OTT-JAKOB Conditional Monitoring

EVERYTHING ALWAYS UNDER CONTROL

The early detection of disruptions in the manufacturing process is the main factor behind optimal machine availability. OTT-JAKOB condition monitoring systems for rotary unions identify potential sources of disruptions and prevent unscheduled machine downtime. Two reliable systems, leakage and wear monitoring, are available to continuously monitor the status of the spindle.

INTERNAL LEAKAGE MONITORING (1K-GD-CM)

The internal leakage monitoring is built into the rotary union. The two-tier sensor design detects liquids leaking in the sealing bushing and the flooding of the bearing inside the rotary union. The machine control system to which the sensor is attached can evaluate the data. As a component of the modular system from OTT-JAKOB, rotary unions with internal leakage monitoring can be installed with no adjustments having to be made.

The internal leakage monitoring is built into the rotary union. The two-tier sensor design detects liquids leaking in the sealing bushing and the flooding of the bearing inside the rotary union. The machine control system to which the sensor is attached can evaluate the data. As a component of the modular system from OTT-JAKOB, rotary unions with internal leakage monitoring can be installed with no adjustments having to be made.

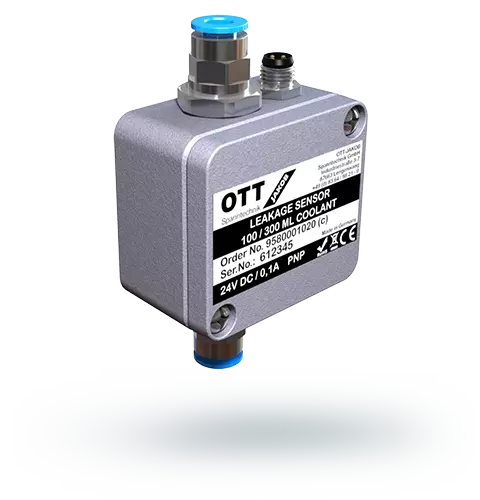

EXTERNAL LEAKAGE MONITORING

With external leakage monitoring, the sensor is positioned in a measuring device connected to the rotary union by a tube. If the predefined flow limit is exceeded inside the tube, a signal is emitted which appears directly on the measuring device or which can be sent to the machine control system. The external leakage monitoring can be added at a later date without replacing the rotary union and is also designed for use with rotary unions from third-party manufacturers. The sensor is designed to detect leaking coolant, hydraulic oil and water.

With external leakage monitoring, the sensor is positioned in a measuring device connected to the rotary union by a tube. If the predefined flow limit is exceeded inside the tube, a signal is emitted which appears directly on the measuring device or which can be sent to the machine control system. The external leakage monitoring can be added at a later date without replacing the rotary union and is also designed for use with rotary unions from third-party manufacturers. The sensor is designed to detect leaking coolant, hydraulic oil and water.

WEAR MONITORING (1K-GD-C)

The wear monitoring calculates the degree of wear of the rotary union seal. The built-in sensor logs the material removal rate with brittle particles (e.g. glass, stone, silicon) on the sealing bushing.

The wear monitoring calculates the degree of wear of the rotary union seal. The built-in sensor logs the material removal rate with brittle particles (e.g. glass, stone, silicon) on the sealing bushing.