Vise Sets

- Home

- >

- Fixturing Components

- >

- AMROK Modular Workholding

- >

- Vise Systems

- >

- Vise Sets

Vise Sets

You want improved throughput and efficiency—in order to do that you need the peace of mind that your spindle will not crash while you are machining. Your current vises might not accommodate the clearance necessary, which could cause machine downtime.

This is why we offer vise sets that are designed to accommodate the required clearance, to prevent crashes.

Find out if AMROK’s vise sets work for your application here. Stop searching, start machining.

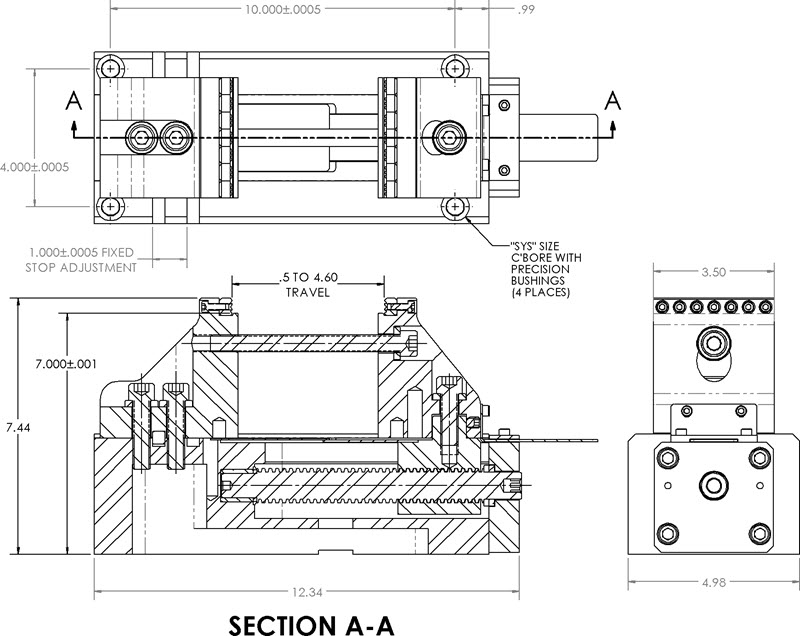

Note: Clamping widths accommodate between 0.05” and 4.60”. A minimum plate thickness of 5/16-inch is required for the face milling applications when using taller parallels.

Complete Vise Sets for Workholding

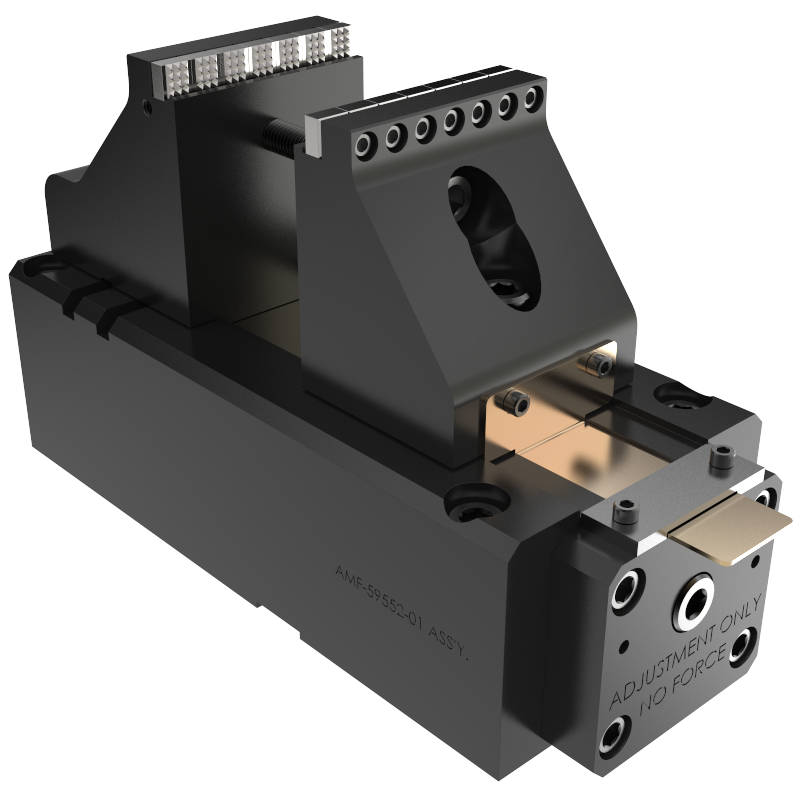

- Black oxide finish

- Four precision bushing holes (.5007/.5013) allow for quick and easy precision location of vise

- Thickness of parts (1/2” minimum for face milling applications)

- Two precision dowel screws are used to locate vise on standard grid patterns

- Jaw clamping widths from .5 – 4.60”

- 5” or 7” support height is great for horizontal mills, eliminating spindle clearance problems

- When needed, the fixed jaw may be moved 1” in order to change the spacing between jaw and grid

Loading products...