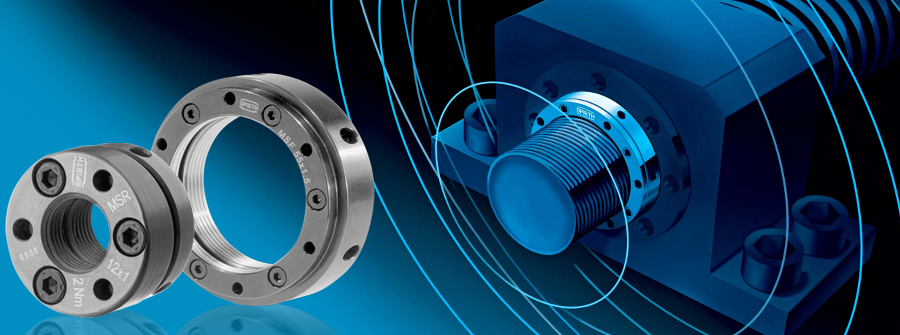

Precision Locknuts

Best Concentricity Results on Spindles

Thanks to their perfect functionality, they easily overcome the increasing dynamic demands and power densities of modern machine designs – and are thus developed with operating efficiency in mind. Spieth locknuts are available in various different versions.

Spieth locknuts show their strength when "things are really moving." They ensure optimum concentricity on spindles. The combination of production precision and the diaphragm system developed by Spieth gives the locknuts their unique performance capacity.

The relevant functional supports, such as the load thread, locking thread, and end face are inseparable components of the body of the nut and are produced in a single setting with high precision. The diaphragm lock ensures that this precision is achieved when assembled in your application result and that it is also retained throughout its operation.

Areas of Application and Examples of Use

Spieth locknuts are used in all sectors of mechanical engineering. Precision, reliability, rigidity, and ease of use are key aspects in the design of a threaded connection. Spieth nuts are always the first choice whenever at least one of these aspects is required – for example:

- In chipping, forming, and cutting machine tools

- In handling and automation technology

- In conveyor technology

- In general drive technology and transmissions

- In fixture construction

- In packaging machinery

- In compressors and pumps

- In printing machinery and paper technology

- In textile machinery

- In woodworking machinery

- In press construction

- In process technology for mixing, crushing, and centrifugation

- With measurement, control, and testing technology

Locknut Catalog Locknut Inch Part List

MSR - Standard Locknuts

Can be freely, infinitely and exactly positioned. Reliable locking without additional grooves or locking plates. Quick and precise assembly and disassembly.

CAD SELECTION

MSR (Inch) – Standard Locknuts

Imperial locknuts designed with a thread range of 17mm x 32 threads/in to 200mm x 8 threads/in or 5/8” x 18 to 3” x 12.

CAD SELECTION

MSA - Reduced Face Contact Locknuts

MSA series locknuts with a reduced contact surface and some of which have smaller external diameters than the MSR series are particularly suitable for the assembly of angular ball bearings and cylindrical roller bearings (ISO diameter series 9).

CAD SELECTION

MSW - Heavy Duty Locknuts

Can be freely, infinitely and exactly positioned. Reliable locking without additional grooves or locking plates. Quick and precise assembly and disassembly.

CAD SELECTION