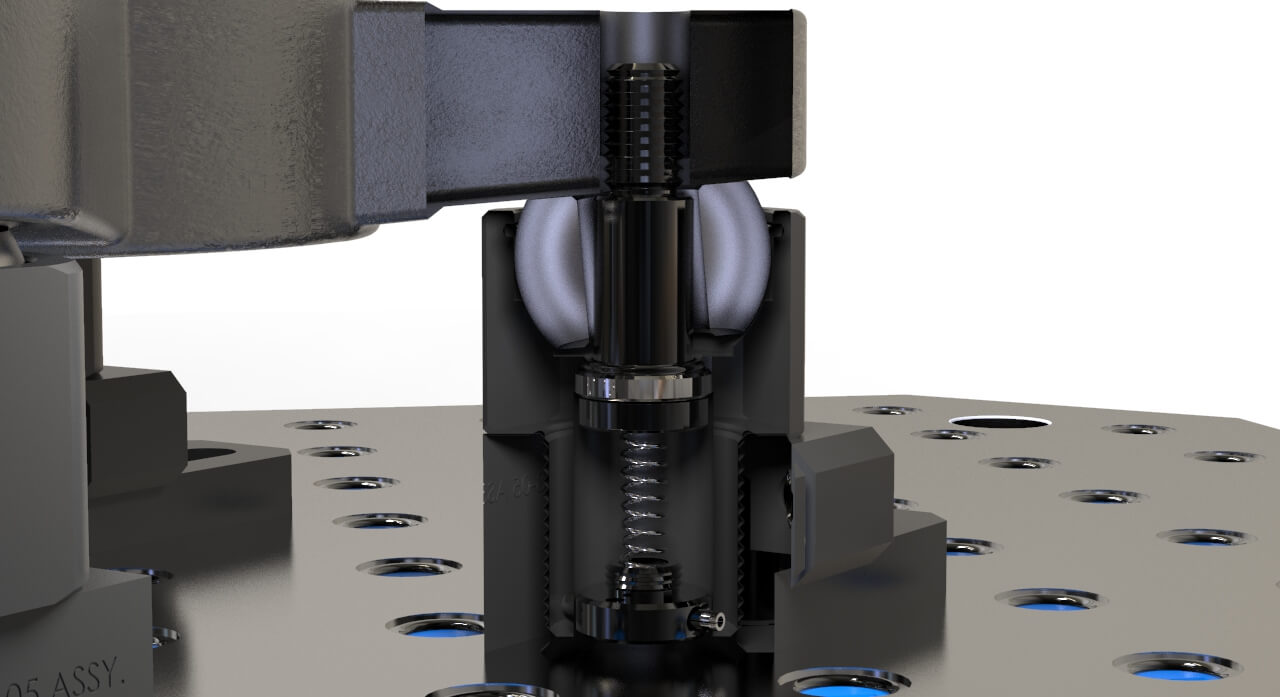

Inverted Stud Ball Element

Inverted Stud Ball Element Allows Full 5-Sided Machining

Advanced Machine & Engineering’s (AME) new patent-pending inverted stud ball element allows full, five-sided profile machining that decreases overall machine time for a variety of industries including aerospace, medical, and automotive.

This self-aligning fixture element (S.A.F.E.) features:

-

A ball element that has 6 degrees of rotation in any direction.

-

Swiveling ball element contact pads that allow less internal stresses for bent or angled parts requiring clamping for machining.

-

Viton O-Ring protection that prevents penetration of chips and coolant within the ball element system guaranteeing long life.

-

Fixed and adjustable threaded ball element heights.

-

Fixed Press Fit ball element heights for locating and positioning.

-

Custom sizes available upon request.

The ball element and stud combination provides a one-component design for stress-free clamping by conforming right to the part that is being machined.