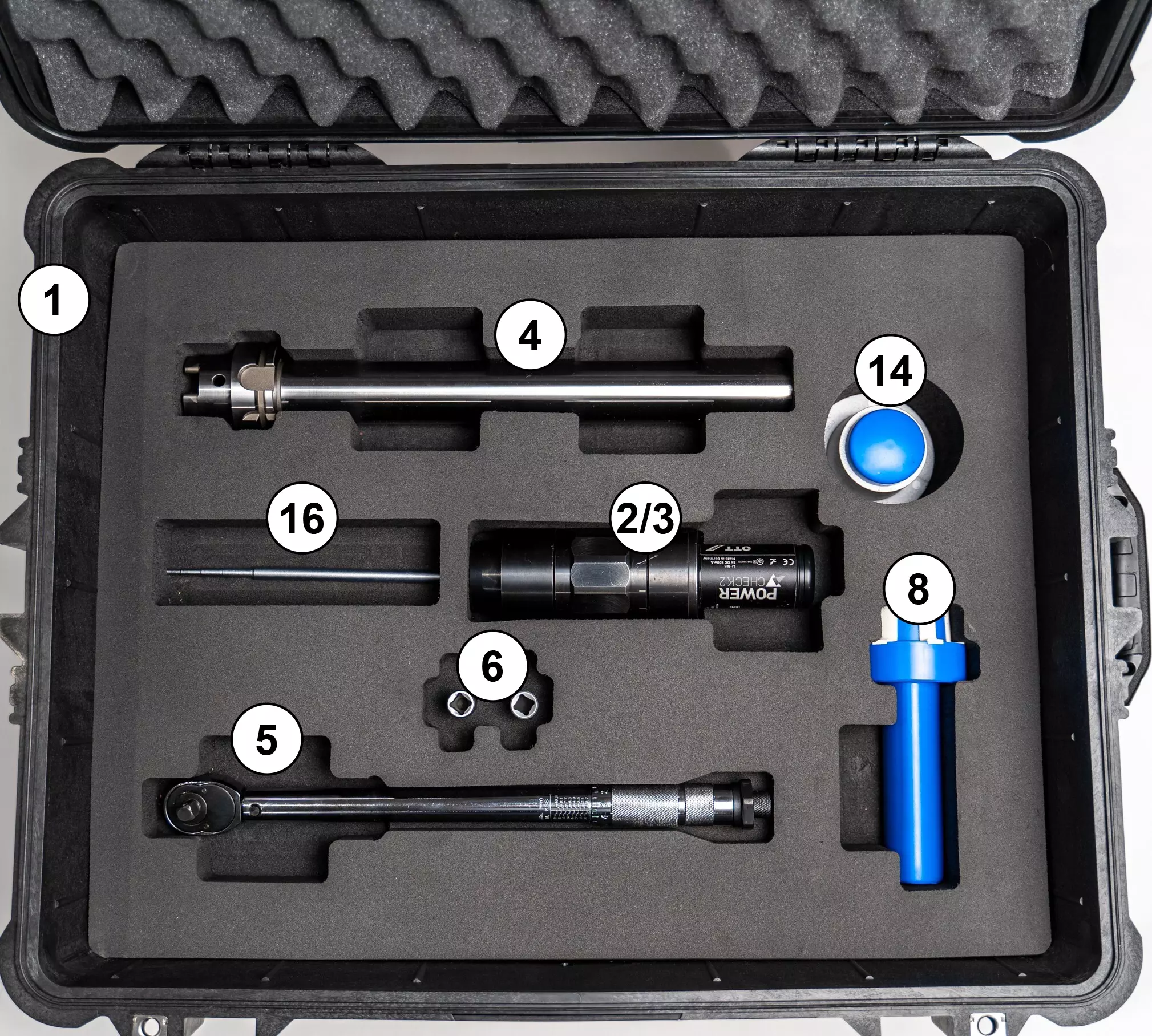

Tool Clamping Inspection Kit

When you rely on CNC machines to provide a service to your customers, preventative maintenance is key to keeping your machines running so you can deliver on your promise. At Advanced Machine and Engineering, the engineers in our Tool Clamping Systems division recognize that focusing on tool clamping maintenance is a simple way to catch various issues before they cause downtime. With over 30 years of experience in the field, our team has put together a customizable kit that puts this entire maintenance process in your hands to ensure early intervention of preventable issues.

- 1. Pelican carrying case w/ foam insert

- 2. OTT-JAKOB Power-Check 2

- 3. OTT-JAKOB HSK Adapter

- 4. HSK test arbor (mandrill)

- 5. Torque wrench

- 6. M5 Allen head socket

- 7. M5 T-handle Allen wrench

- 8. HSK spindle taper wiper

- 9. Metalflux Paste / O-rings (10 packets)

- 10. Digital depth gage

- 11. Dial test indicator

- 12. Magnetic Indicator Base

- 13. Power Check charging cable and software

- 14. HSK tool taper wiper

- 15. 24mm wrench

- 16. HSK adapter tool

Tool Clamping Inspection Kit

If you require inspection tools for multiple tapers, let us know in the comments.

Learn more about spindle inspection and maintenance

What is an MSU Sensor System for Drawbar Monitoring?

By: Harold Goellner, OTT-JAKOB Drawbar Specialist An MSU sensor system is a built-in, multi-sensor…

Top 5 Reasons to Choose OTT-JAKOB Tool Clamping Systems

Choosing the wrong tool clamping system partner can be an expensive and even dangerous mistake. Old-school…

How Drawbar Monitoring Saves You from Loss Productivity and Downtime

By: Harold Goellner, OTT-JAKOB Drawbar Specialist When it comes to machine tools, the spindle is the…