Safety Catchers

secure restraining in case of pressure drop

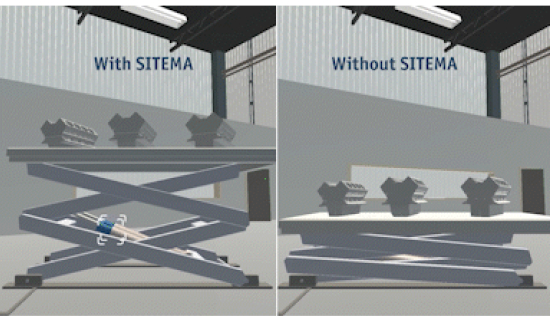

Safety catchers are used wherever heavy lifted loads have to be secured against falling or accidentally dropping. These safety catchers, or slide locks, have been evaluated and determined to have met the requirements of OSHA Directive CPL 02-01-043.

series k, kr, krp, and more

- Medium-sized, large, and very large loads

- DGUV-approved

- One load direction

who is best protected?

safety catcher vs ratchet

safety catcher vs ratchet

advantages | Safety Catcher

- Emergency braking possible

- Overload protection

- Stepless clamping

- Safety factor included

- Easy integration in all machines

- Safe against operating errors and accidental release

- Officially certified by European authorities

- Easy remote control and surveillance

- Standard solution with absolute functional safety, reliable and proven for more than 35 years

disadvantages | ratchet

- Usable only at standstill

- No overload protection

- Blocking only at given positions

- Safety factors to be considered

- Not fail safety

- Complicated

- Certification necessary

- Difficult control

- Special design necessary for each press type, ie. additional cost

personal protection and accident prevention

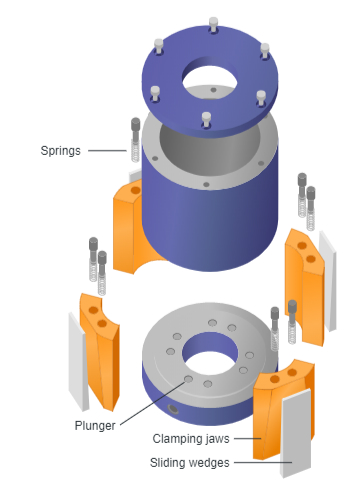

safety catcher design

The piston shaft is surrounded by the housing. Several sliding wedges are assembled inside the housing. Wedged clamping jaws move along the sliding wedges. The plungers hold the clamping jaws in raised position so that the shaft can move freely. In the released condition the springs are compressed.

safety catcher applications

- Closing Stroke Protection

- Hydraulic Elevators

- Broaching Machines

- Hydraulic and Other Presses

- Hydroforming

- Aerial Lifts

- Packing Machines

- Stack Loaders

- Molding Machines