We’re all familiar with the products of Industry 4.0--it encompasses the smartphones in our pockets and tire pressure monitors in our cars. Learn how OTT-JAKOB is bringing the fourth industrial revolution to your spindle.

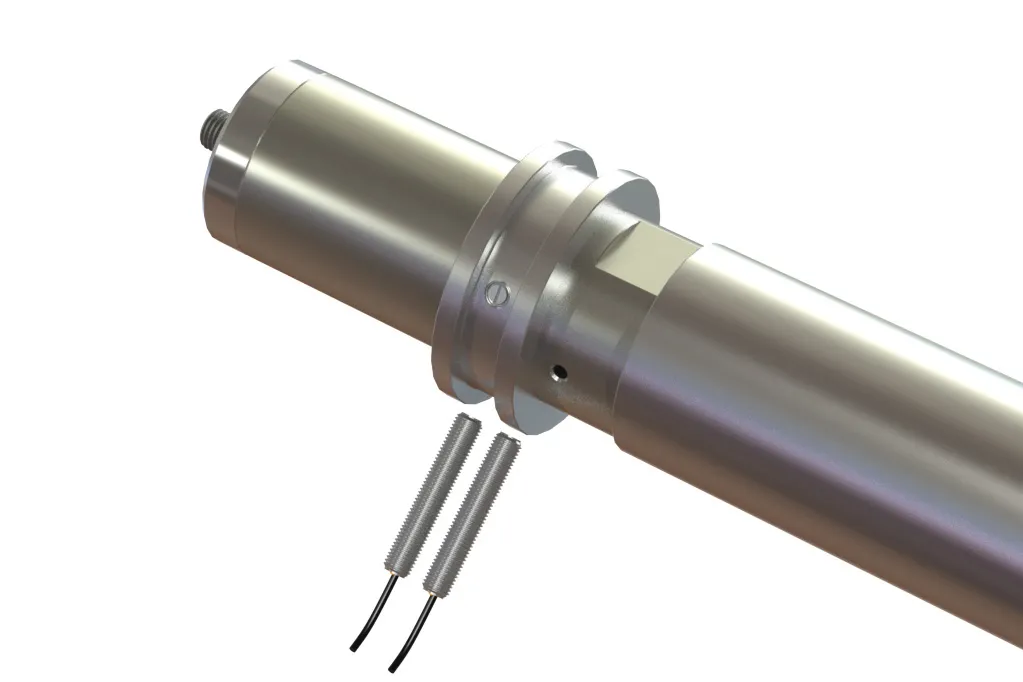

Mechanical position monitoring options for your drawbar shaft involve more manual work from the operator and can involve inaccurate results, while electronic options are more accurate, easier to install, and more compact.

Knowing your drawbar shaft position could prevent loss of precision, misclamping, and damage to the workpiece.

Leakage flow monitoring of the primary seal in the rotary union prevents damage to electrical components and bearing in the motor spindle, extending the service life of the drawbar and spindle.

A decline in drawbar clamping force produces micro-movements, vibrations, and other malfunctions in the machine that lead to poor machining results, rejects, and even machine breakdowns.

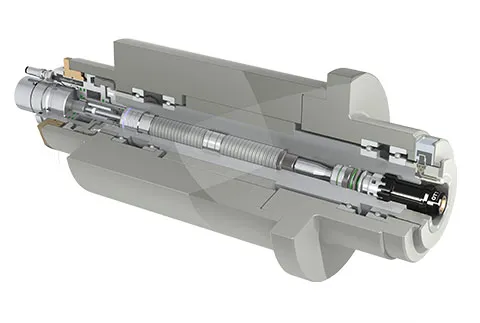

An MSU sensor system electronically provides preemptive maintenance that detects drawbar disruptions during the machining process.

Drawbar monitoring is essential for optimal spindle performance--it detects potential sources of disruptions, increases machine availability, and prevents unscheduled downtime.