Fixed and Movable Vises

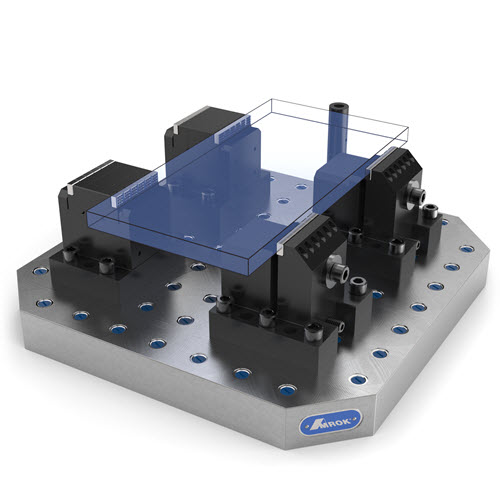

We believe in a simplified, modular approach, and understand that this is what keeps shops productive—which is why we created fixed and movable vises that work with a standard 2” grid.

How it’s done:

-

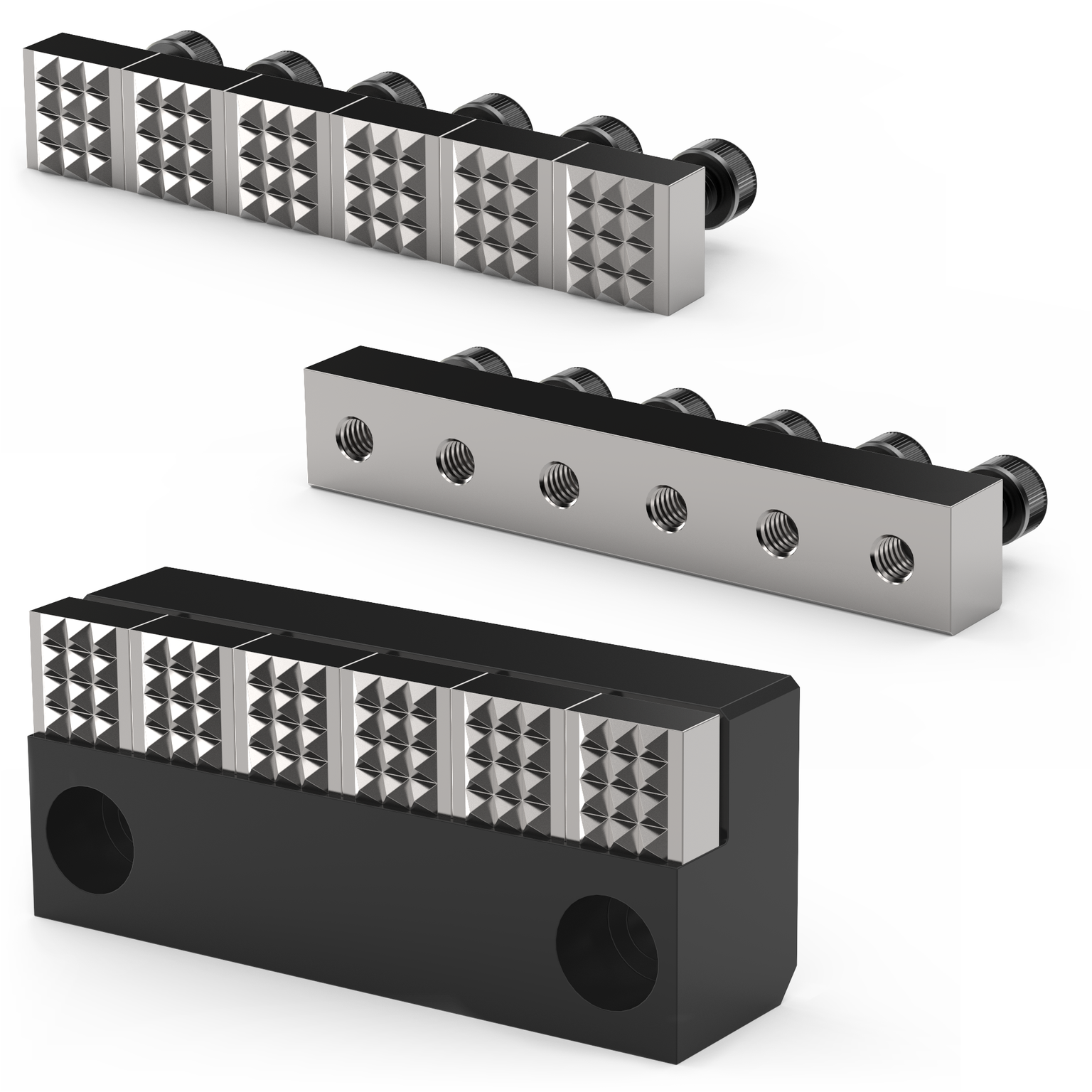

Choose between a smooth or serrated jaw face and install the vise on your fixture with precision locating screws.

-

Place the part to be machined, and clamp it with a movable vise equipped with the proper jaw face.

-

Start machining!

Find out if AMROK’s fixed and movable vises work for your application here. Stop searching, start machining.

- Black oxide finish

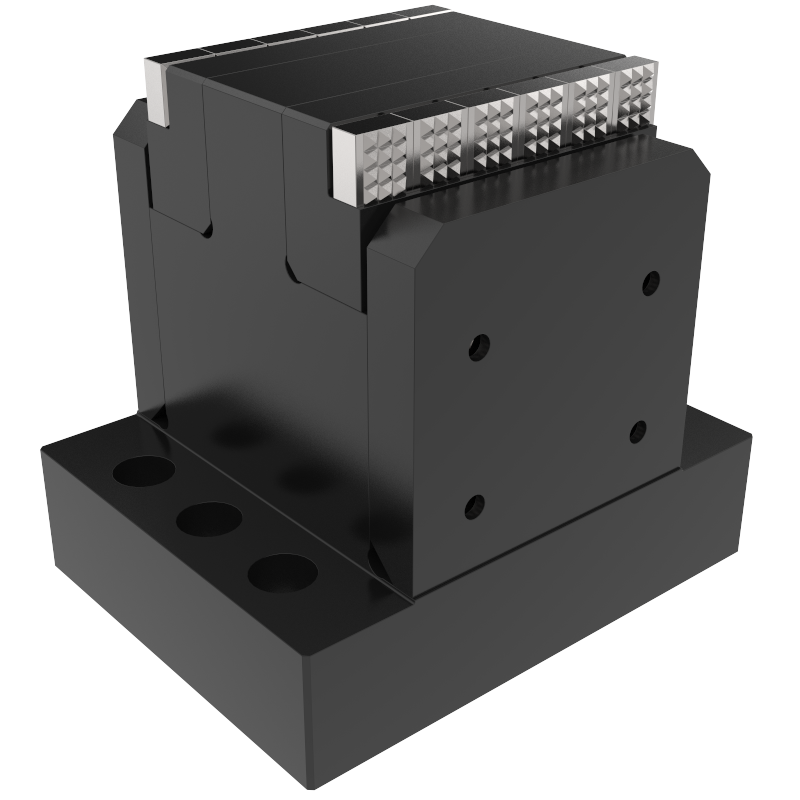

- Ten precision bushing holes (.5007/.5013 or .6257/.6263) allow for 1” movements of vise

- 5/16” minimum plate thickness for face milling applications, when using taller plate

- Designed for vxvxuse with fixed vises

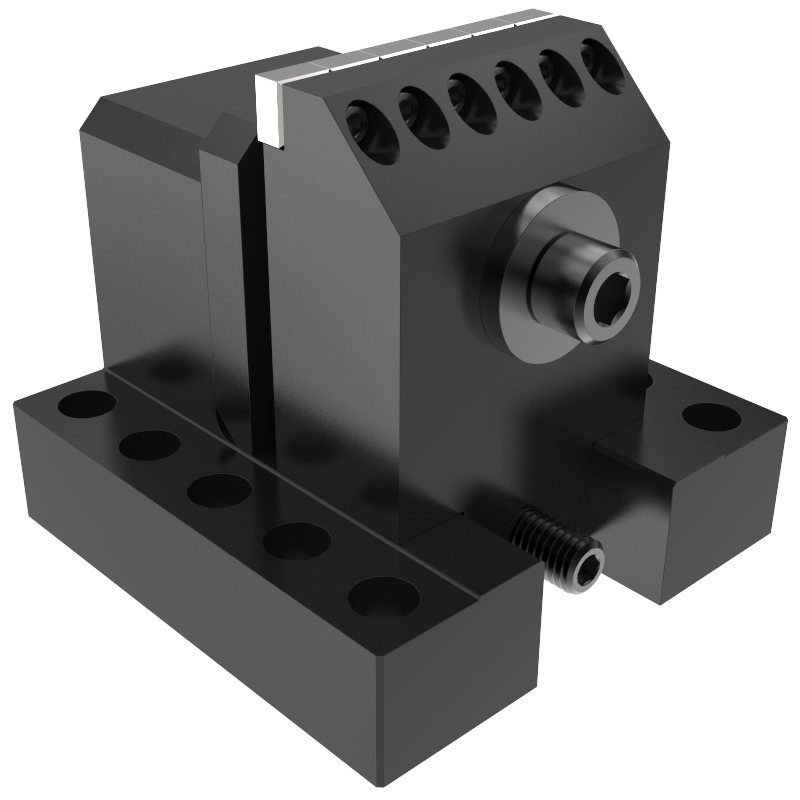

- Two precision dowel screws are used to locate vise on standard workholding grids

- 1/2” system locating screw: AMF-87994

- 5/8” system locating screw: AMF-87883